Vehicle body structure and railway vehicle

A car body structure and car roof technology, which is applied to the railway roof and other directions, can solve the problems of inability to install high-arc roofs at the same time, lower car body rigidity, poor structural continuity, etc., and achieve the effect of maintaining lightweight, less welding, and less stress. evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

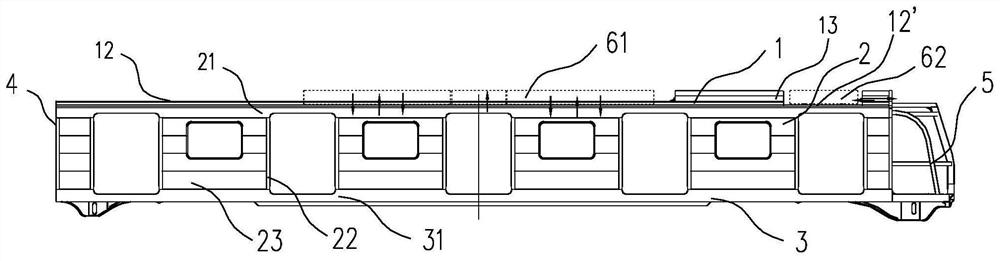

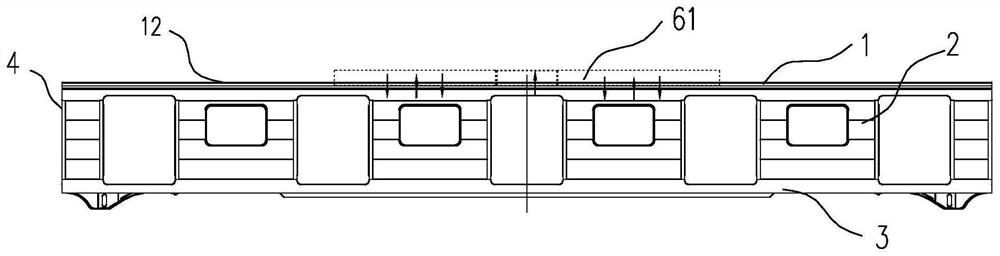

[0039] Rail vehicle body structure such as figure 1 Schematic diagram of the head car body structure, figure 2 As shown in the structural diagram of the intermediate car body, the car body mainly includes a roof 1, a side wall 2, an underframe 3, an end wall 4 and a driver's cab frame 5, wherein the intermediate car does not include the driver's cab frame 5. figure 1 The roof 1 in the vehicle comprises a low arc roof 12 and a high arc roof 13 at the front section of the roof. The side wall 2 adopts an integral structure, including a roof side rail 21 with a long upper part, a door pillar 22 and a side wall panel 23 . On the roof 1, the main installed equipment is a passenger room air conditioner unit 61.

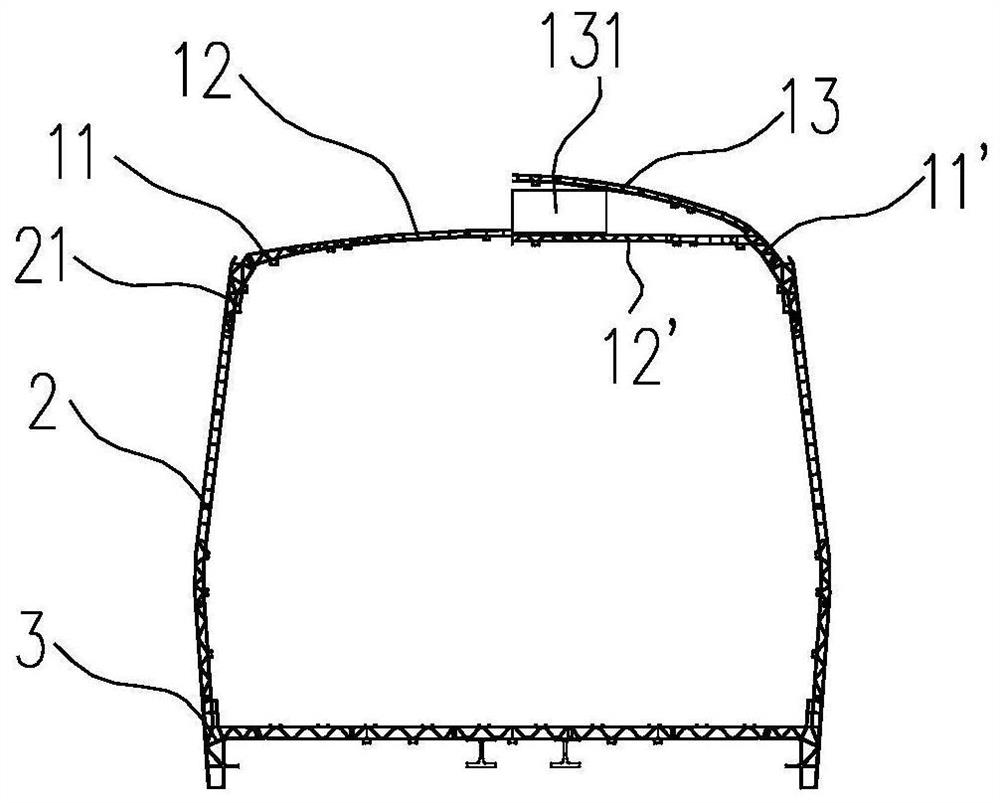

[0040] Figure 3-6 It is a schematic cross-sectional view of a car body, mainly including a roof 1 , a side wall 2 , and an underframe 3 . The car bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com