Orbit shuttling load transferring trolley used for stereoscopic warehouse

A technology of three-dimensional warehouses and trolleys, which is applied in the direction of transportation, packaging, and conveyors. It can solve problems such as collision with shelves and occupation of warehouse use volume, and achieve the effects of increasing use volume, light structure, and improving safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

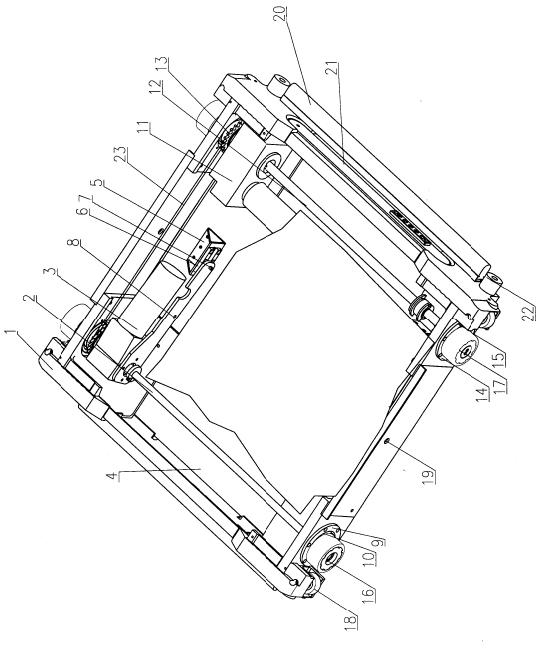

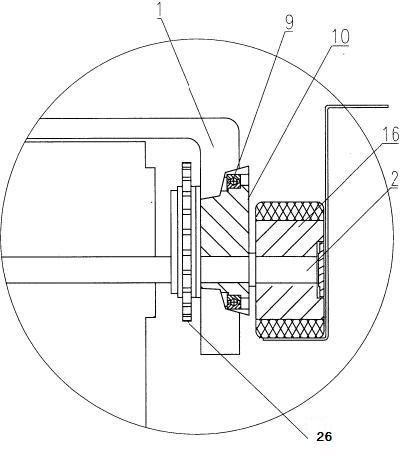

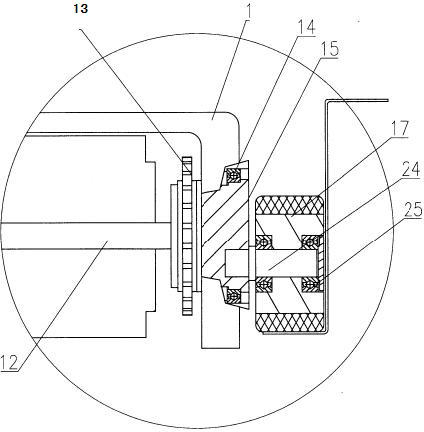

[0011] A rail shuttle transfer trolley for a three-dimensional warehouse, comprising a rectangular trolley frame 1, a pair of active eccentric bearing seats 9 are respectively fixedly fixed on the two sides of the front end of the trolley frame 1, in the pair of active eccentric bearing seats 9 respectively Corresponding activities are provided with a pair of active eccentric bushings 10, an eccentric hole is arranged at the eccentric position of the active eccentric bushing 10, and an eccentric driven lifting sprocket 26 is fixedly connected to the inner side of the active eccentric bushing 10 on the right side. The center line of the eccentric hole of the moving lifting sprocket 26 and the center line of the eccentric hole on the active eccentric bushing 10 are on a straight line, and one end of the trolley walking driving shaft 2 passes through the eccentric hole on an active eccentric bushing 10, and the trolley The other end of the walking driving shaft 2 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com