Method for suppressing low-frequency vibration of compressor and system for suppressing low-frequency vibration of compressor

A compressor and dynamic phase technology, applied in the control system, vector control system, control electromechanical brake, etc., can solve the problems of increased power consumption, pipe breakage, phase delay, etc., and achieve the effect of reducing vibration and pipeline stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

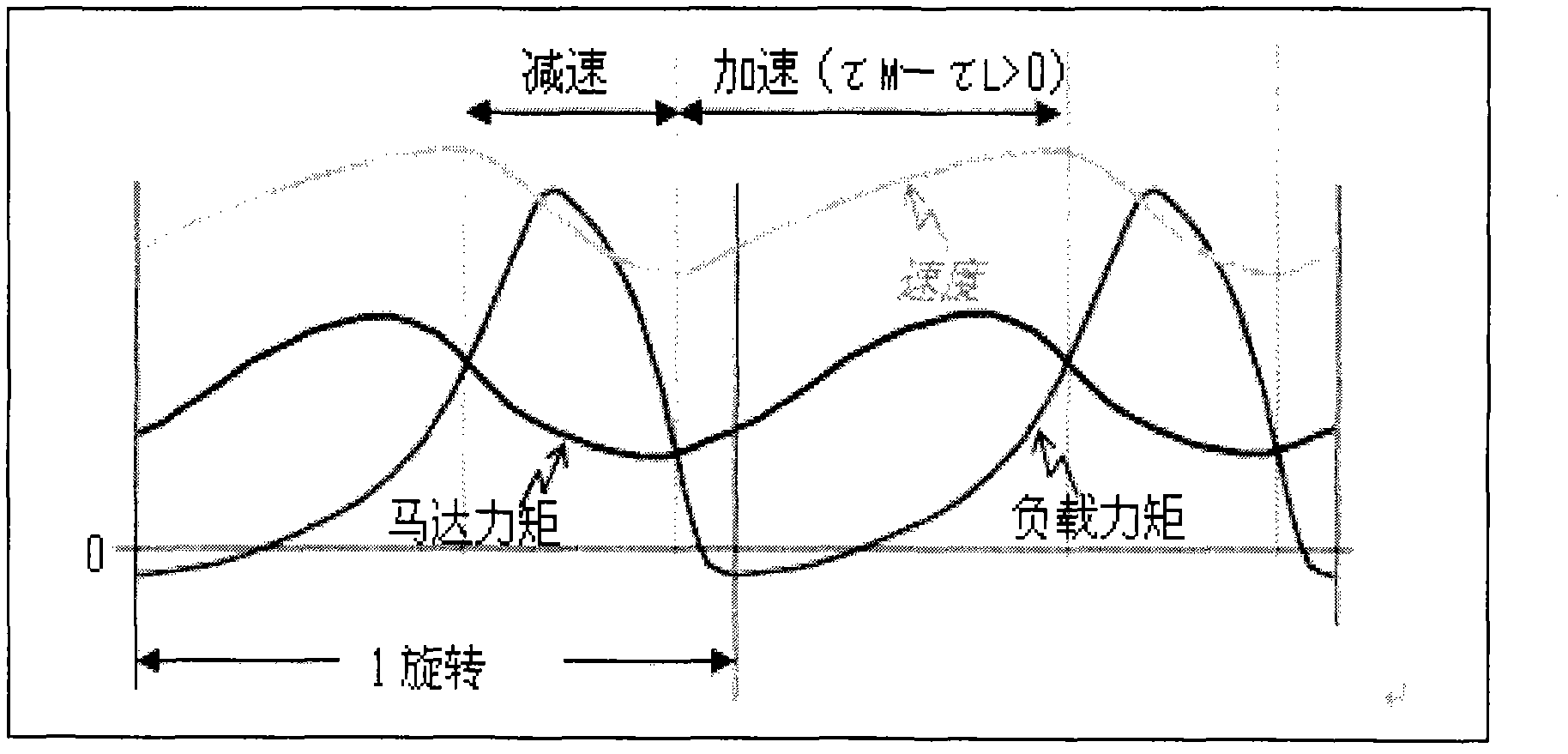

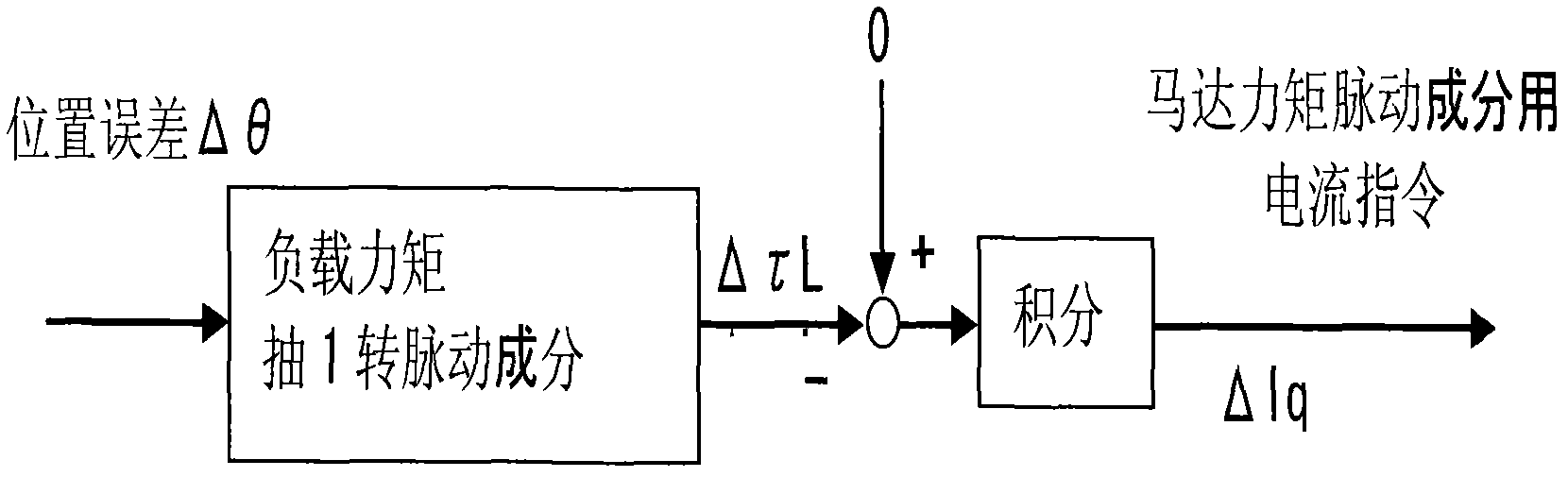

[0068] In the actual control process of compressor operation, because the phase and magnitude of the pulsating load torque cannot be detected, only the phase of the pulsating speed is detected first. According to the phase of the pulsating speed, only the phase portion determined in the pre-experiment is used to determine the phase of the motor torque. on the delayed phase side.

[0069] ■Phase difference α between load torque and motor torque M-L , the phase difference α M-L The value of is neither detectable nor directly controllable

[0070] ■Motor torque / load torque ratio k M , the torque ratio cannot be detected nor directly controlled

[0071] ■Phase difference α between pulsating speed and motor torque M-ω180 or beta ω-M , the phase difference can be controlled first with reference to Figure 11 , to clarify the relationship between the above three variables.

[0072] Figure 11 The condition in is: k M = 0.8, α M-L = 25 degrees, β M-L = 39 degrees, α M-ω180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com