Jacking system for buildings

A building and jacking technology, applied in building construction, construction, building maintenance, etc., can solve the problems of increased cost, long operation time, endangering engineering safety, etc., to prevent overall instability, improve safety factor, and enhance safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

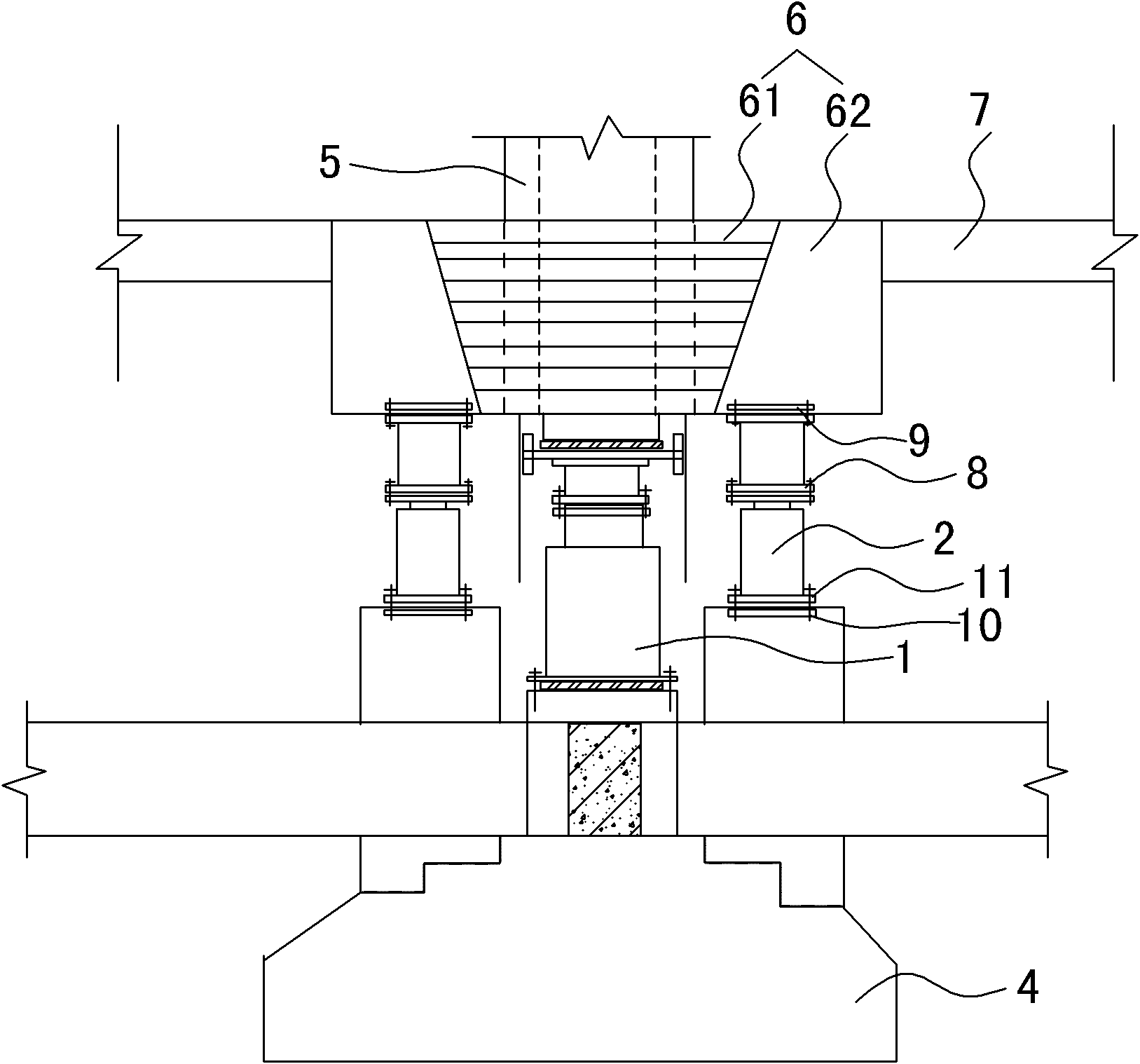

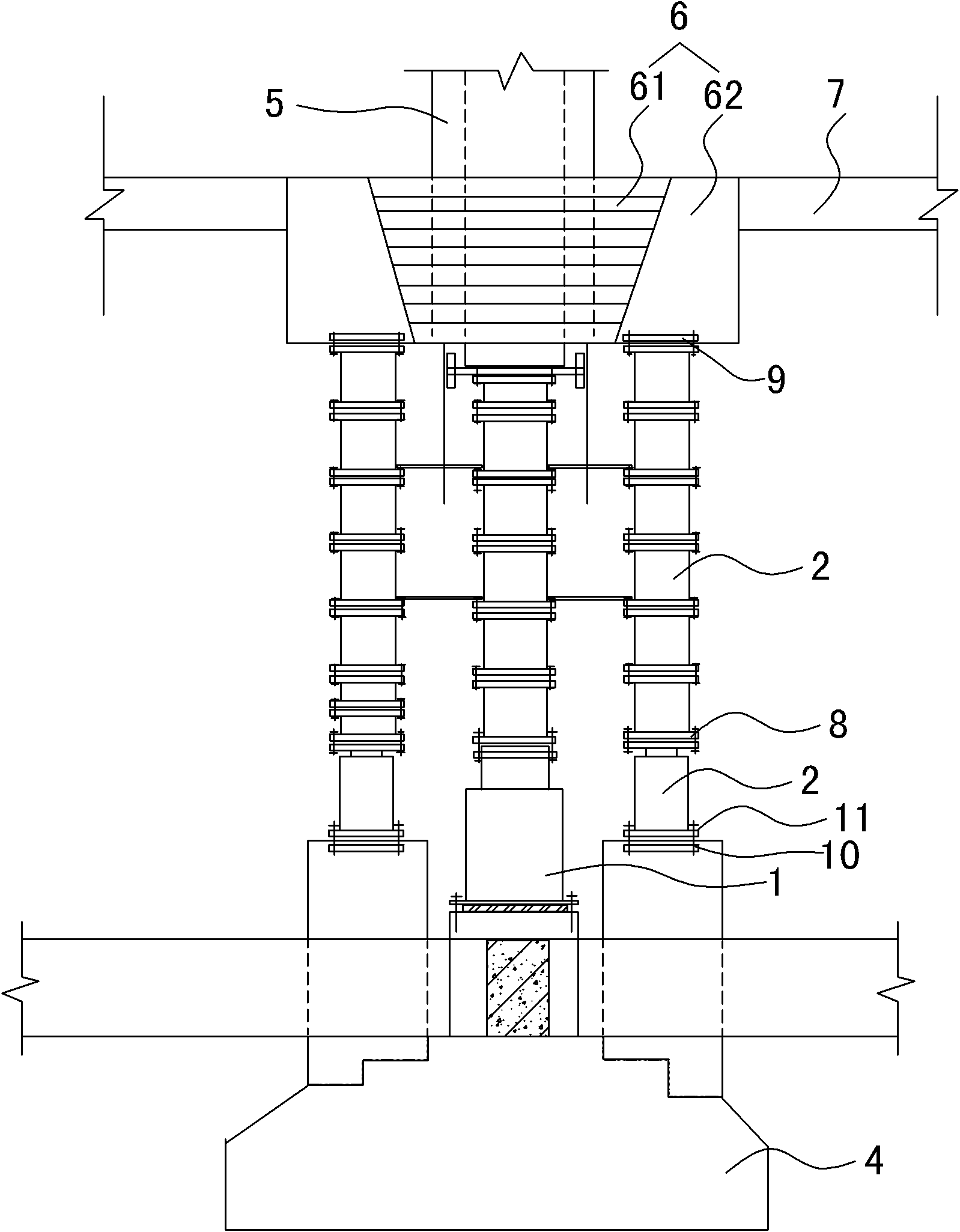

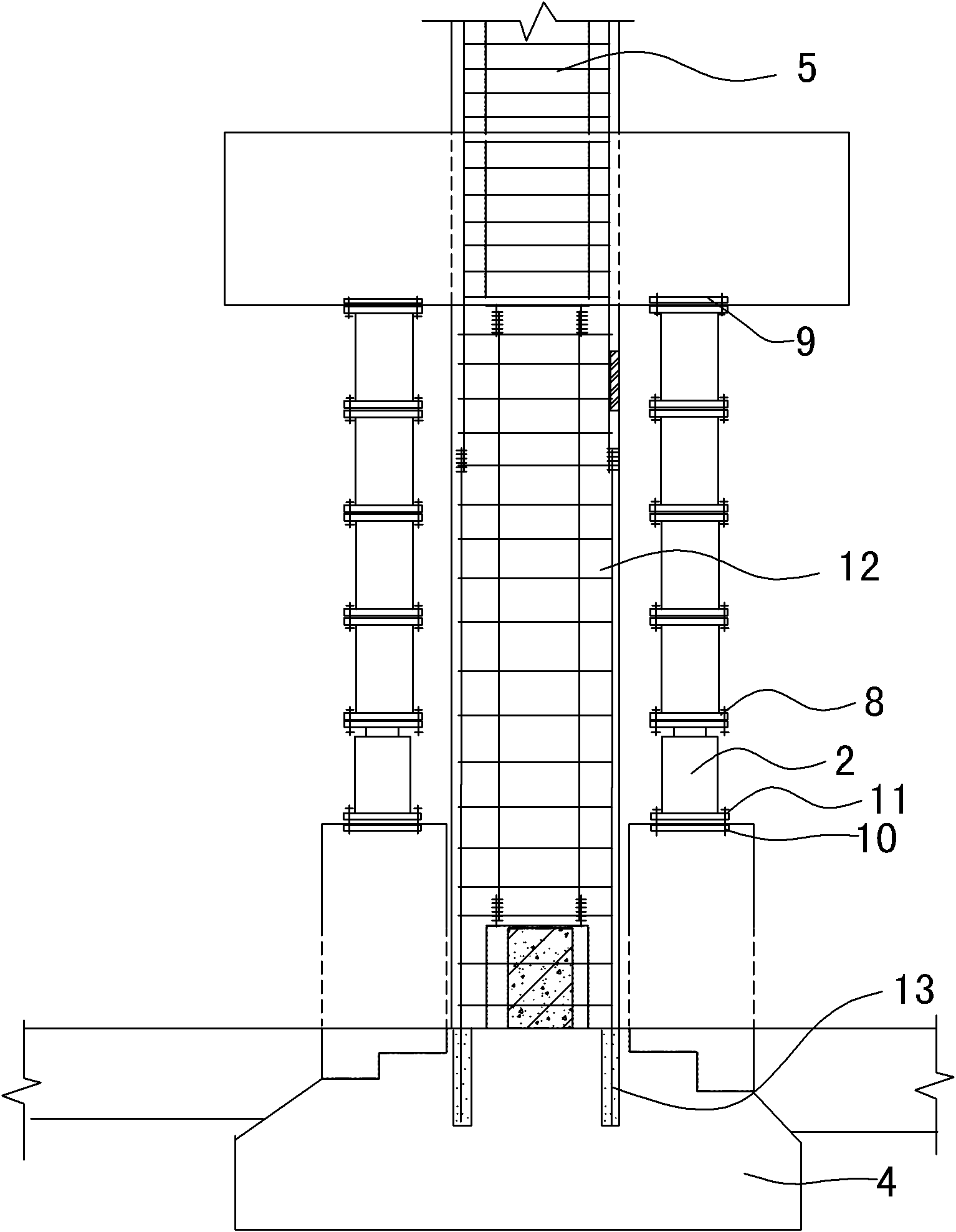

[0028] Such as figure 1 As shown, the building jacking system of the present invention includes at least one main jack 1, at least two first pads 2 and a plurality of second pads 3, the main jack 1 and the first pads 2 They are all placed on the foundation 4 at the bottom of the building, and the two sides of the main jack 1 are respectively provided with a first pad 2, and a plurality of second pads 3 are fixed on the main jack 1 and the building. between objects, and between the first pad 2 and the building; wherein, the length of the first pad 2 is adjustable, and in this preferred embodiment, the first pad 2 is threaded jack.

[0029] When starting to lift, first carry out jacking by the main jack 1; when the main jack 1 lifts the building to a certain stroke (generally the maximum stroke that the main jack 1 lifts each time), the The main jack 1 stops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com