High-efficiency hand-operated type dewaterer with braking device

A braking device and a hand-cranked technology, applied in the field of dehydrators, can solve the problems of inconvenient use, waste of electric energy by dehydrators, etc., and achieve the effects of cost reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

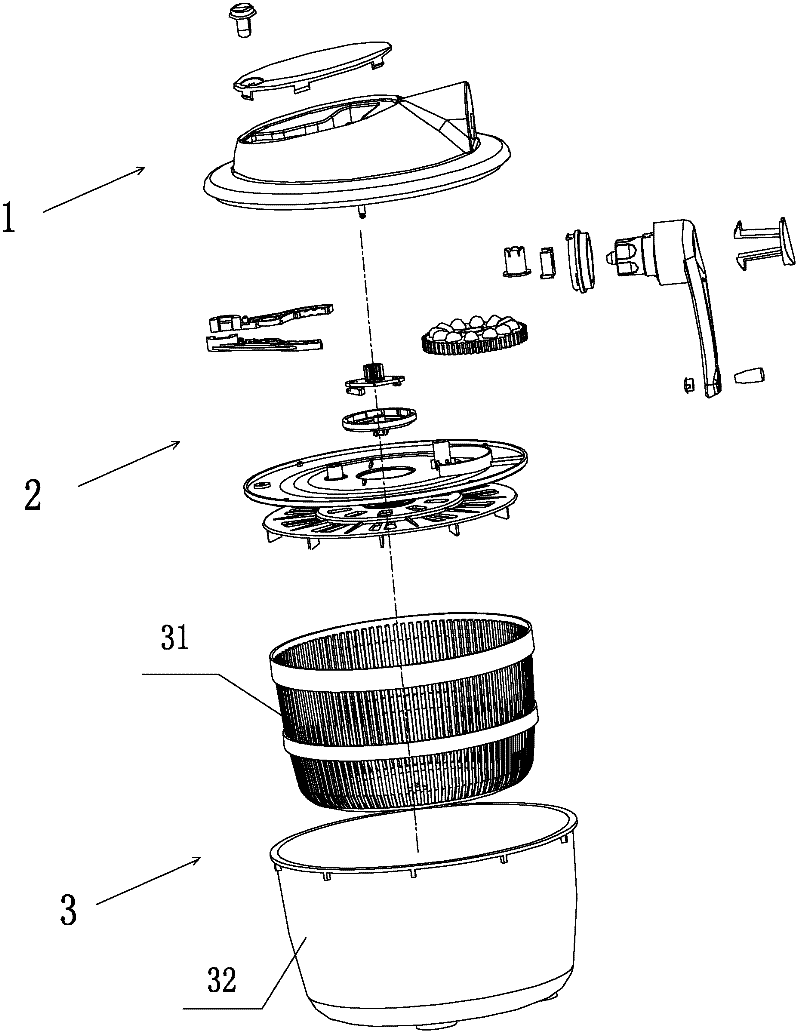

[0017] refer to figure 1 , The dehydrator of the present invention is composed of top protection device 1, hand-operated driving device 2 and dehydration device 3 from top to bottom.

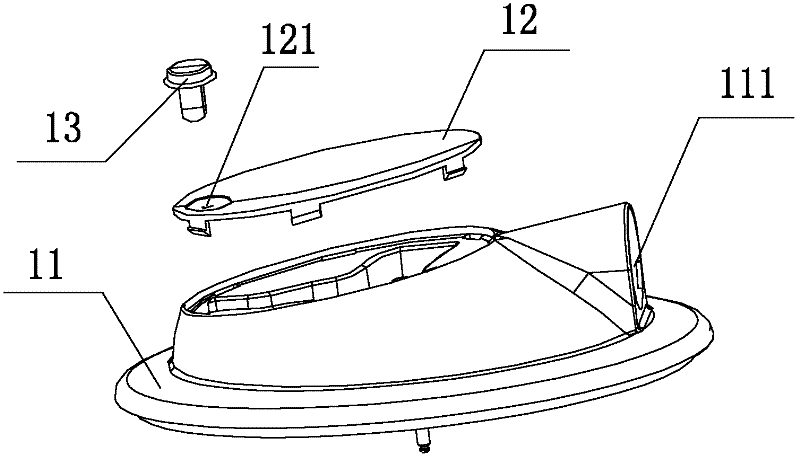

[0018] refer to figure 2 , the support of the top protection device 1 is a top cap 11, and a rocker installation hole 111 fixed by a rocker installation ring 253 is formed on the edge of the top cap, a top cover 12 is installed on the top of the top cap 11, and a A button mounting hole 121 for the brake button 13 to be installed.

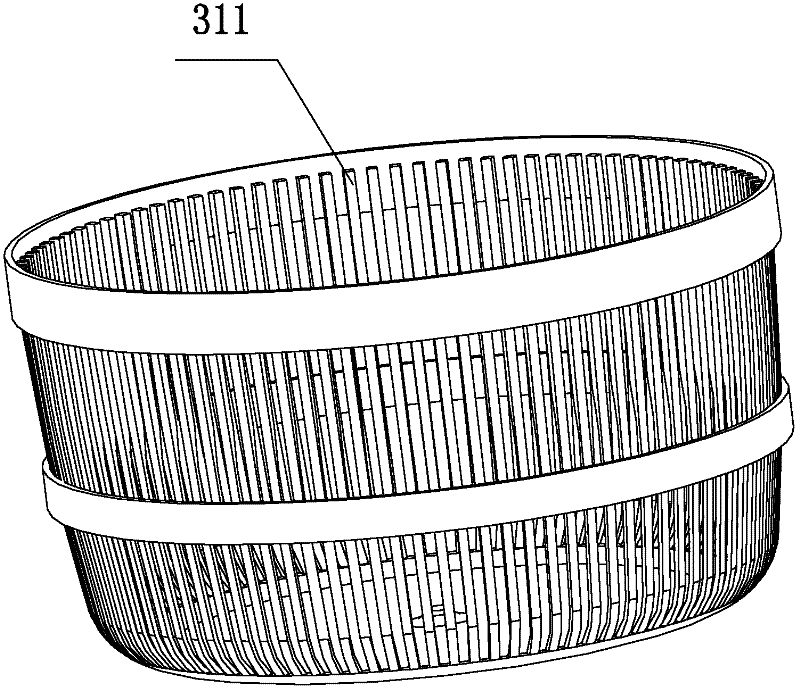

[0019] refer to figure 1 with image 3 , dehydration device 3 comprises dehydration basket 31 and dehydration bucket 32, and dehydration basket 31 is positioned at dehydration bucket 32 and is fixed with it, and the basket wall of dehydration basket 31 is made grid-like, and its grid bar 311 protrudes inwardly, and dehydration bucket 32 There is a through hole at the bottom for drainage.

[0020] refer to Figure 4 , The hand-operated driving device 2 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com