Novel method for manufacturing base and bracket of stapler

A manufacturing method and stapler technology, applied in the direction of metal processing equipment, etc., can solve the problems of low material utilization rate, complex manufacturing process, and many manufacturing processes, and achieve the effects of fewer manufacturing processes, increased productivity, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

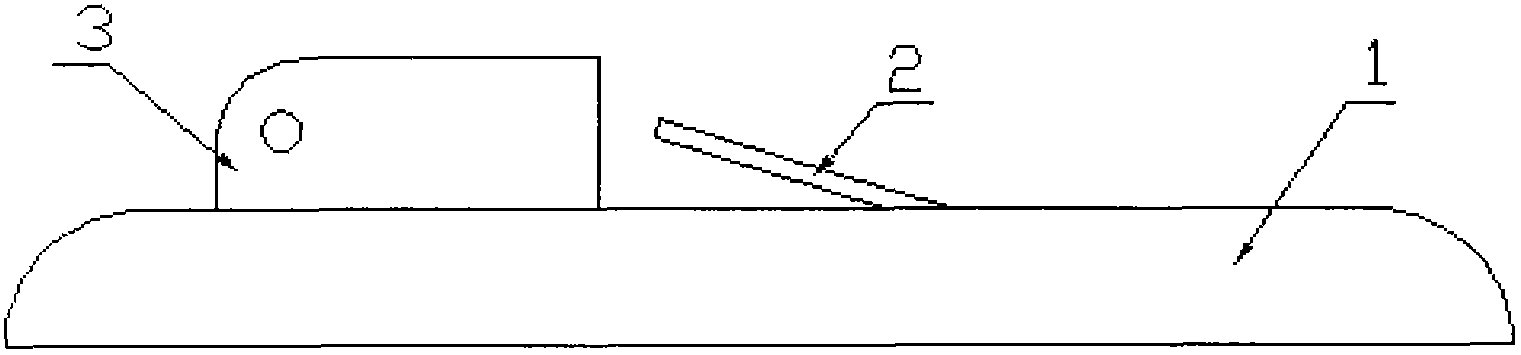

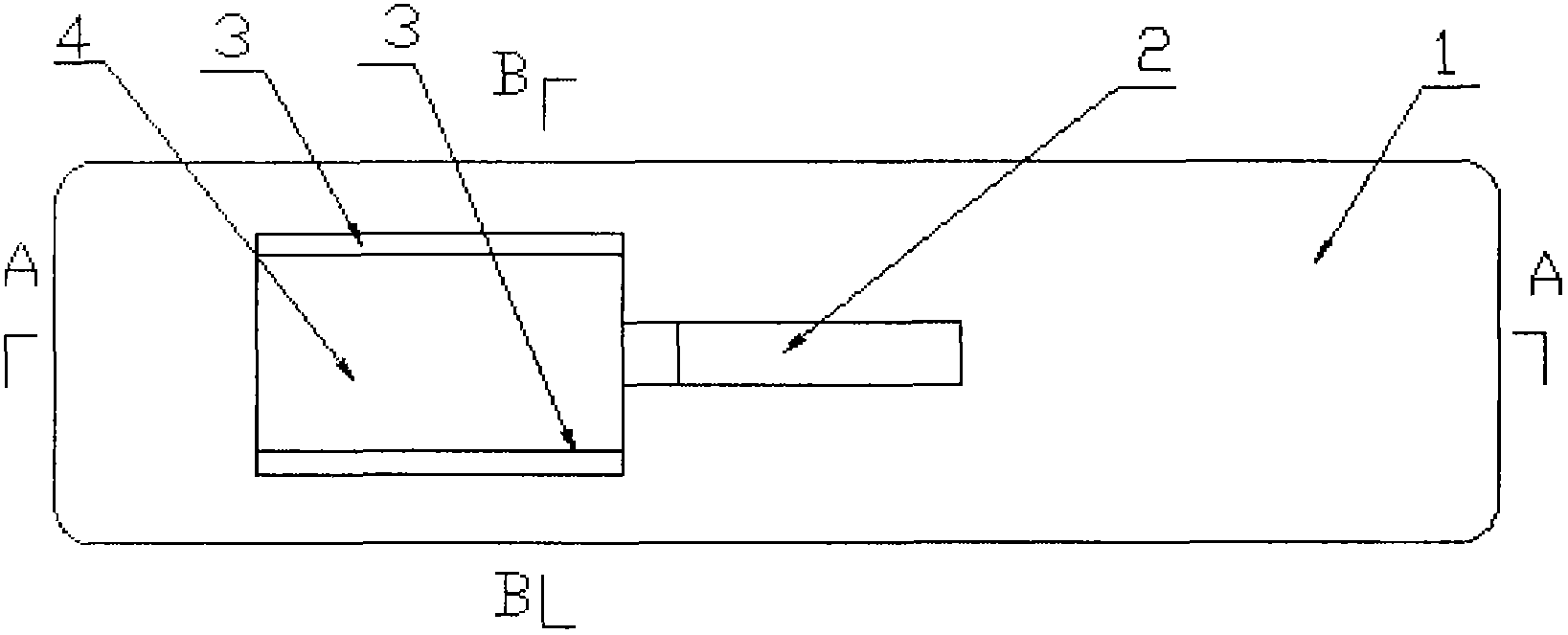

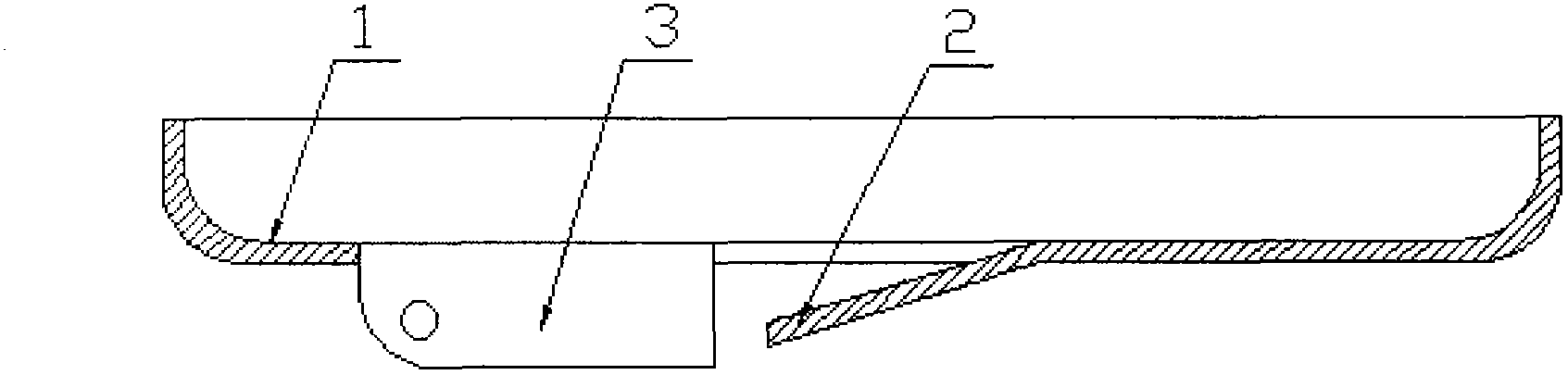

[0011] The base (1) is manufactured by adopting the steel plate cold stamping process, and the square hole (4) is pointed out at the midline of one end of the base (1); at the same time as the square hole is made, the material of the square hole is transformed into a symmetrical shape through the flanging process The two brackets (3) of the bracket (3) are at the midline of the base (1) at one end of the bracket (3), and a part of the material is cut and separated from the base (1) by cold cutting, and the separated part is pressed upward to form a return spring (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com