Waste tire rescue cage combination embankment

A technology for waste tires and tires, which is used in dikes, coastline protection, dams, etc., to achieve the effects of fast processing speed, fast and flexible assembly and disassembly, and high self-supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

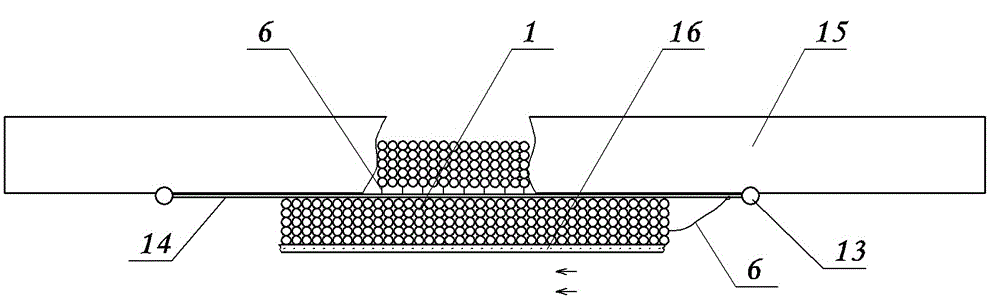

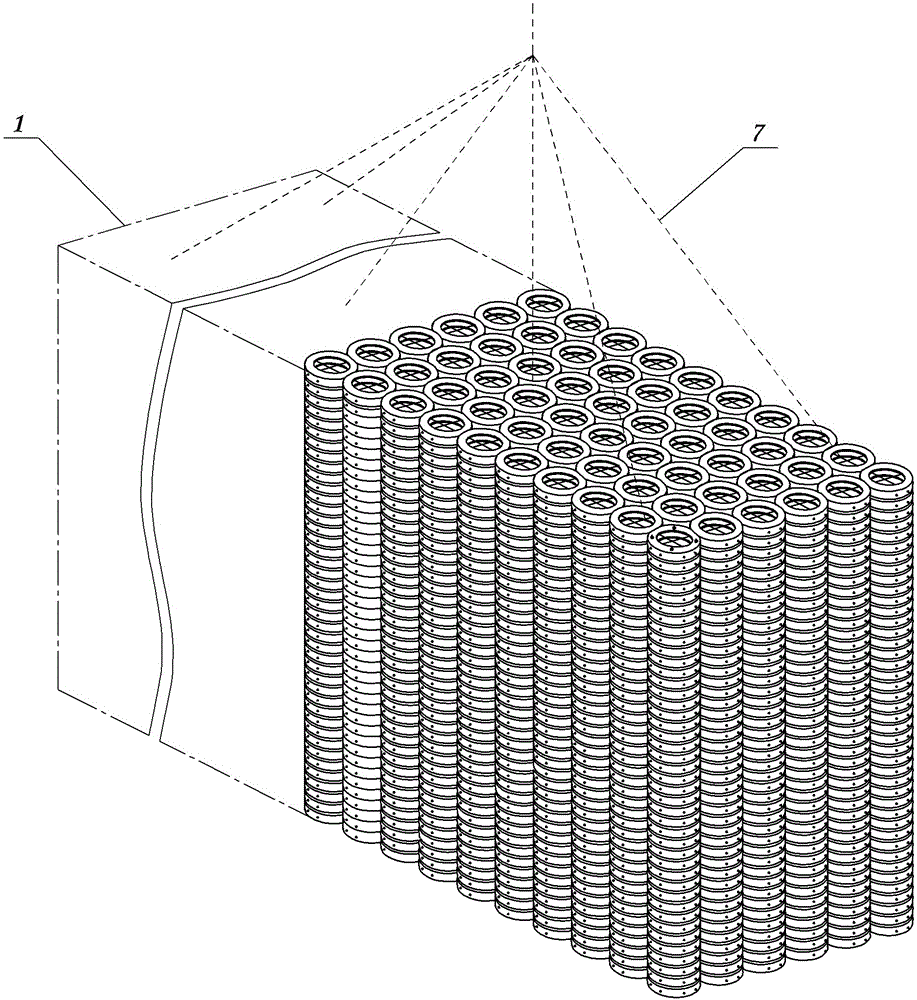

[0027] Embodiment one: see figure 1 , figure 2 , image 3 with Figure 4 , the waste tire rescue cage 1 is a waste tire prestressed block composed of multiple layers of the waste tire prestressed mesh, and a fixed hook for lifting and connecting with other waste tire prestressed blocks is arranged above the prestressed block 6. Each waste tire prestressing mesh is composed of a plurality of waste tire prestressing belts.

[0028] See the specific structure figure 2 with image 3 :

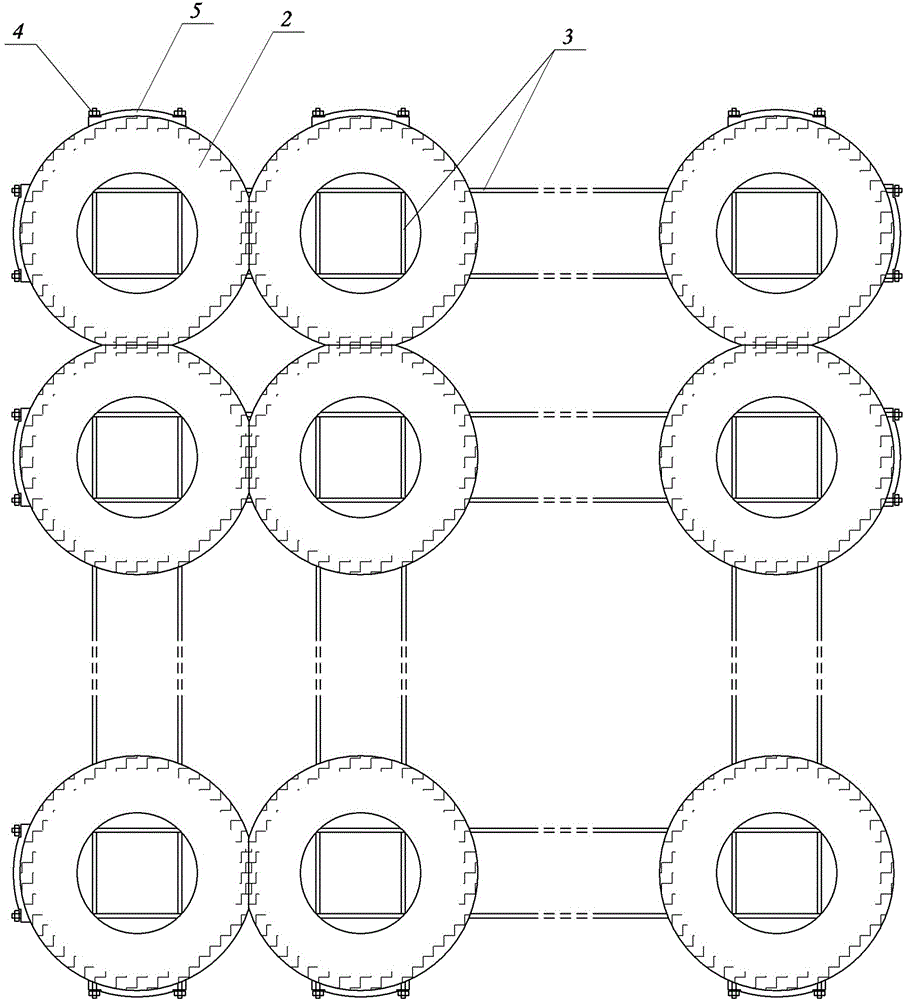

[0029] The waste tire prestressing belt is a belt structure formed by a plurality of waste tires 2 being sequentially butted horizontally, and a parallel steel strand 3 is inserted into each waste tire, and the two ends of the steel strand 3 are respectively anchored after prestressing On the outer edges of the outermost tires at both ends, side gaskets 5 are provided.

[0030] The waste tire prestressed mesh is a network structure formed by butt jointing of a plurality of waste tire pres...

Embodiment 2

[0033] Embodiment two: accompanying drawing is not drawn, and content is basically the same as embodiment one, and similarity is not repeated, and difference is: fill concrete, or fill stone and rubbish etc. in the waste tire rescue cage after fixing .

Embodiment 3

[0034] Embodiment three: accompanying drawing is not drawn, and content is basically the same as embodiment one, and similarity is not repeated, and difference is: the two ends of described steel strand 3 are respectively fixed with bolt 4, and bolt cooperates with nut to make steel strand The wire is fixed to the side spacer 5 on the outer edge of the outermost tire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com