Pipe connection arrangement

A technology for connecting structures and pipes, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, packing and sealing connection with fluid pressure, etc. Achieve the effect of suppressing oscillation or vibration and avoiding material fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

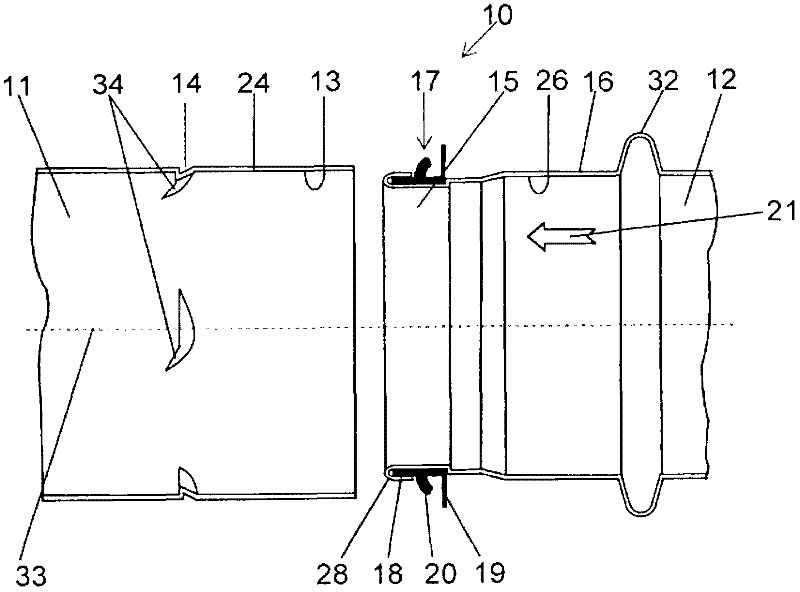

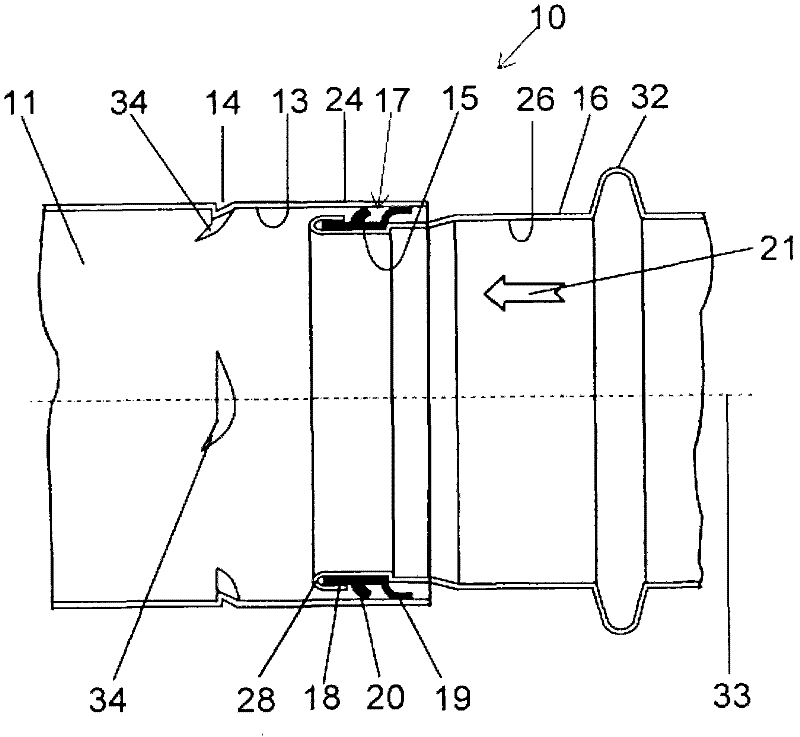

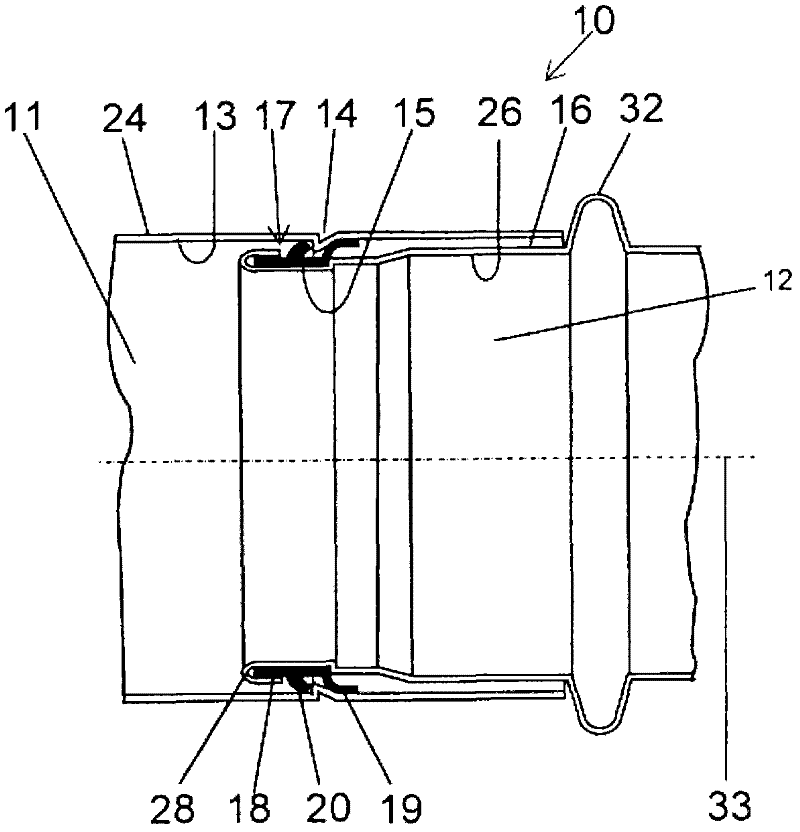

[0034] Figure 1 to Figure 5 A longitudinal sectional view of the pipe connection structure 10 in the first embodiment of the present invention is shown. The pipe connection structure 10 includes a first pipe piece 11 and a second pipe piece 12 , wherein a locking mechanism 14 is provided on the pipe inner wall 13 of the first pipe piece 11 . Therefore, a plurality of locking mechanisms 14 can likewise be provided on the inner tube wall 13 . The number of locking mechanisms 14 is mainly determined by the diameters of the first and second pipes 11 , 12 . Preferably, said locking mechanism 14 is arranged axisymmetrically with respect to the longitudinal axis 33 of the first or second tubular member 11 , 12 . The end 15 of the second pipe 12 is inserted into the first pipe 11 . Thus, the outer diameter of the second pipe 12 at the end 15 is smaller than the inner diameter of the first pipe. Of course, it is also an option that the outer diameter of the second pipe member 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com