Method for machining bottom R of reverse taper end milling cutter

A processing method and end mill technology, which is applied in the processing field of reverse taper end mill midsole R, can solve problems such as hidden dangers in the finishing process, changes in the internal organization of the tool, and failure to meet production needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

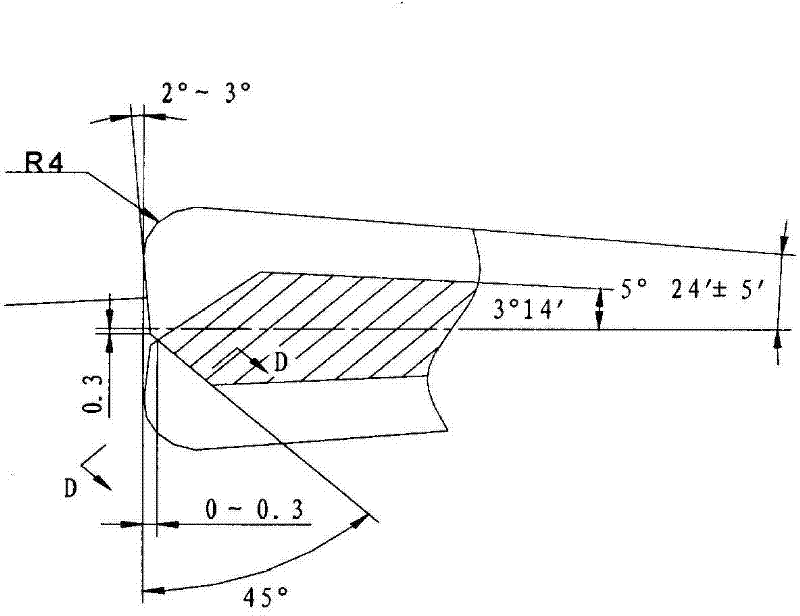

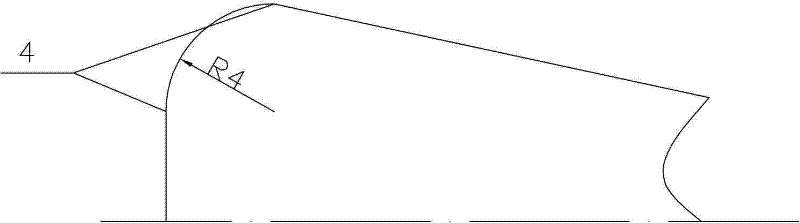

[0017] Such as figure 1 As shown, a method for processing the bottom R of a reverse taper end mill, wherein R=4mm, is characterized in that it comprises the following steps:

[0018] 1) Raw material preparation: According to the drawing requirements of the reverse taper end mill, there is a margin for the width and length of the milling cutter. Its overall shape is a cylinder at the front end and a cone at the back end;

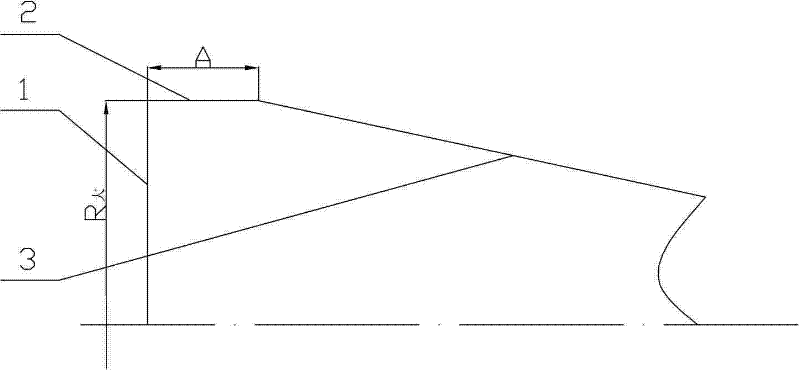

[0019] 2) if figure 2 As shown, roughing:

[0020] 2.1) Clamp with the top, turn the front end face, and see the light, so that the end face becomes the reference plane;

[0021] 2.2) Use the grinding method to grind the cylinder at the front end so that the outer circle is directly the diameter R of the large end 大 ;

[0022] 2.3) Grinding the tapered surface at the rear end until the length of the cylinder is A, where A=the value of the radius of the bottom R, that is, A=4mm;

[0023] 3) Cut the forming grinding wheel with a template of the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com