fume hood

A technology for exhaust hoods and outer covers, applied in the field of exhaust hoods, which can solve problems such as difficult access to connection positions, difficult manufacturing, and complicated manufacturing, and achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

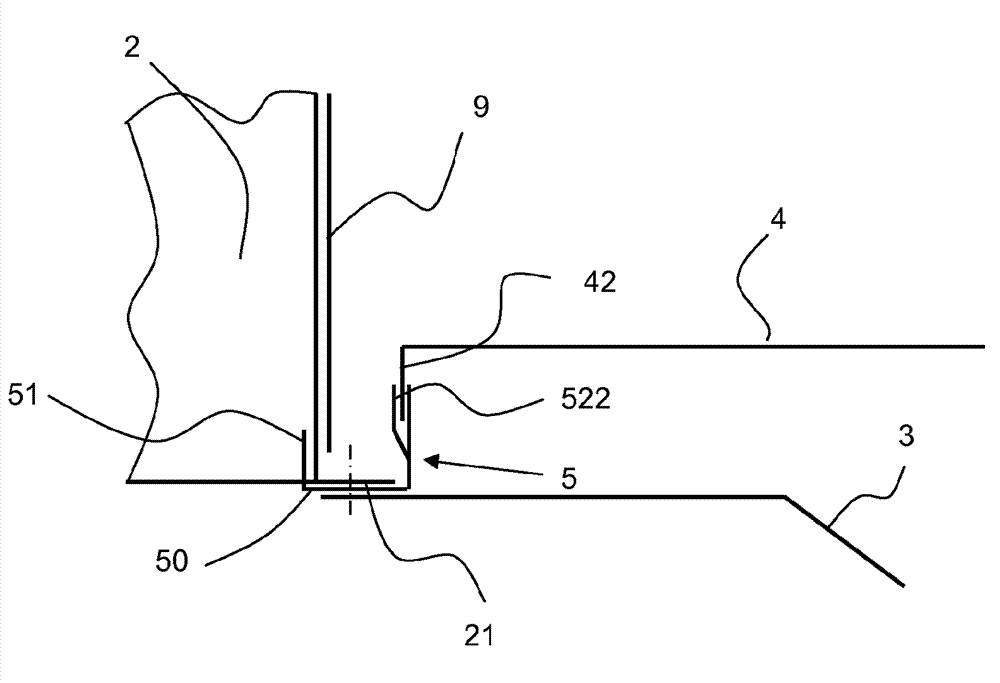

[0040] exist figure 1 The embodiment of the fume extraction hood 1 according to the invention shown in has a ventilation box 2 which comprises a box-shaped base body 20 and which comprises a flange 21 at its bottom side on the side which extends from the base body 20 The sides extend outward respectively. Furthermore, the fume extraction hood 1 has an inner frame 3 which is connected on its upper side to the ventilation box 2 , in particular to a flange 21 . The inner frame 3 has a channel-shaped base body 32 . A rectangular air passage 33 is provided in the bottom of the base body 32 .

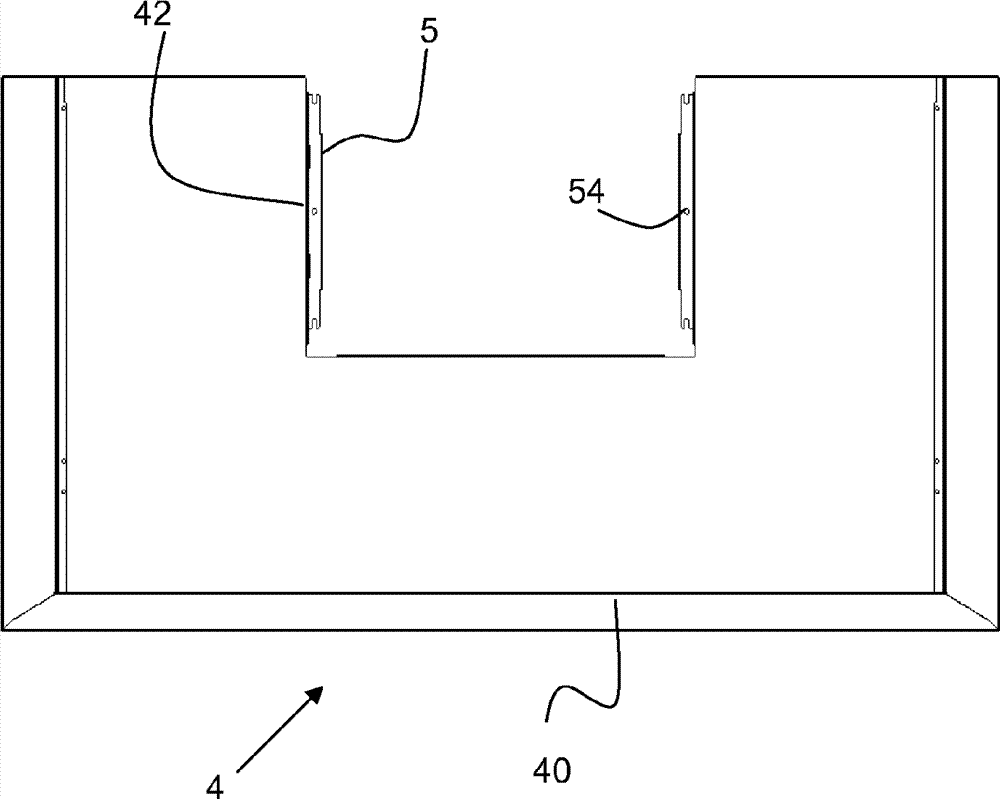

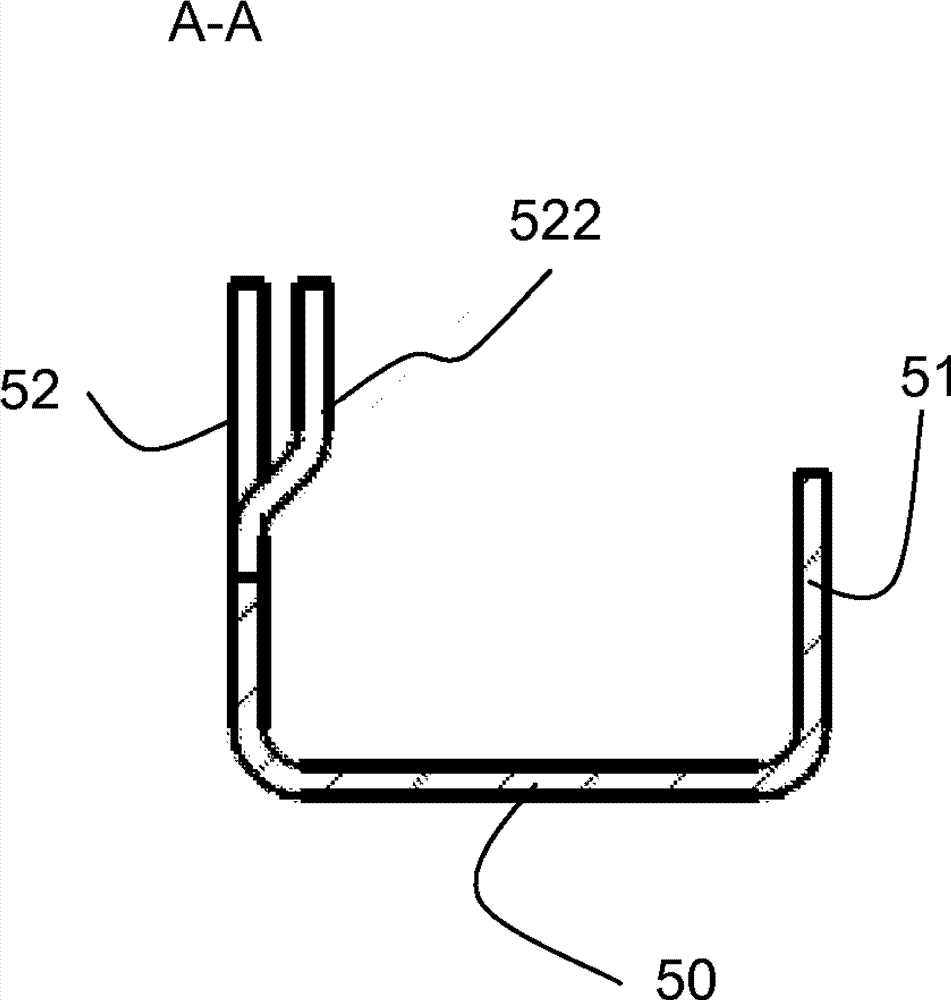

[0041] Furthermore, the fume extraction hood 1 comprises a visible cover 4 which is fixed on a base frame consisting of the ventilation box 2 and the inner frame 3 . On the upper side, the visibility cover 4 has a rectangular recess extending from the rear, the dimensions of which correspond at least to the dimensions of the underside of the ventilation box 2 . On the inner side of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com