Alignment verification method for exposure machine

A verification method and technology of exposure machines, which are applied in the fields of photomechanical processing of originals, microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problem of unmeasurable, rough, and inability to know alignment accuracy problems, to achieve the effect of being conducive to quality control, quality assurance, and reducing the amount of plate washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

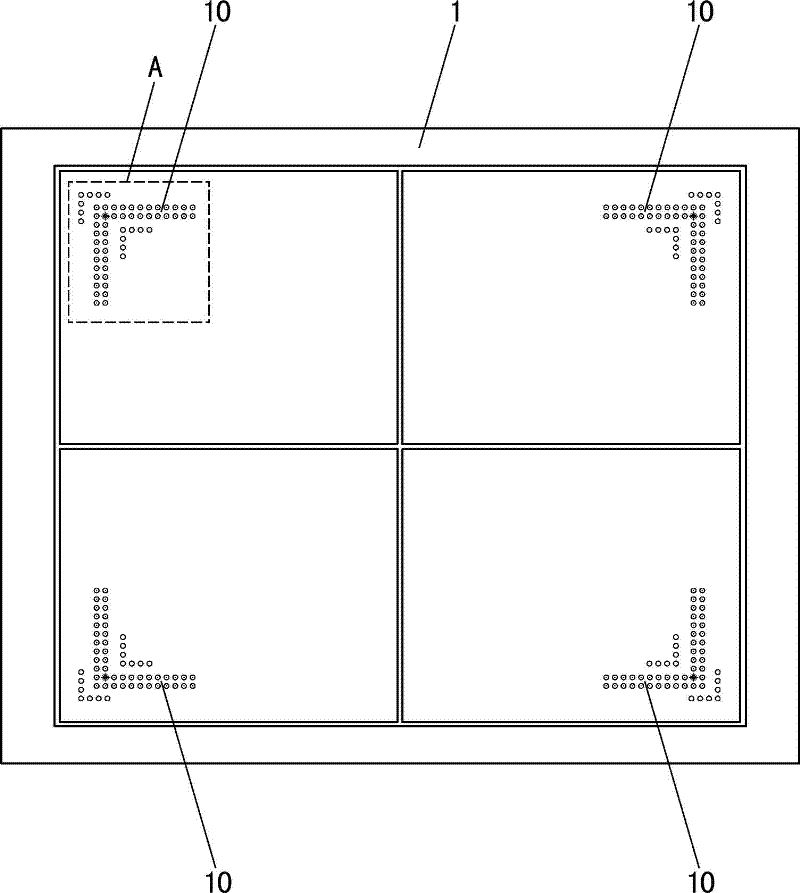

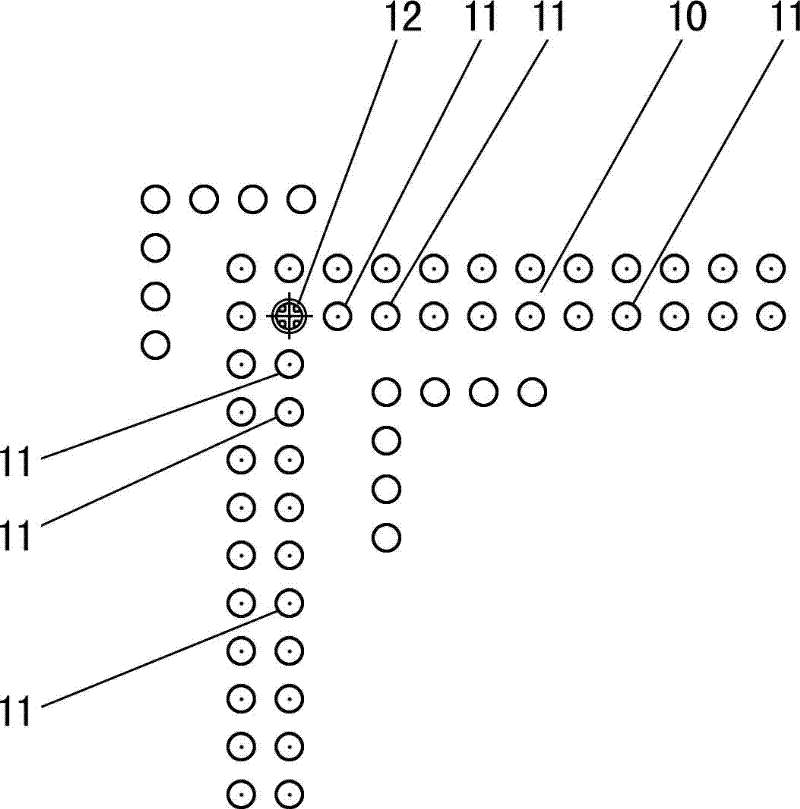

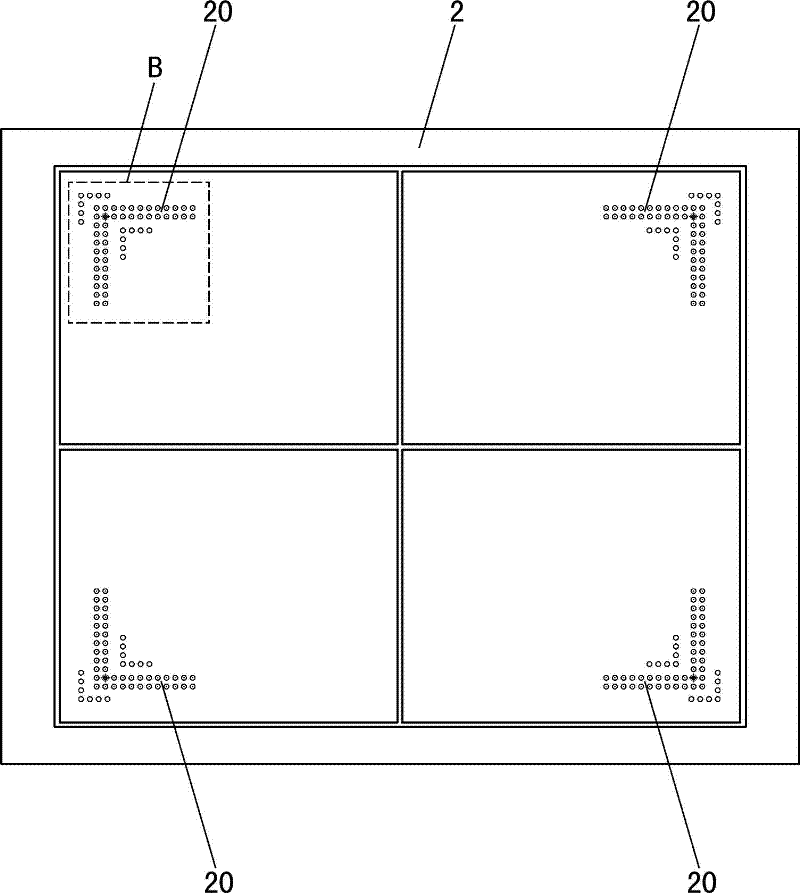

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Such as Figure 1 to Figure 8 As shown, the alignment verification method of the exposure machine in this preferred embodiment includes the following steps:

[0046] (1) Design of lower film 1:

[0047] Such as figure 1 and figure 2 As shown, the four corners of the lower film 1 are respectively provided with an alignment circle arrangement structure 10, the above-mentioned alignment circle arrangement structure 10 includes a plurality of alignment circles 11, and the above-mentioned plurality of alignment circles 11 includes an alignment reference circle 12. The above-mentioned multiple alignment circles 11 are separated from each other, the radius of the above-mentioned multiple alignment circles 11 is the same, the centers of the circles are arranged in a straight line, and the center distances are equal; in order to improve the accuracy o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com