Bamboo-like truss structure

A truss structure, imitating bamboo technology, applied in the direction of truss structure, truss beams, joists, etc., can solve the problems of assembly difficulty, affect the bending stiffness and strength of the structure, and form a smooth surface, so as to improve the stiffness and strength, strengthen the Effects of bending and radial compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

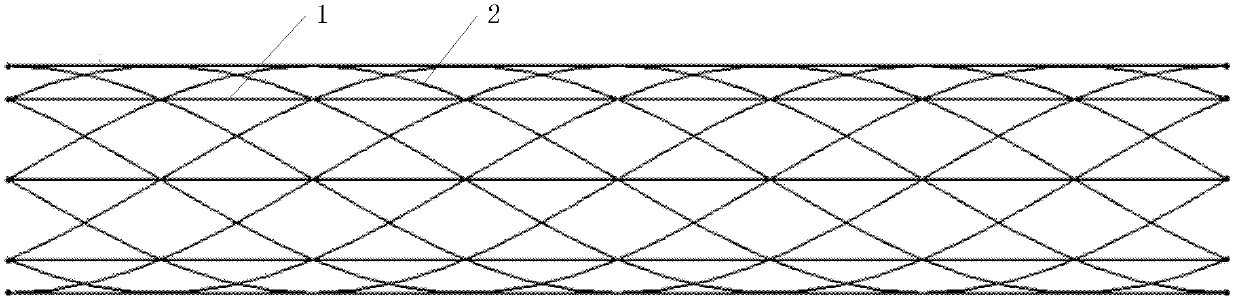

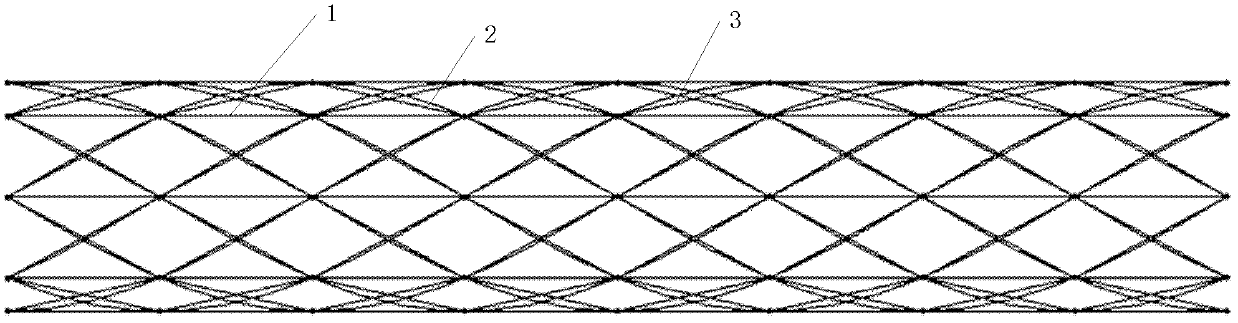

[0033] This embodiment is a bamboo imitation truss structure, which consists of a cylindrical bus bar unit 1 , a cylindrical spiral curved bar unit 2 , a spiral broken line bar unit 3 and a radial bar unit 4 .

[0034] The rod unit along the axial direction of the imitation bamboo truss structure is composed of a cylindrical generatrix rod unit 1, a cylindrical spiral curve rod unit 2 and a spiral broken line rod unit 3, and the radial rod unit 4 is connected by a straight line segment to the spiral curve rod in the same cross section The intersection of the element with the bus bar element is formed.

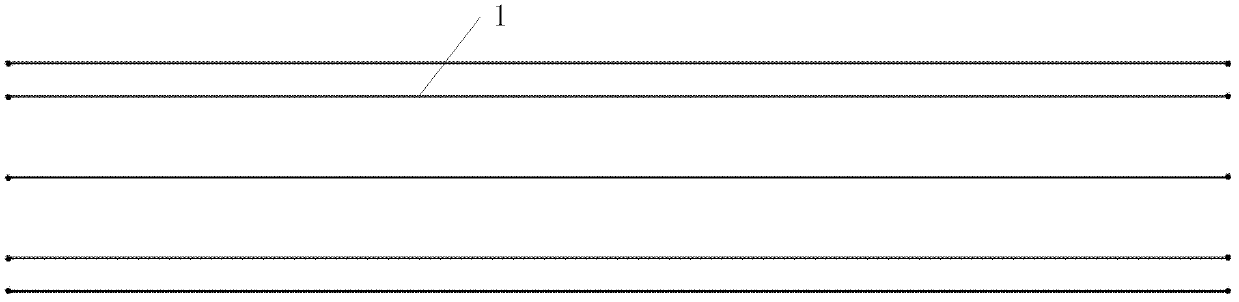

[0035] Cylindrical bus bar units 1 are evenly distributed on the cylindrical surface along the circumferential direction of the cylindrical surface, and the number of cylindrical bus bar unit segments is set to n, then n≥3.

[0036] The cylindrical spiral curved rod unit 2 is formed by spirally winding clockwise and counterclockwise along the cylindrical surface starting from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com