Mechanical and electronic composite lock

A mechatronic and compound lock technology, which is applied to locks controlled by non-mechanical transmission, building locks, buildings, etc., can solve the problems of solenoid valve locks that are difficult to open, have no emergency opening function, and get out of the working position, etc., so as to achieve a reasonable and practical overall structure , Protect the electromagnet core, enhance the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

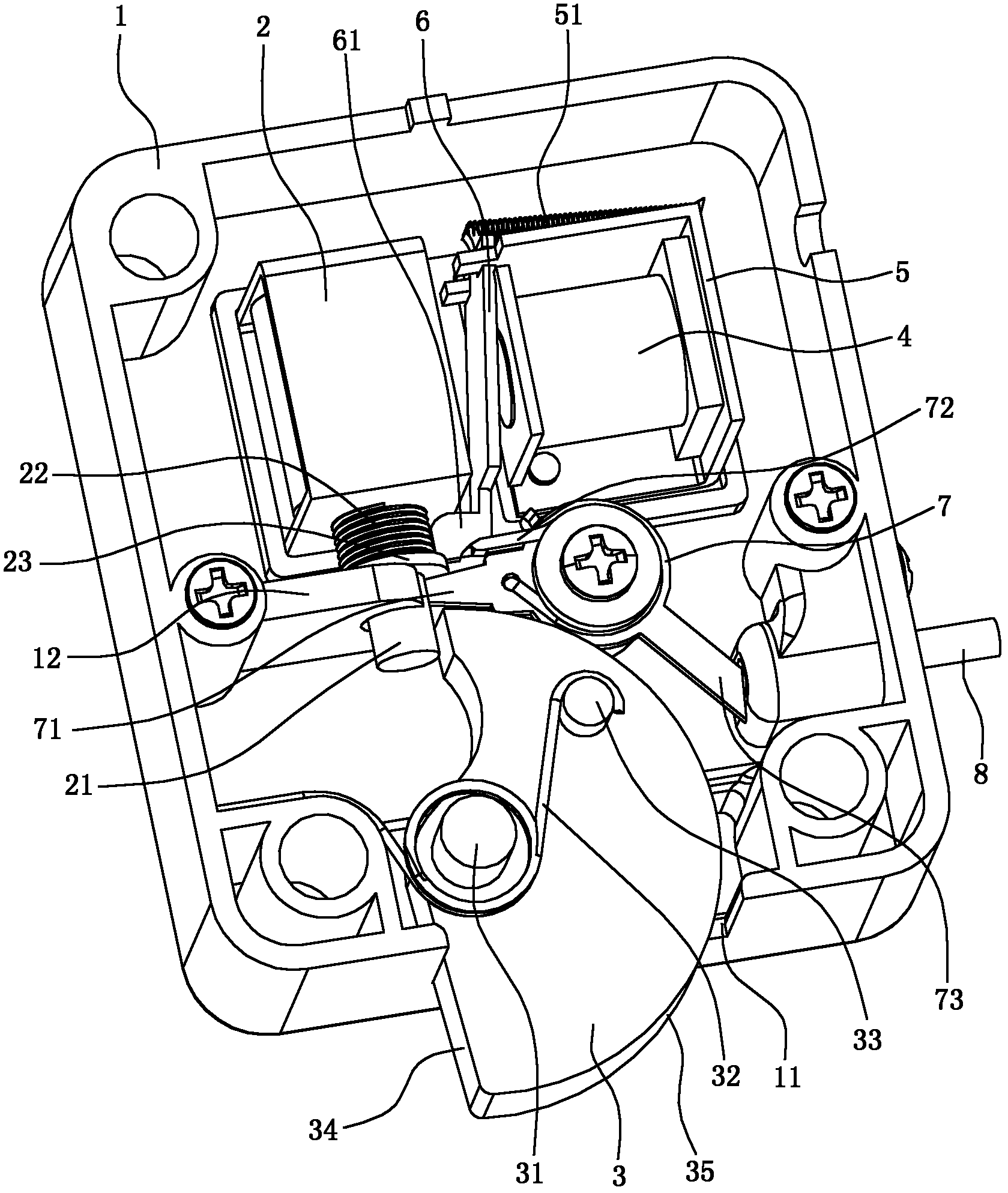

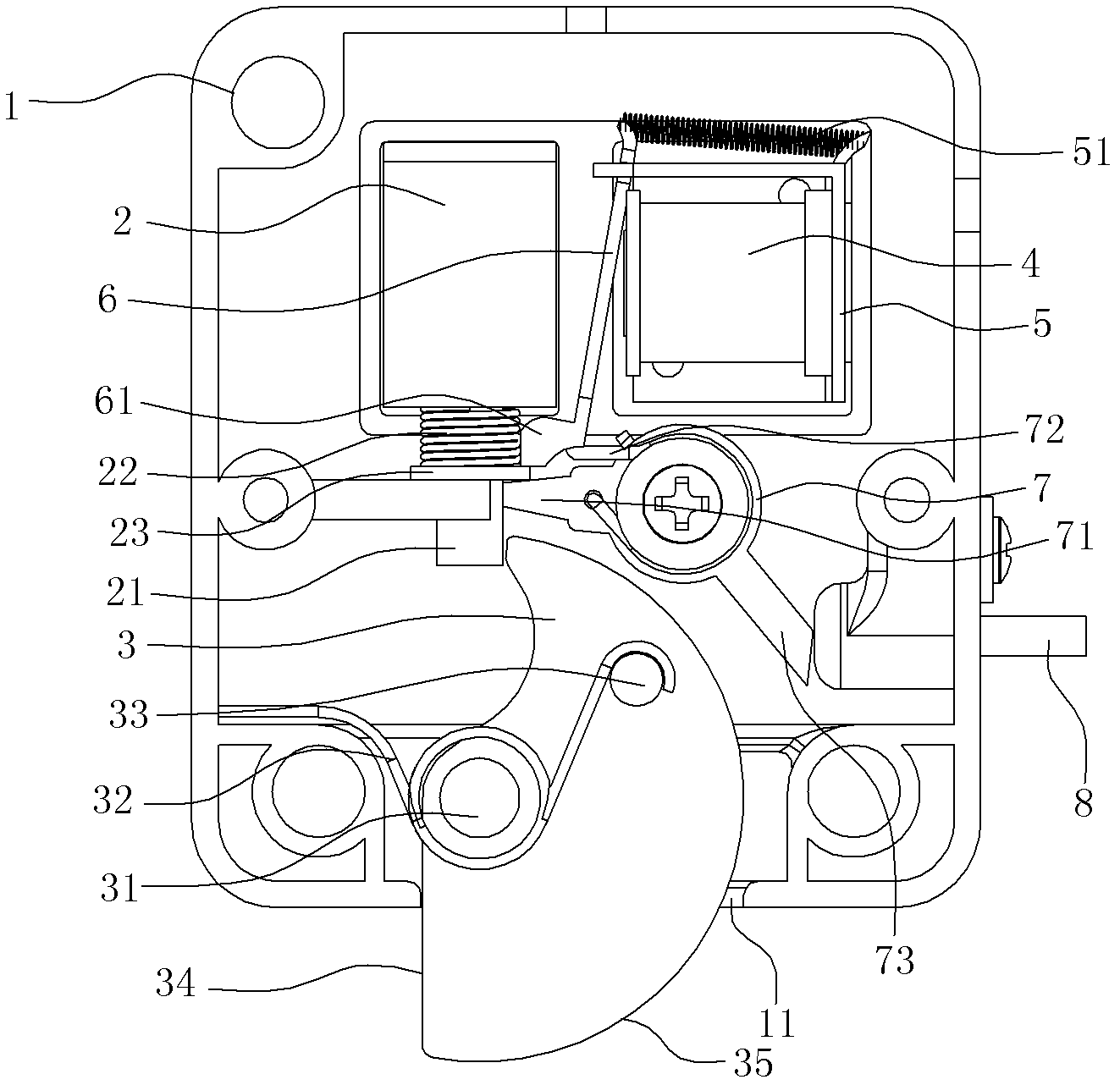

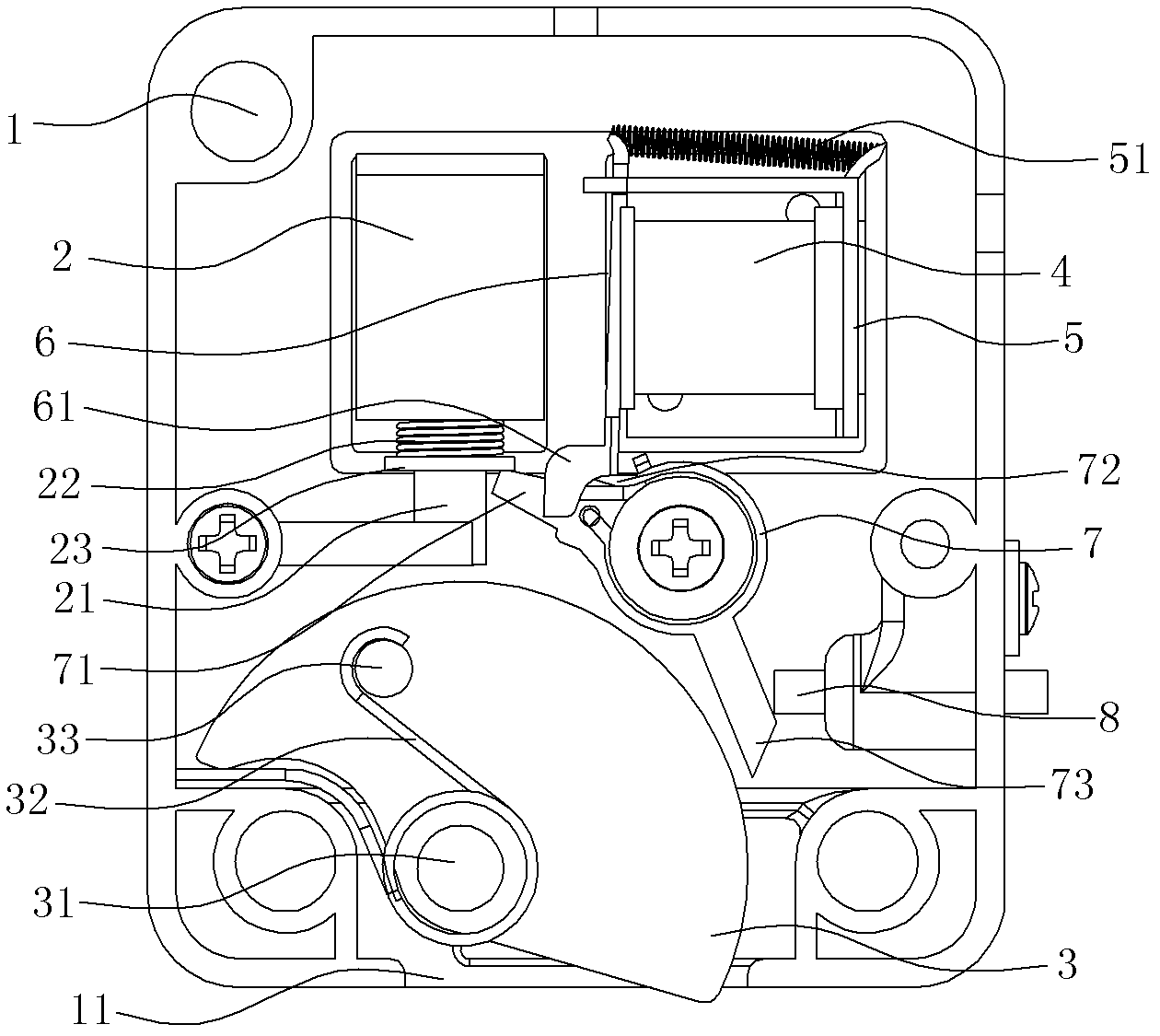

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] Such as Figure 1~5 Shown is a preferred embodiment of the present invention.

[0025] A mechanical and electronic composite lock, comprising a lock case 1, the lock case 1 has an upper case and a lower case connected together by screws, and the lock case 1 is provided with a solenoid valve lock 2 with a retractable electromagnet core 21, and the electromagnet The core 21 is covered with a spring 22 and is fixed with a retaining ring 23. The spring 22 acts on the retaining ring 23 and keeps the electromagnet core 21 moving downward; The notch 121 through which the magnet core 21 passes, the retaining ring 23 is in contact with the upper end surface of the baffle plate 12 when the electromagnet core 21 is kept stretched out.

[0026] The lock housing 1 is connected with a deadbolt plate 3 through a rotating shaft 31 in rotation. The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com