Sintering machine tail red cross section effective image automatic capture method

An effective image, automatic capture technology, applied in the direction of computer parts, instruments, character and pattern recognition, etc., to achieve the effect of easy implementation, low equipment cost, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0018] The equipment of the method is constituted by installing an image acquisition device at the tail of the sintering machine, and the image acquisition device may be a video camera, a camera with a camera function and other imaging equipment. The image acquisition device is connected with the computing device, and the computing device is responsible for checking the validity of the collected images, and the computing device may be a computing device such as a computer or a single-chip microcomputer. After the validity of the image is determined, the effective image of the red section of the sintering machine tail can be stored or further analyzed.

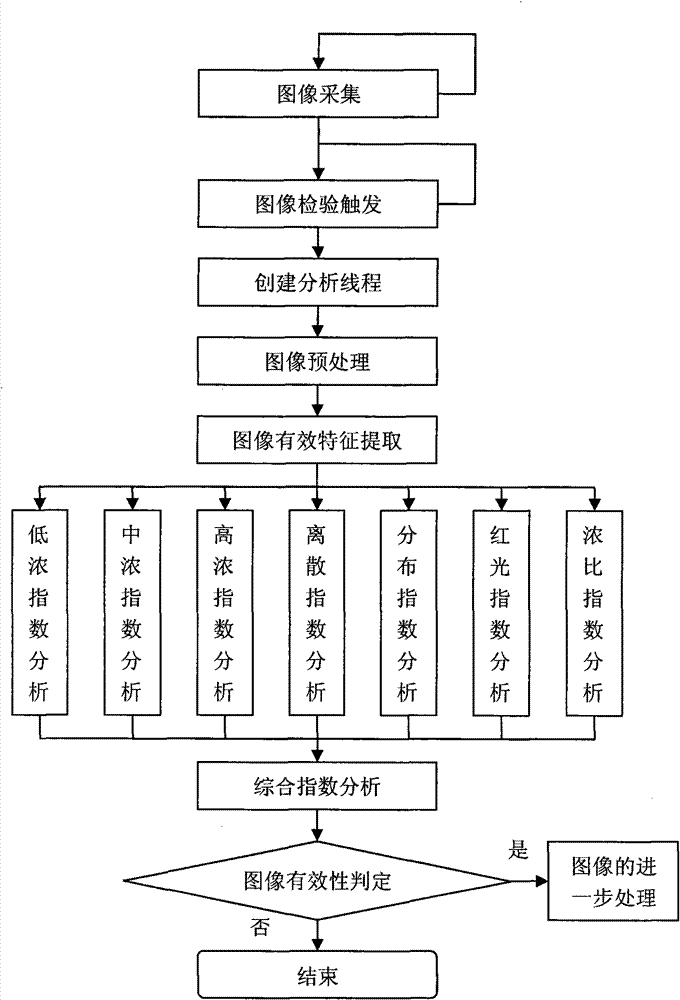

[0019] like figure 1 As shown, the process flow of the method for detecting the validity of the sintering machine tail red section image of the present invention is as follows:

[0020] Step 1: I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com