Assembly installation and dynamic adjustment device for sensor for comprehensive logging

A combined installation and comprehensive mud logging technology, applied in the field of oil and gas exploration, can solve the problems that affect the quality of work, the sensor cannot be removed, and is not suitable for the scientific and standardized requirements of comprehensive mud logging sensors, so as to reduce the labor intensity of personnel and ensure safe and reliable operation , Realize the effect of oil and gas exploration benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

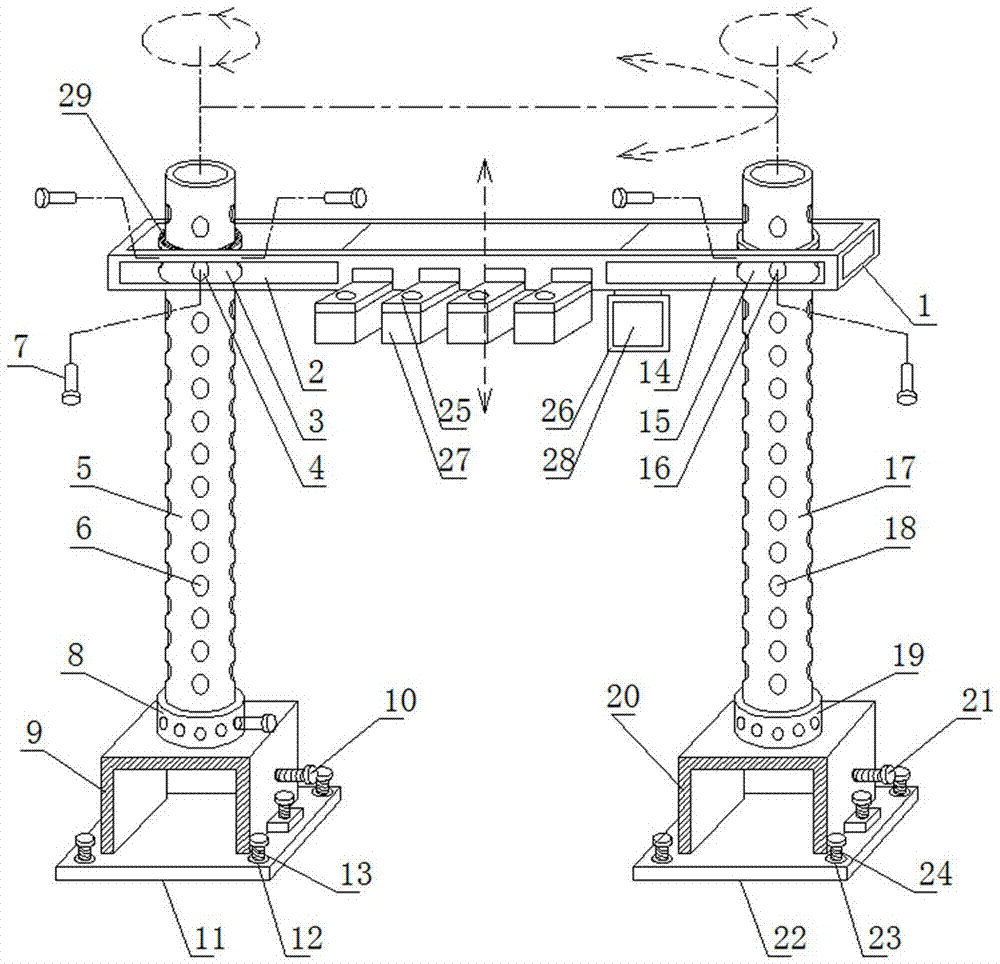

[0056] The combined installation and adjustment device of the comprehensive mud logging sensor of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0057] As shown in the accompanying drawings, the combined mud logging sensor of the present invention is equipped with a dynamic adjustment device, and its structure includes a beam 1, a left support standpipe, and a right support standpipe;

[0058] The left section of the beam 1 is provided with a left inner chute channel 2 along the span direction of the beam,

[0059] The left inner chute channel 2 is equipped with a left sliding travel ring 3, and the left sliding travel ring is horizontally slidably connected in the left inner chute channel, and the ring wall of the left sliding travel ring 3 is provided with a left travel ring pin hole 4,

[0060] The left support standpipe 5 vertically penetrates the inner ring hole of the left sliding travel ring, the left slide trave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com