Holding structure of safety belt

A technology of seat belts and retainers, which is applied in the direction of belt fixing devices, etc., can solve problems such as the deterioration of the cabin environment, the reduction of appearance quality, and the increase of forming costs, and achieve the effects of improving appearance quality, low forming costs, and improving the environment

Inactive Publication Date: 2012-07-04

SUZUKI MOTOR CORP

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] With the above-mentioned conventional structure, in order to integrally form the seat belt holder and the retaining face for clamping and holding the middle part of the seat belt in the longitudinal direction on the upper end of the lower interior part, complex tools such as slide molds must be used. Die structure for forming, resulting in higher forming costs

In addition, in the case of molding with a knockout hole in the retaining surface without using a slide mold, depending on the viewing angle, the body panel or the like located inside the interior part may be seen, resulting in a decrease in appearance quality, or Causes driving noise and dust to enter the cabin and deteriorates the environment in the cabin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

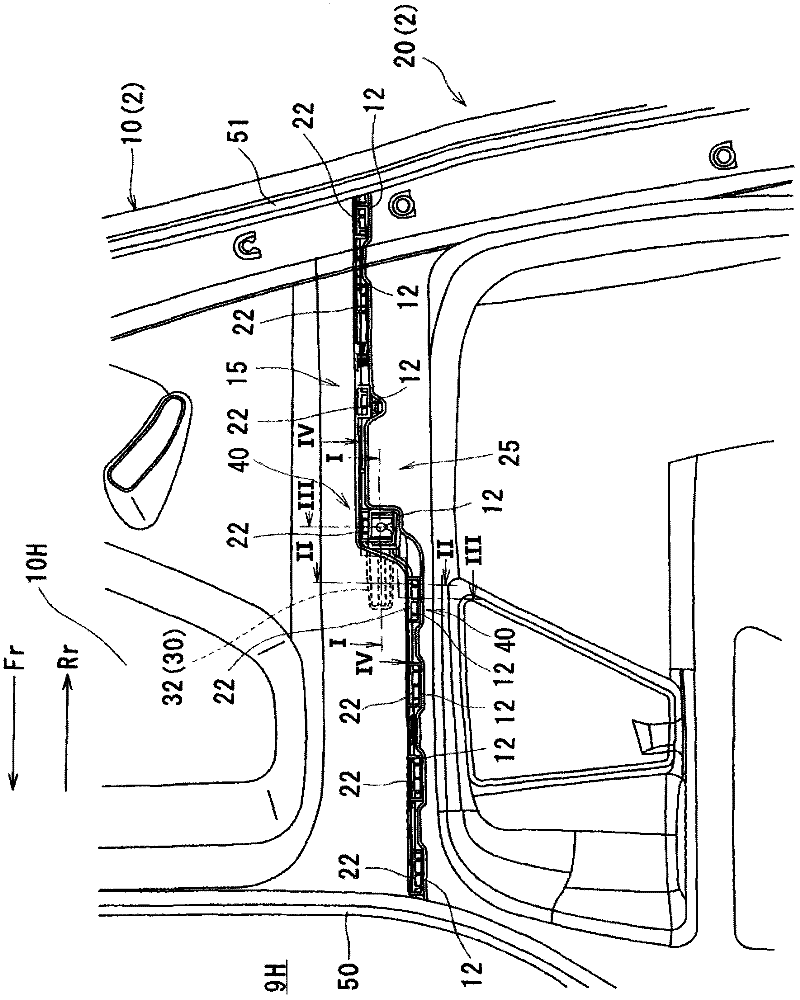

[0063] The seatbelt holder 30 may be integrally formed on the appearance surface side of the lower end portion of the upper garnish 10 to face the retaining surface on the appearance surface side of the lower garnish 20 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

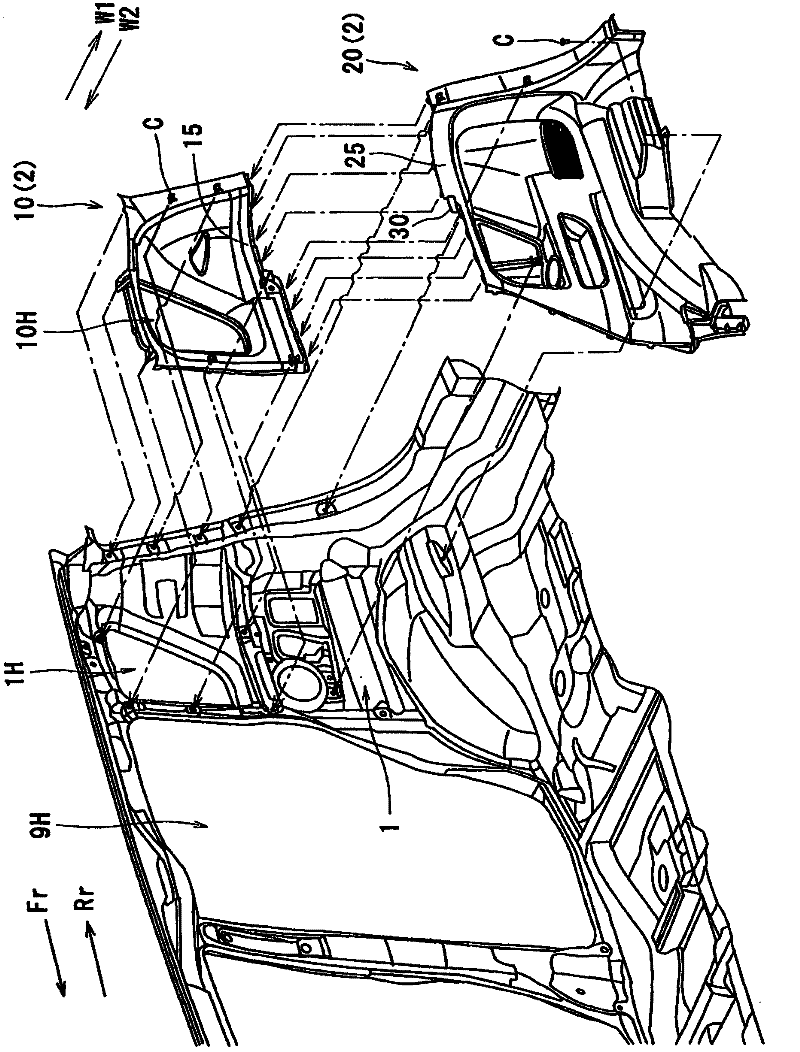

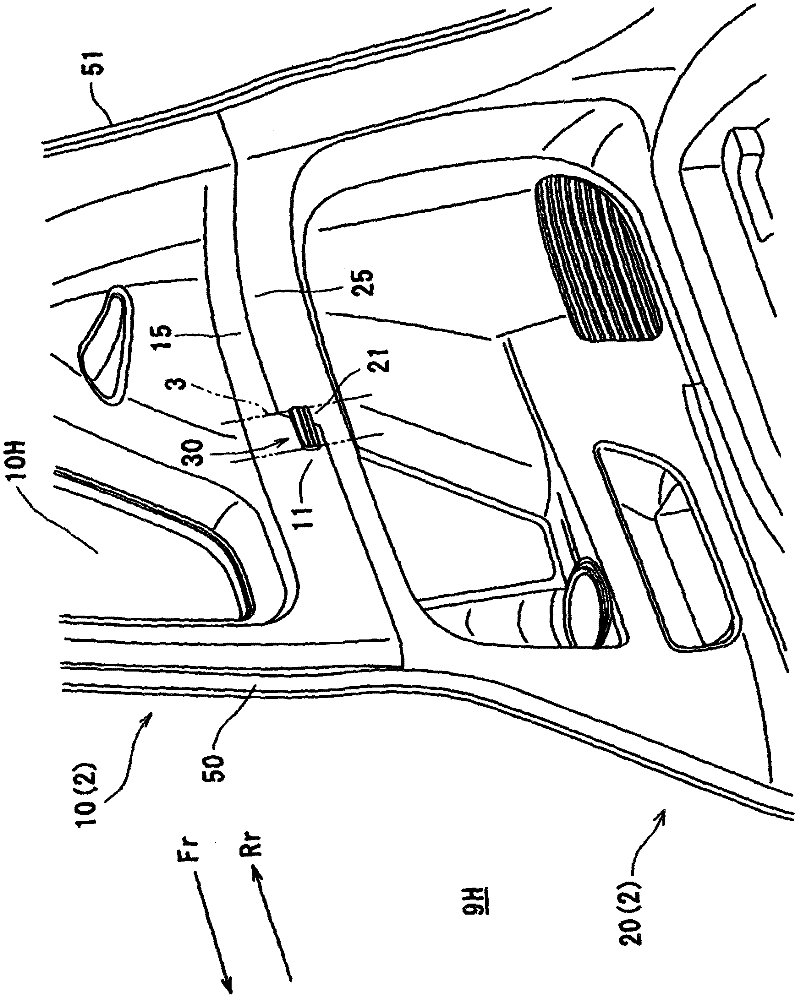

The present invention provides a holding structure of a safety belt, which has the following functions: reducing forming cost, improving appearance quality and improving environment in the carriage. An inner decoration component (2) has a vertical two-part structure which is composed of an upper inner decoration component (10) and a lower inner decoration component (20). An appearance surface (20M) side of the inner decoration component is provided with a safety belt holding member (30) which is used for snapping and holding the safety belt (3). The safety belt holding member is integrally formed at a random one selected from a lower end of the upper inner decoration component in mutual connection, and furthermore projects from a sub-molding-surface of the random one. The safety belt holding member furthermore opposes a holding surface (17) of the appearance surface side of the other member in the lower end of the upper inner decoration component and the upper end of the lower inner decoration component. The safety belt is inserted between the safety belt holding member and the holding surface and is jointed with the safety belt holding component.

Description

technical field [0001] The present invention relates to a retaining structure for a seat belt, which is provided with a seat belt retainer for engaging and holding a seat belt on the exterior surface side of an interior trim part, the interior trim part is mounted on a body panel (Japanese: car body panel) and The upper and lower interior parts constitute a two-divided structure. Background technique [0002] The rear seat of the automobile is provided with a three-point seat belt device in which the middle portion of the seat belt in the longitudinal direction passes through a shoulder ring provided on a body panel on the side of the rear seat. [0003] On the other hand, as for the rear seats, there is a reclining type rear seat in which the seat back can be folded onto the seat cushion so that the trunk in the rear of the compartment can be expanded toward the front side of the vehicle. [0004] In a car having the above-mentioned three-point seat belt device and a recli...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60R22/24

Inventor 大中阳介

Owner SUZUKI MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com