Ball head pin locking device

A technology of locking device and ball stud, which is applied in the direction of pivot connection, etc., can solve the problems of complex structure, poor stress condition, easy loosening, etc., and achieve the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

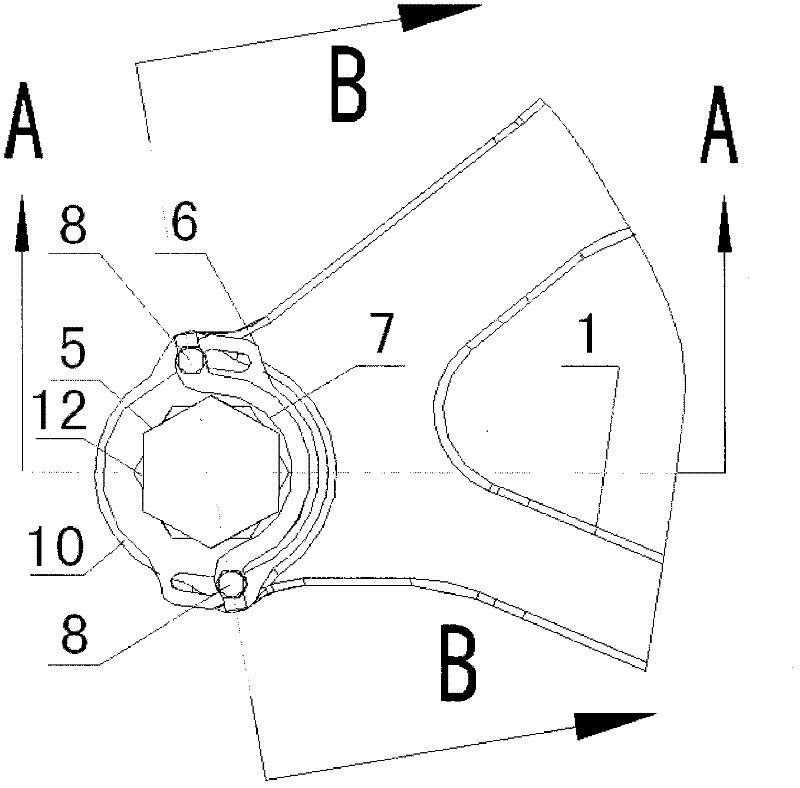

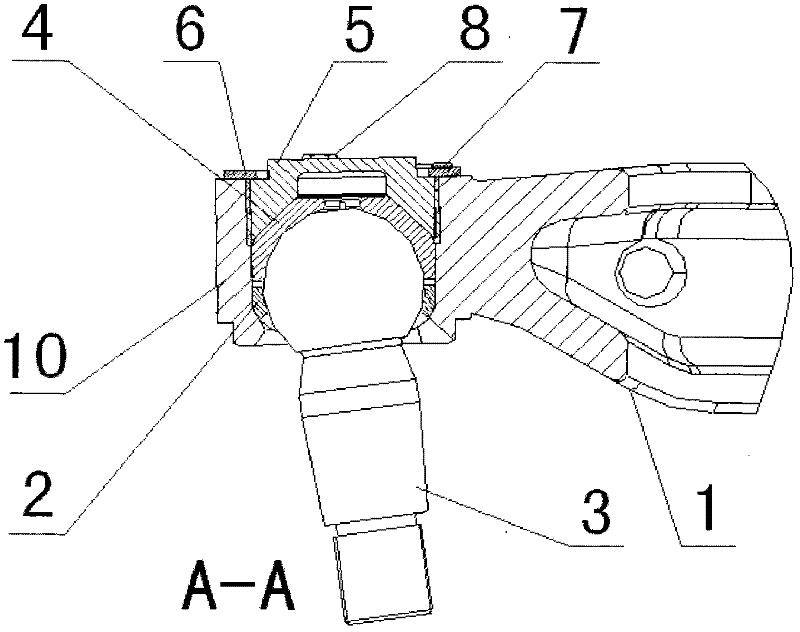

[0040] The ball stud locking device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0041] 1. Basic composition

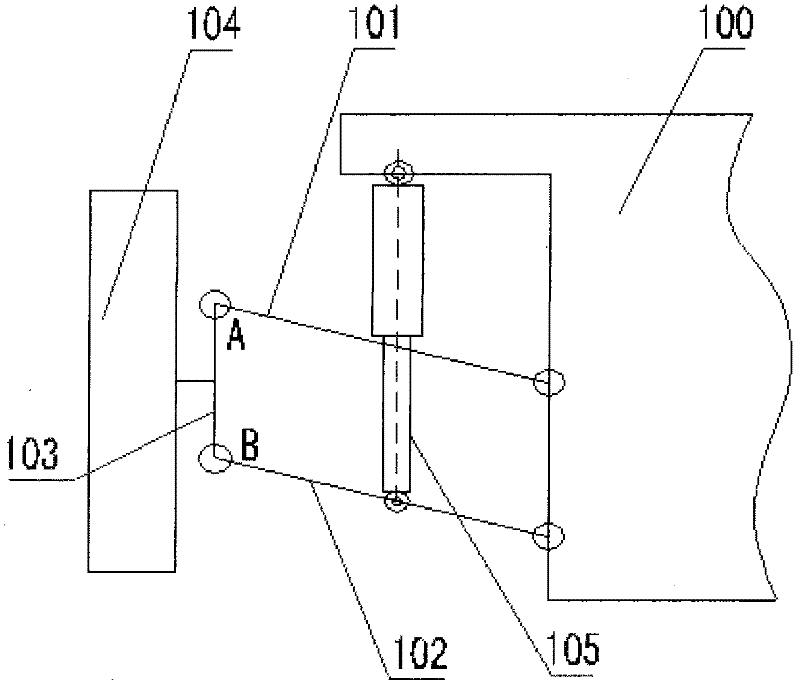

[0042] Such as Figure 2-Figure 4 As shown, the ball stud locking device of the present invention includes being installed on the cross arm 1 (this cross arm can be figure 1 The ball seat 10, the lower ball bowl 2, the ball stud pin 3, the upper ball bowl 4, the ball bowl gland 5, the locking gasket 6, Arch washer 7 and locking screw 8.

[0043] The upper ball bowl 4 and the lower ball bowl 2 are all placed in the ball head seat 10. After the upper and lower ball bowls are fastened together, the ball head of the ball stud pin 3 is clamped. The radial direction of the ball head is close to the ball head seat 10. Constraint; the lower outer spherical surface of the ball head is supported by the tapered surface at the bottom of the inner surface of the ball head seat, forming a constraint on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com