Housing of vehicle electronic control unit

A technology for electronic control units and casings, which is applied in the field of casings of electronic control units for vehicles, and can solve the problems of time-consuming and labor-intensive thin plates, reduced manufacturing efficiency, and high cost of waterproof thin plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

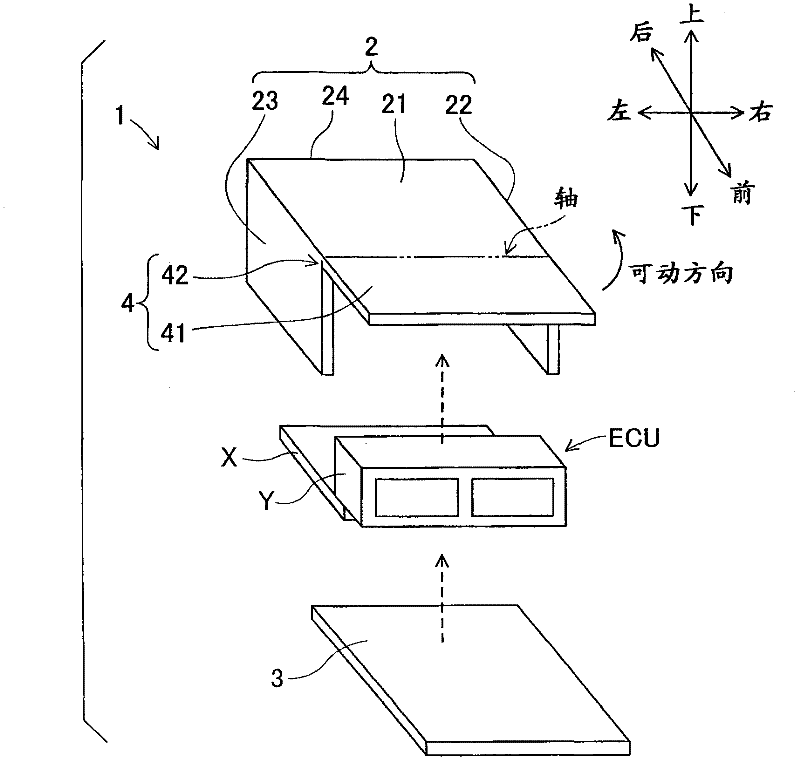

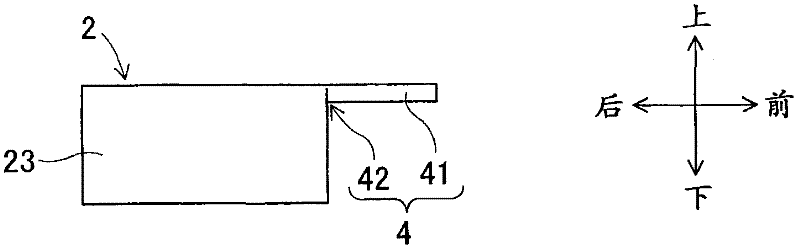

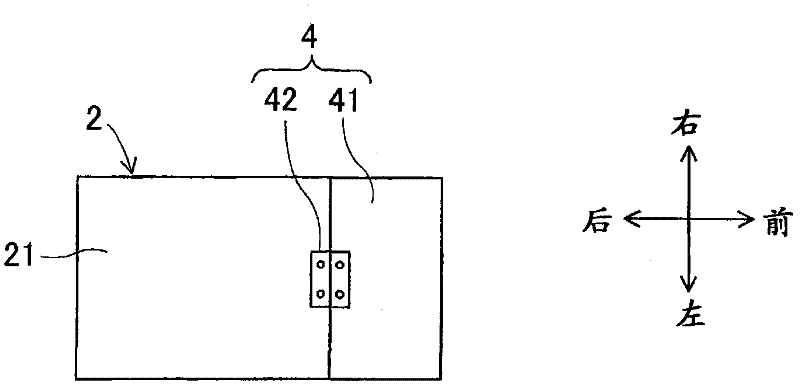

[0023] like figure 1 As shown in , an enclosure 1 of an ECU for a vehicle includes a housing 2 , a cover 3 and a waterproof cover 4 .

[0024] The casing 2 is made of resin, and has an approximately rectangular parallelepiped shape. A lower portion and a side portion (for example, a front portion) of the housing 2 housing the ECU inside are open. Specifically, the housing 2 has an upper wall 21 , a right wall 22 , a left wall 23 and a rear wall 24 .

[0025] The cover 3 is a plate member made of metal or resin, and closes the opening in the lower portion of the housing 2 . The cover 3 is fixed to the lower part of the housing 2, for example, by screws (not shown). The ECU is fixed to the cover 3 and housed in the housing 2 .

[0026] The waterproof canopy 4 is a plate member made of resin, and is integrally formed with the casing 2 . The waterproof canopy 4 has a canopy member 41 and a movable holding portion 42 . The canopy member 41 protrudes forward from the front end...

no. 2 approach

[0037] like Figure 5 As shown in , in the second embodiment, the housing 10 of the ECU for a vehicle has a case 20 , a cover 3 and a waterproof cover 40 . In the state where the waterproof cover 40 is bent upwards is illustrated Figure 5 The ECU is omitted in .

[0038] The housing 20 has almost the same configuration as the first embodiment, and has an upper wall 21 , a right wall 22 , a left wall 23 , a rear wall 24 and a front edge portion 25 . After defining the opening in the front wall of the housing 2, the front edge portion 25 is defined by the remainder of the front wall. Specifically, the front edge portion 25 has a right portion 251 protruding leftward from the front end of the right wall 22 , and a left portion 252 protruding rightward from the front end of the left wall 23 . A hook hole 25a is defined in each of the right portion 251 and the left portion 252, and corresponds to a hook 412a which will be mentioned later.

[0039]The waterproof canopy 40 is ma...

no. 3 approach

[0050] like Figure 7 As shown in , compared with the first embodiment, in the third embodiment, the housing 1A of the ECU for a vehicle has a detection portion 44 provided on a cover member 41 . The detection portion 44 protrudes downward from the lower surface of the canopy member 41 on the front side.

[0051] like Figure 8B As shown in , for example, when the connectors Y, Z have a half-assembled state, the detecting portion 44 contacts the protruding portion of the vehicle-side connector Z. At this moment, the waterproof canopy 4 cannot have Figure 8A normal state shown in . Specifically, such as Figure 8B As shown in , the canopy 4 cannot become parallel to the upper wall 21 . That is, when the connectors Y, Z are in a semi-assembled state, the waterproof cover 4 is inclined upward relative to the upper wall 21 .

[0052] Instead, as in Figure 8A As shown in , when the connectors Y, Z are completely fitted to each other, the detection portion 44 does not conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com