Nickel-chromium plating part and manufacturing method thereof

A manufacturing method and component technology, applied in nickel-chrome-plated components and its manufacturing field, can solve problems such as poor corrosion resistance, corrosion resistance that cannot meet the requirements of corrosive environments, and unsuitable products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

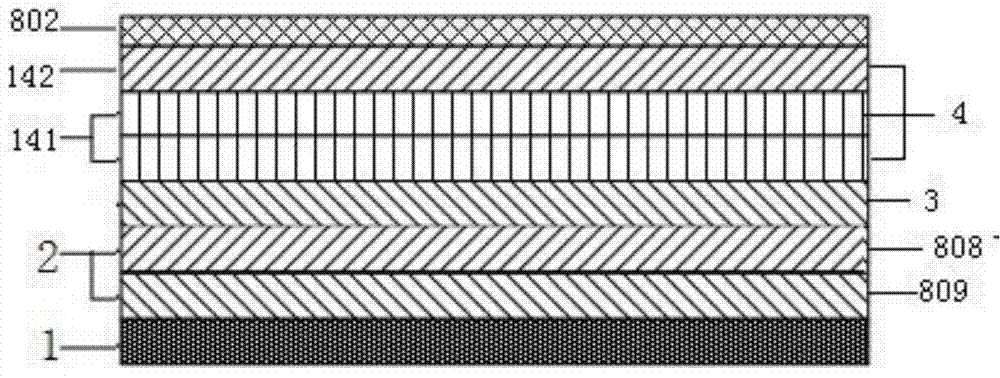

[0080] The nickel-chromium plating part of the present embodiment, this part comprises: base material 1 (ABS material); Pretreatment plating layer 2 comprises chemical nickel layer 809, makes a bottom nickel layer 808 and copper-plated layer 3, and chemical nickel layer deposits 809 to deposit on On the whole substrate 1, a bottoming nickel layer 808 is deposited on the chemical nickel layer 809, and a copper plating layer 3 is formed on the bottoming nickel layer 808; and a functional layer 4, which is formed on the copper plating layer 3, wherein the functional layer 4 comprising a low-potential nickel layer 141 and a microporous nickel layer 142, wherein the low-potential nickel layer 141 is a high-sulfur nickel layer, the microporous nickel layer 142 formed on the high-sulfur nickel layer; and the microporous nickel layer 142 formed on the microporous nickel layer 142 Decorative layer 802 (trivalent white chrome plating).

Embodiment 2

[0082] The nickel-chromium plating part of the present embodiment, this part comprises: base material 1 (ABS material); Pretreatment plating layer 2 comprises chemical nickel layer 809, makes a bottom nickel layer 808 and copper-plated layer 3, and chemical nickel layer deposits 809 to deposit on On the whole substrate 1, a bottoming nickel layer 808 is deposited on the chemical nickel layer 809, and a copper plating layer 3 is formed on the bottoming nickel layer 808; and a functional layer 4, which is formed on the copper plating layer 3, wherein the functional layer 4 comprising a low-potential nickel layer 141 and a microporous nickel layer 142, wherein the low-potential nickel layer 141 is a microcracked nickel layer, the microporous nickel layer 142 formed on the microcracked nickel layer; and the microporous nickel layer 142 formed on the microporous nickel layer 142 Decorative layer 802 (trivalent black chrome plating).

Embodiment 3

[0084] The nickel-chromium plating part of the present embodiment, this part comprises: base material 1 (ABS material); Pretreatment plating layer 2 comprises chemical nickel layer 809, makes a bottom nickel layer 808 and copper-plated layer 3, and chemical nickel layer deposits 809 to deposit on On the whole substrate 1, a bottoming nickel layer 808 is deposited on the chemical nickel layer 809, and a copper plating layer 3 is formed on the bottoming nickel layer 808; and a functional layer 4, which is formed on the copper plating layer 3, wherein the functional layer 4 includes a low-potential nickel layer 141 and a microporous nickel layer 142, wherein the low-potential nickel layer 141 is a high-sulfur nickel layer and a micro-crack nickel layer (it may be that the high-sulfur nickel layer is formed on the copper plating layer 3, and the micro-crack nickel layer is formed On the high-sulfur nickel layer; it can also be that the micro-crack nickel layer is formed on the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com