Casing conveying device

A conveying device and casing technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., and can solve the problems of difficult transmission of casings and difficult drying process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

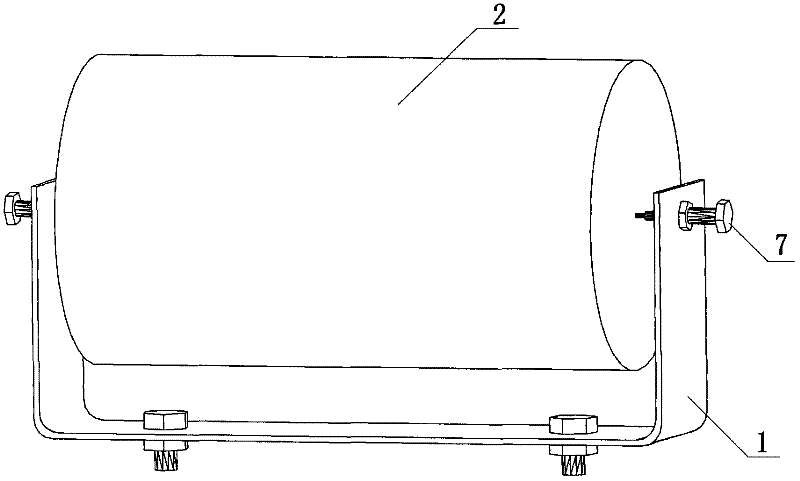

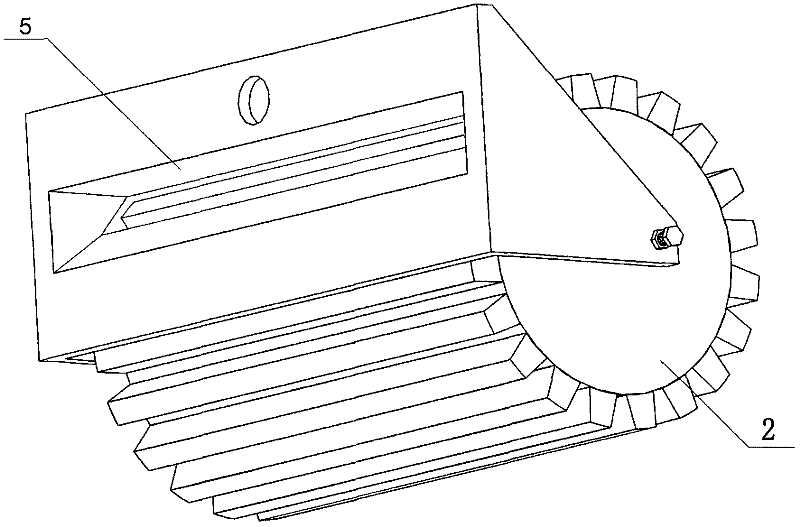

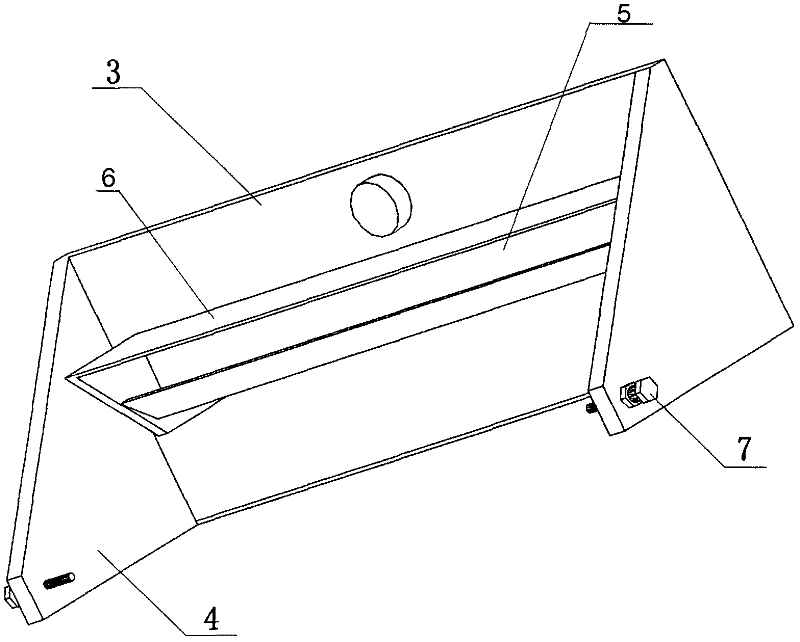

[0026] Such as figure 1 with figure 2 As shown, the present invention provides a casing conveying device, comprising several horizontal conveying units arranged in parallel, the conveying unit comprises a support 1, a roller 2 and an air supply unit (not shown), and the roller 2 is rotatably fixed on the support 1 Above, the surface of the roller 2 is smooth, and may also be provided with grooves or flanges along its width direction. Such as image 3 As shown, the bracket 1 is composed of a base plate 3 and vertical baffles 4 positioned on both sides of the base plate 3, the base plate 3 is provided with a tuyere 5, the tuyere 5 is arranged within the radius of the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com