High-efficiency fracturing combined device for multi-stage horizontal well

A combined device and horizontal well technology, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of increasing production and reservoir potential, lack of pertinence and effectiveness of reservoir stimulation, Insufficient seepage area of the contact area and other problems can achieve the effects of economical development of reservoirs, improvement of fracturing efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

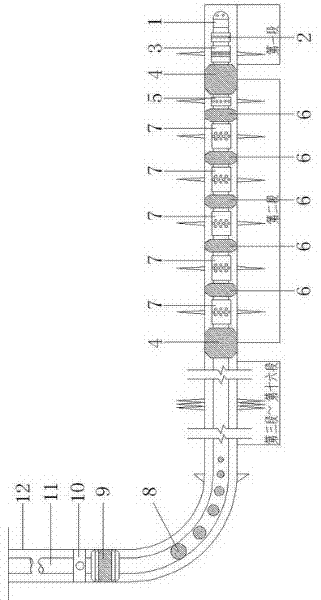

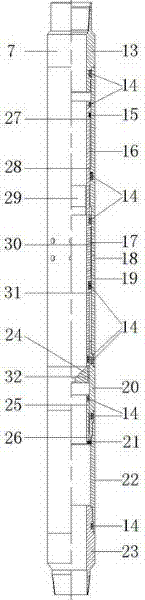

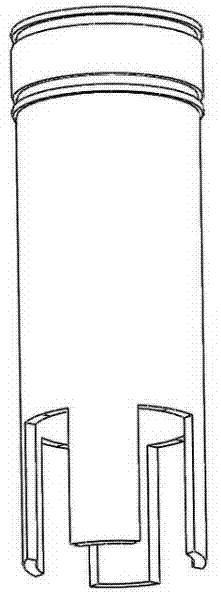

[0015] Depend on figure 1 As shown, a high-efficiency fracturing combination device for multi-stage horizontal wells is composed of an open-hole packer, a high-efficiency fracturing sleeve, a small open-hole packer, and a ball plug fracturing sleeve. Packer, high-efficiency fracturing sleeve, small open hole packer, high-efficiency fracturing sleeve, small open-hole packer, high-efficiency fracturing sleeve, small open-hole packer, high-efficiency fracturing sleeve, small open-hole packer The high-efficiency fracturing sleeve, small open hole packer, ball plug fracturing sleeve, and open hole packer are connected in sequence to form the second high-efficiency fracturing combination device. The upper end of the second high-efficiency fracturing combination device is connected with The third section to the sixteenth section of high-efficiency fracturing combination devices with the same structure are connected with the first section of conventional fracturing devices at the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com