Plate drilling machine

A drilling machine and plate technology, applied in the field of mechanical processing, can solve the problems of low processing efficiency and high cost of forming holes, and achieve the effect of reducing processing cost and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

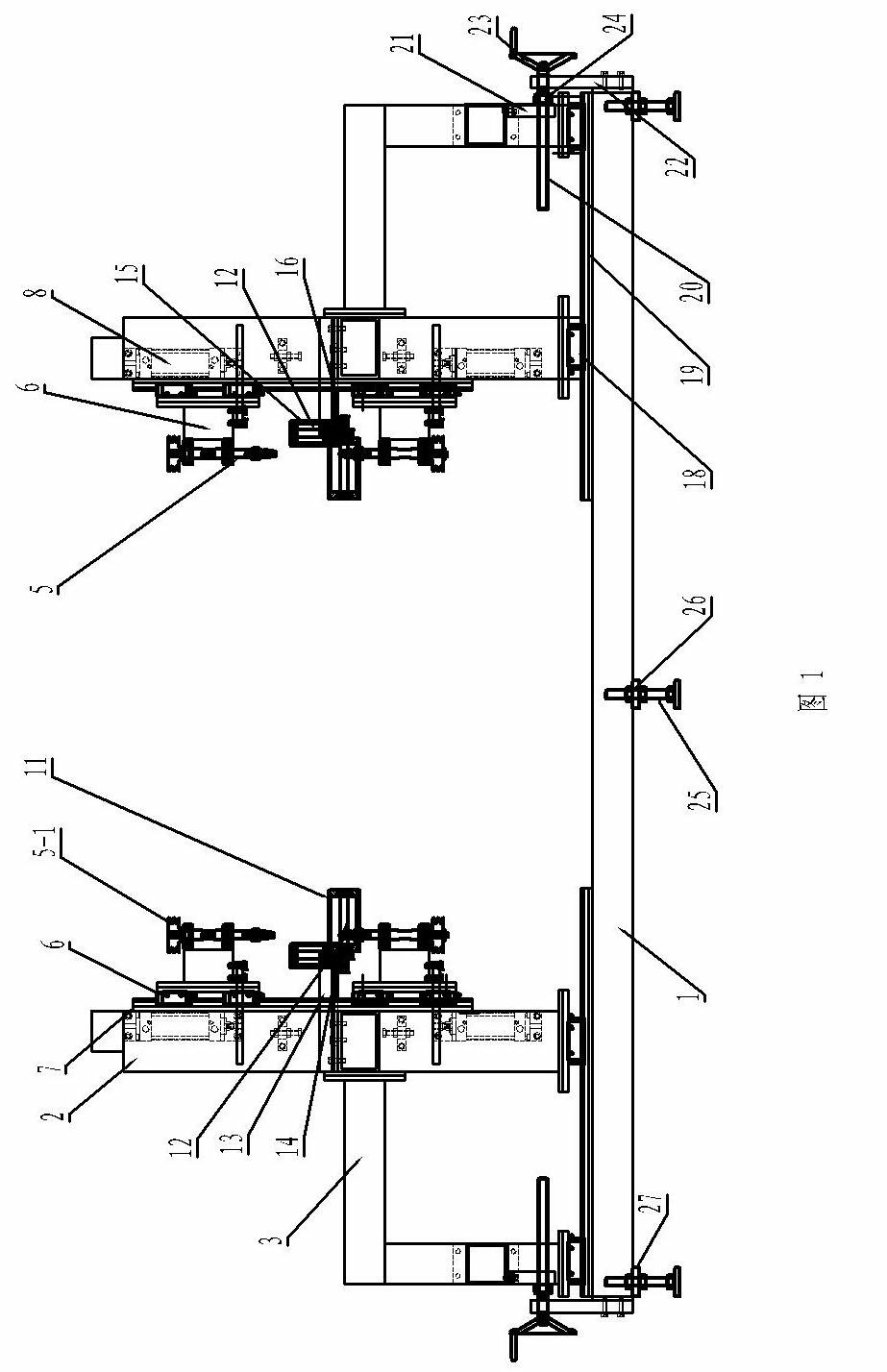

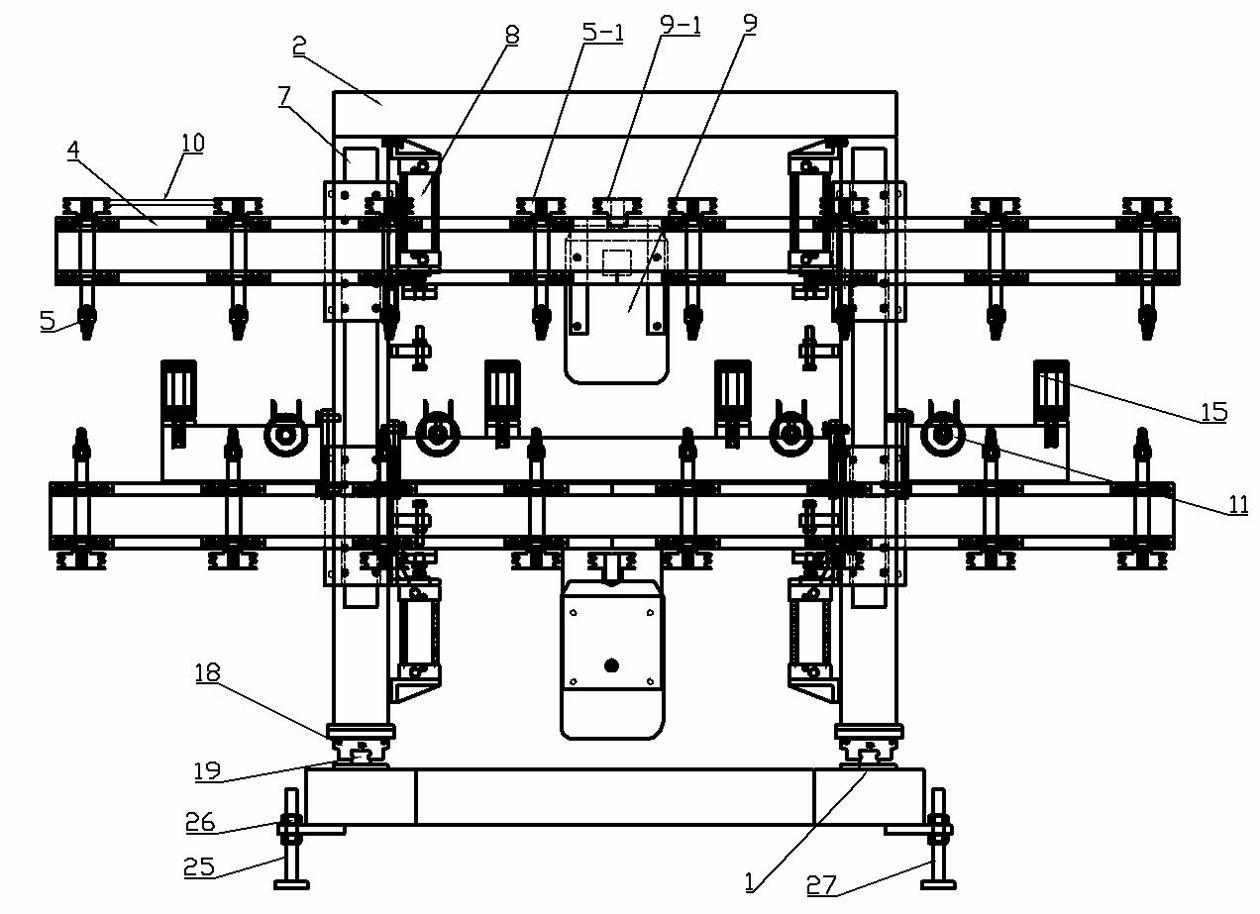

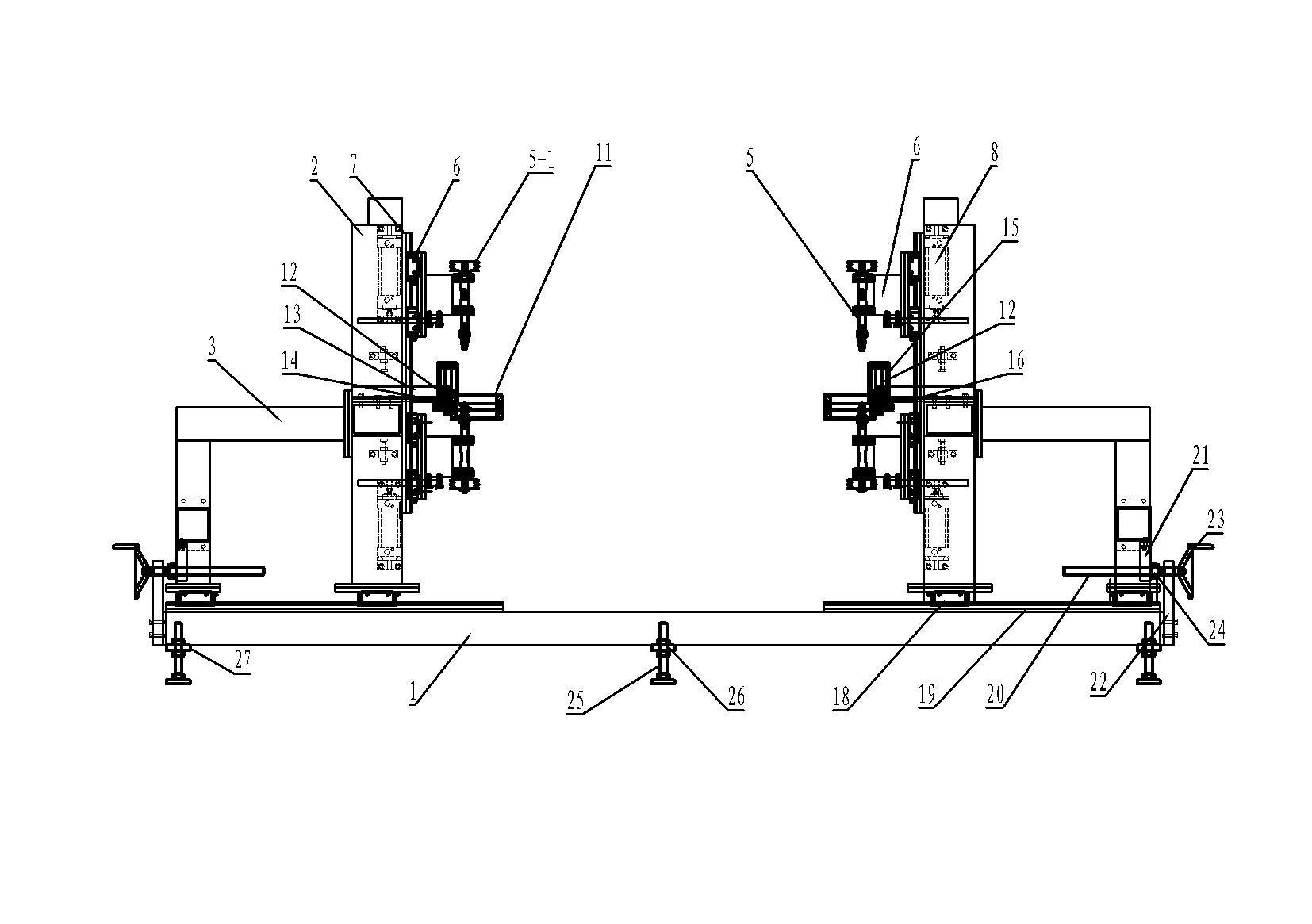

[0019] The embodiment of plate drilling machine of the present invention: as figure 1 and figure 2 As shown, the drilling machine is mainly composed of a base 1, a vertical support, a bracket 4 and a drilling mechanism arranged on the bracket, wherein the drilling mechanism is mainly due to the vertical drill bits 5 arranged side by side at vertical intervals on the bracket 4 , a clamping cylinder 8, and a motor 9; there are two vertical supports, which are respectively located at opposite ends of the base 1, and the two vertical supports are arranged symmetrically. 2 is composed of an inverted L-shaped positioning bracket 3 arranged on one side close to the corresponding edge of the base 1, wherein the two gantry frames 1 are provided with two parallel brackets 4 on the opposite sides, and the brackets 4. The slide block 6 arranged on the side close to the gantry 2 is guided and matched with the vertical guide rails 7 correspondingly arranged on the two columns of the gantr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap