Electroplating structure for golden fingers of flexible circuit board

A flexible circuit board and flexible circuit technology, applied in the electronic field, can solve the problems affecting the appearance quality of the circuit board, uneven surface brightness, uneven thickness of the coating, etc., and achieve the effect of good appearance, uniform brightness, and uniform thickness of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

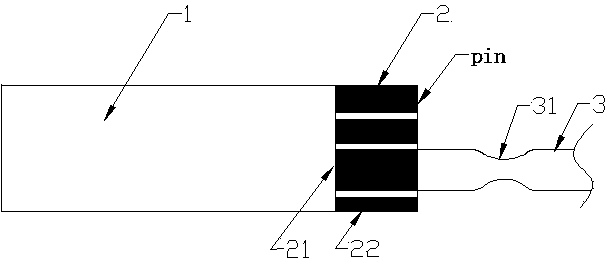

[0014] Such as figure 1 As shown, in the present invention, when the film is designed and manufactured by CAM software, the flexible circuit board 1 gold finger 2 is improved and designed, and the size of each pin pin in the terminal area of the flexible circuit board 1 gold finger 2 is adjusted according to the size of the plated surface. The thickness of the external electroplating wire 3 connected to the gold finger 2, the size of the plated surface of each pin in the gold finger 2 is different, that is, the thickness and width of the pins are different, and there are at least two thick pins 21 and thin pins 22 with different thicknesses. . In this embodiment, a bottleneck 31 is set on the electroplating line 3 outside the molding connected to the thick pin 21, that is, an area of reduced area, so that an area of reduced area is formed on the electroplating line 3 (other electroplating lines do not change, as shown in the figure not shown), so as to reduce the curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com