Decoupling control method for bogie suspension system of electromagnetic maglev train

A maglev train and decoupling control technology, applied in electric vehicles, electric traction, vehicle components, etc., can solve the problems of complex bogie structure and function, complex bogie structure, shortened service life, etc., and achieve structural overhaul and maintenance. Difficulty reduction, good track tracking ability, the effect of reducing the amount of elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

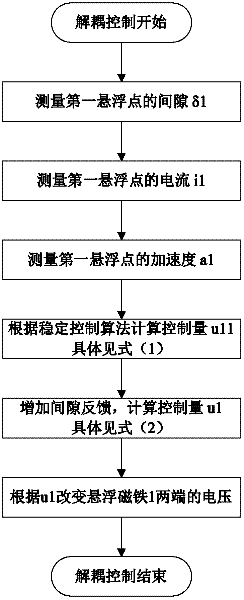

[0042] A kind of decoupling control method of the bogie suspension system of electromagnetic type maglev train of the present invention, its steps are:

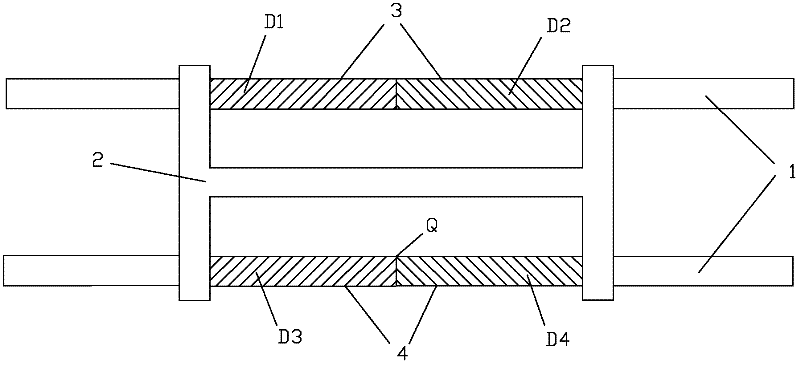

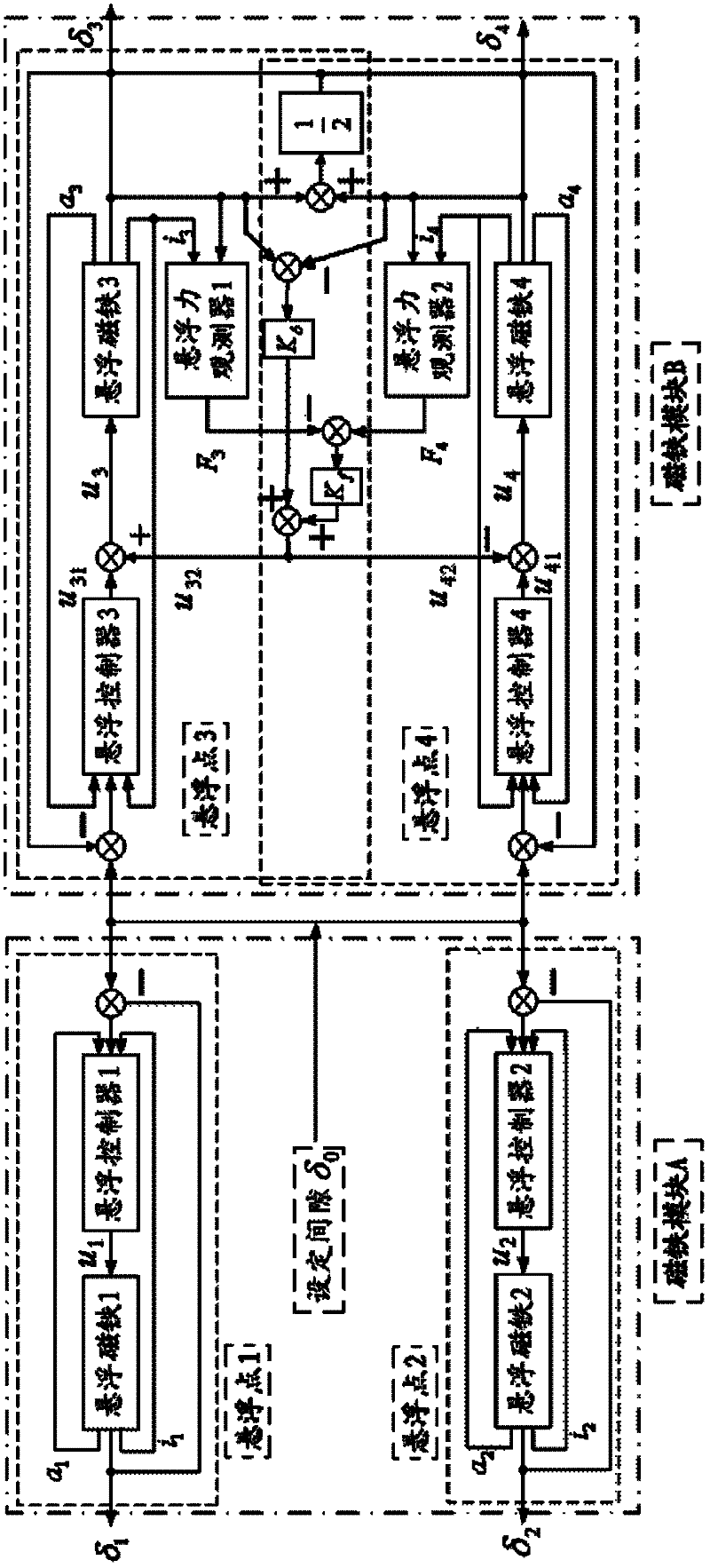

[0043] 1. Set the floating point: such as figure 1 As shown, the bogie 2 is usually placed on the track 1, on which two magnet modules are installed, namely the magnet module A 3 and the magnet module B 4 , which are respectively located on both sides of the bogie 2 . In the present invention, the magnet module A3 is divided into two suspension points for control, i.e. the first suspension point D1 and the second suspension point D2; the magnet module B4 is divided into two suspension points for control, i.e. the third suspension point D3 and the second suspension point D2. Four suspension points D4. By changing the currents of these four suspension points, the suspension control o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com