Method for replacement of bracket brick in chute zone of coke dry quenching furnace

A CDQ coke oven and replacement method technology, which is applied in the coking field, can solve problems such as the aggravation of cold and heat shrinkage, achieve the effects of prolonging the service life, improving the integrity and structural safety and reliability, and slowing down the damage speed

Inactive Publication Date: 2012-06-13

PANGANG GRP ENG TECH

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] Aiming at the problem that the corbel bricks in the chute area are broken and peeled off due to repeated heating and cooling of the refractory material, the corbel bricks are broken and peeled off. The CDQ coke oven includes an upper cone, a pre-storage chamber, an annular air duct surrounding the pre-storage chamber and communicating with the pre-storage chamber, a middle bolt hole, an inclined air duct, and a cooling chamber. The upper annular air duct and the lower cooling chamber pass through the middle incli

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

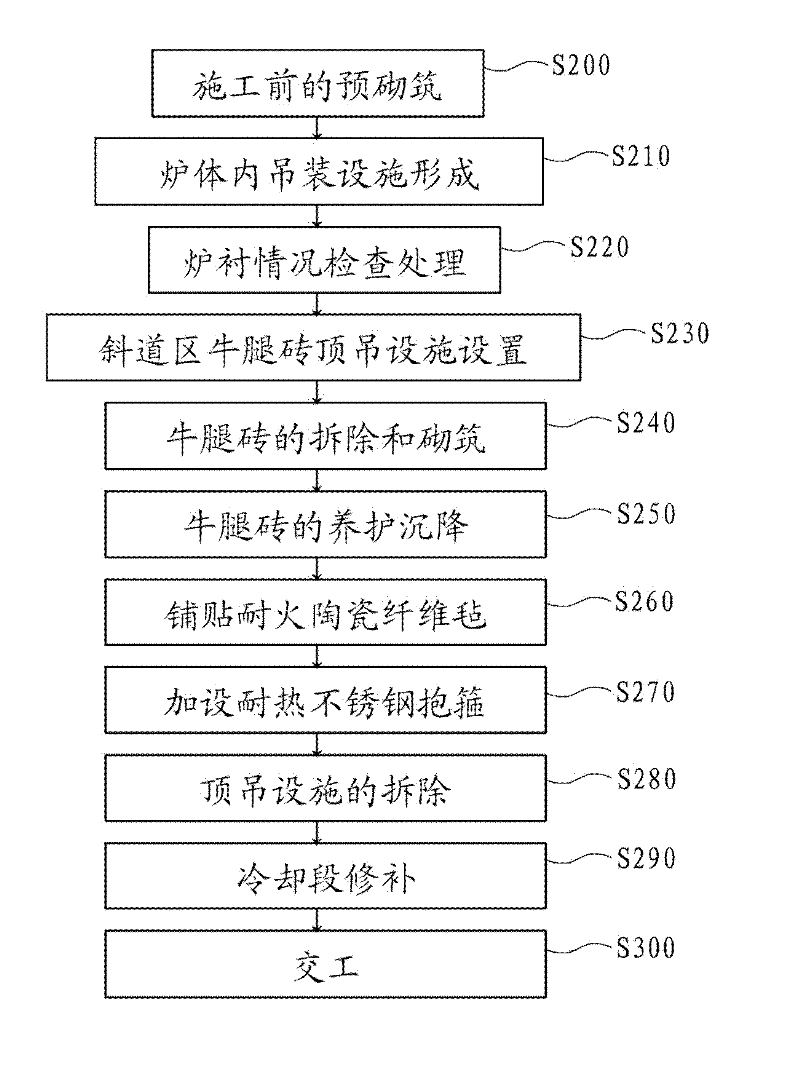

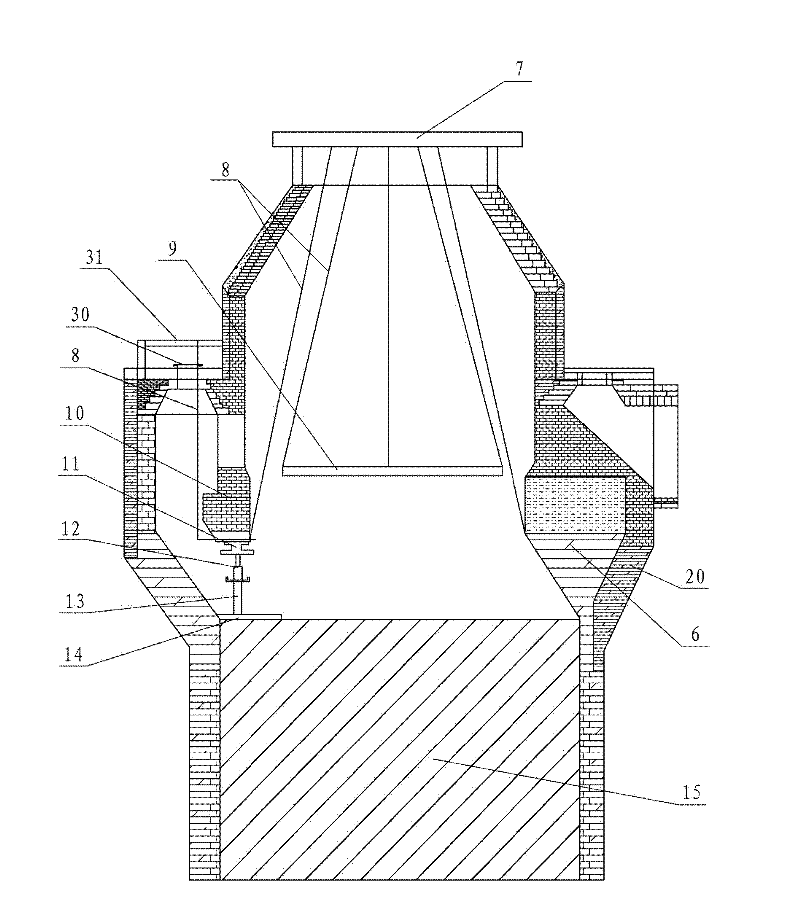

The invention provides a method for replacement of a bracket brick in a chute zone of a coke dry quenching furnace. The coke dry quenching furnace comprises an upper cone, a pre-storage chamber, an annular air flue which is arranged around the pre-storage chamber and is communicated with the pre-storage chamber, a middle bolt aperture, an inclined air flue and a cooling chamber. The annular air flue arranged at an upper part of the coke dry quenching furnace is communicated with the cooling chamber arranged at a lower part of the coke dry quenching furnace by a chute zone. The chute zone comprises bracket bricks uniformly distributed along the periphery of the coke dry quenching furnace. The bracket bricks are utilized for supporting the upper part of the coke dry quenching furnace and divide the chute zone into multiple independent chutes. The method provided by the invention comprises the following steps of 1, dismounting a damaged bracket brick and building a novel bracket brick, and 2, paving a fire-resistant material layer on the surface of the novel bracket brick and arranged a protective cover outside the fire-resistant material layer. The method can effectively protect bracket bricks in the chute zone of the coke dry quenching furnace, delays a bracket brick damage speed, and prolongs a bracket brick service life thereby prolonging a maintenance period and a replacement period of a bracket brick in the chute zone.

Description

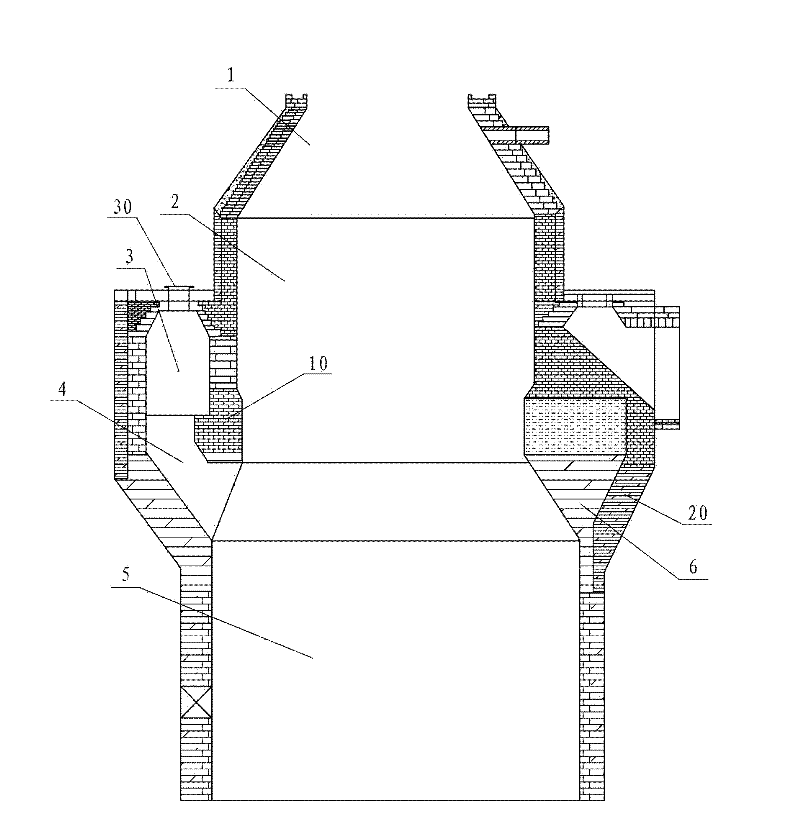

technical field [0001] The invention relates to the technical field of coking, in particular to a method for replacing the corbel bricks in the CDQ coke oven chute area, the method can strengthen the protection of the CDQ coke oven chute area corbel bricks and prolong the CDQ coke oven chute The service life of the corbel brick in the area. Background technique [0002] Coke quenching is an important link in the coke production process. As an important project for energy saving and emission reduction in the coking process, CDQ has been widely used in China. With the popularization and application of domestic large-scale CDQ, the development of CDQ technology and Research has gradually become a hot topic in the industry. [0003] The CDQ oven is the main component of the CDQ device. figure 1 A schematic diagram of the structure of the dry quenching coke oven is shown in , such as figure 1 As shown in , the CDQ coke oven mainly includes an upper cone 1, a pre-storage room 2...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10B39/02

Inventor 蒋辉秦川吴荣善冯树雄何天均肖磊彭将国

Owner PANGANG GRP ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com