Apparatus and method for inserting bags

A technology of equipment and valve pockets, which is applied in the field of equipment for inserting and placing bags, can solve the problems of difficulty in straightening independent valve pockets and difficulty in inserting and placing valve pockets, and achieves high insertion and placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

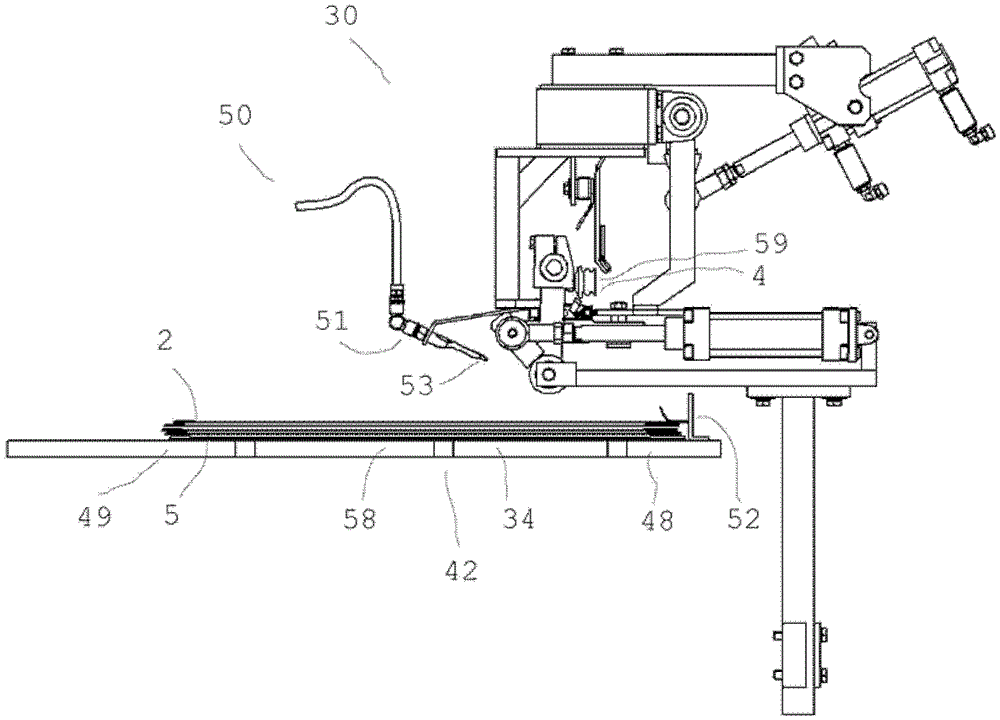

[0062] Some exemplary embodiments of the device according to the invention will be described below with reference to the accompanying drawings.

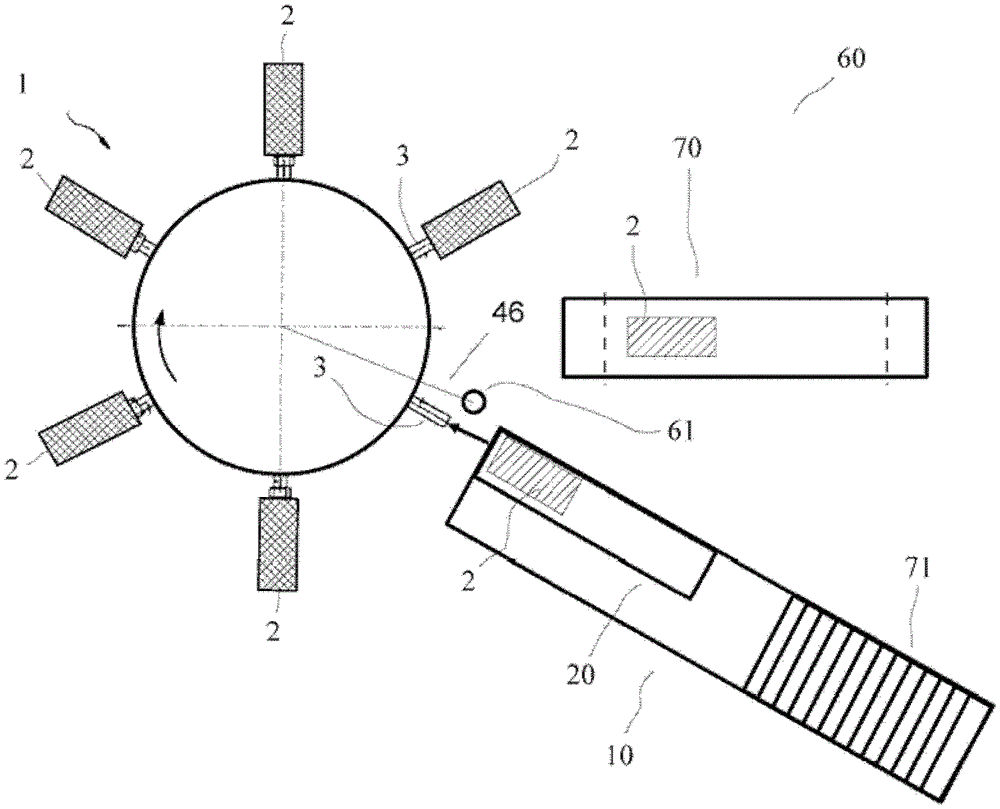

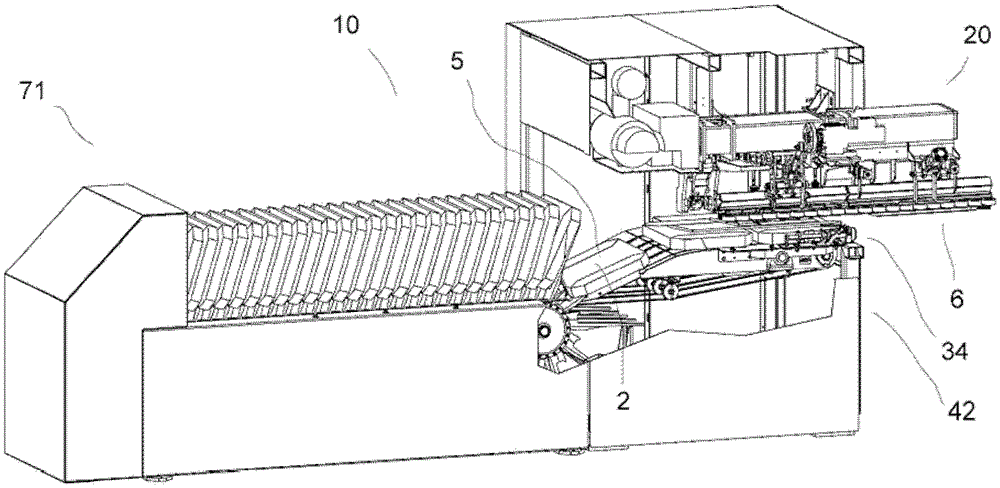

[0063] figure 1 A simplified top view of a packaging system 60 comprising a rotary packaging machine 1 and a placement device 10 as well as an unloading conveyor 70 is shown.

[0064] The packaging machine 1 is used for filling valve pockets 2 and, in the presently shown embodiment, comprises six circumferentially distributed filling openings 3 , of which five filling openings 3 are arranged with valve pockets 2 .

[0065] The packaging machine 1 is shown in the insertion position. The angle sensor 61 has previously sensed the next filling opening 3 rotating past the predetermined angular position 46 , thus triggering the next insertion operation. Instead of using sensors for the insertion device 10 , it is also conceivable to use sensors on the packaging machine for detecting the predetermined angular position 46 .

[0066] The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com