Ceramic glaze modifying additive and preparation method and application thereof

A technology of ceramic glazes and additives, applied in the field of ceramics, can solve problems such as instability, fluorine organic coatings are easy to scratch, lose non-stick function, etc., and achieve the effect of no decomposition and damage, smooth glaze surface, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

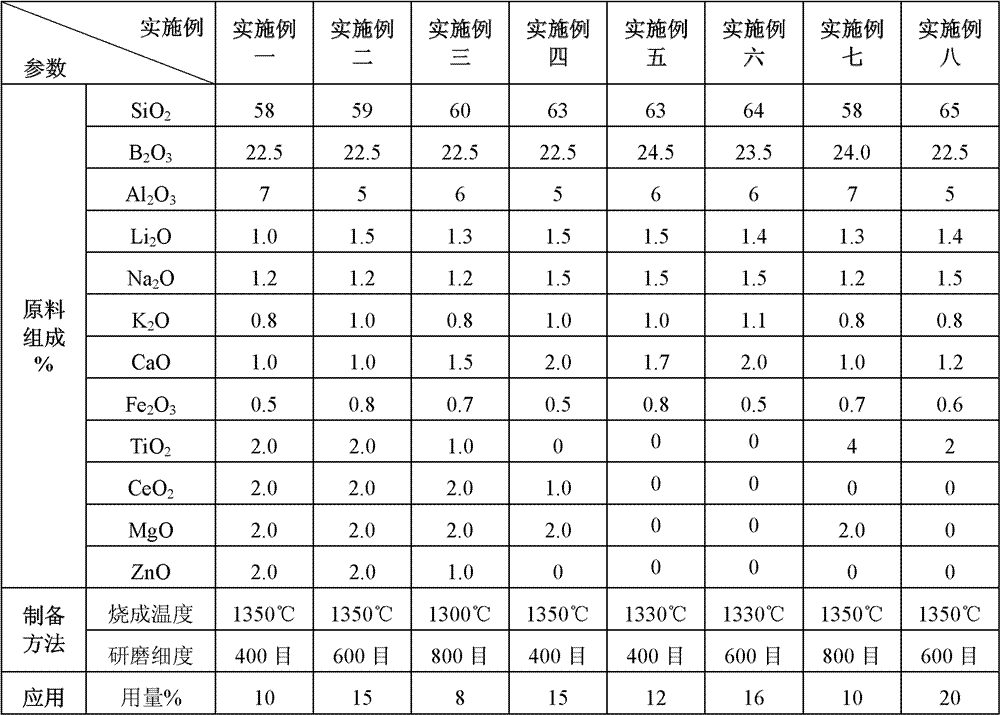

[0016] The ceramic glaze modification additive of the embodiment of the present invention, its raw material composition by weight percentage is: SiO 2 58-65%, B 2 o 3 22.5~24.5%, Al 2 o 3 5.0~7.0%, Li 2 O 1.0~1.5%, Na 2 O 1.2~1.5%, K 2 O0.8~1.2%, CaO 1.0~2.0%, Fe 2 o 3 0.5~0.8%, TiO 2 0~5.0%, CeO 2 0-4.0%, MgO 0-5.0%, ZnO 0-4.0%.

[0017] The preparation method of the ceramic glaze modification additive in the embodiment of the present invention is as follows: the above-mentioned raw materials are mixed by ball milling, dehydrated and dried, fired at a temperature of 1300-1350 °C, and then pulverized and ground into a powder of 400-800 mesh to obtain a ceramic glaze Material modification additive products.

[0018] The application of the ceramic glaze modified additive product in the embodiment of the present invention is as follows: add to ceramic glaze, especially the glaze used for low-expansion ceramic cookware, and its consumption is 8-20% of the ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com