Method for manufacturing a medical device

A technology of medical containers and syringes, applied in the field of manufacturing medical instruments, can solve troublesome, not optimal, imprecise and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

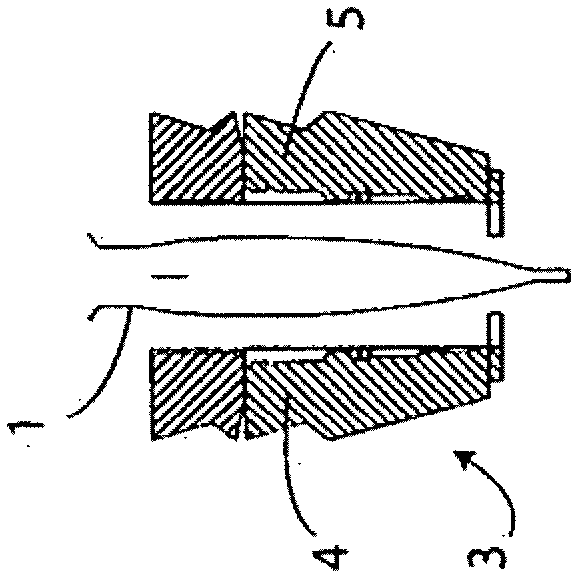

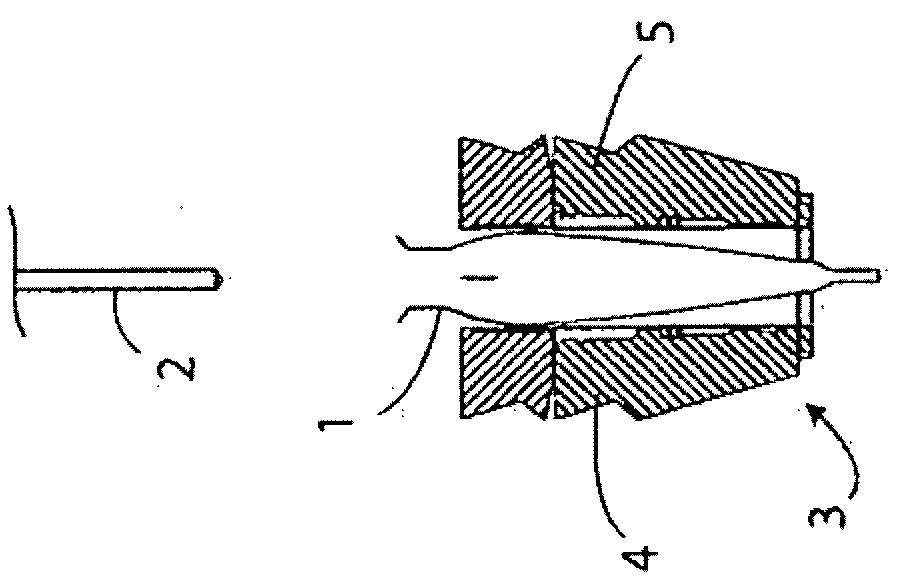

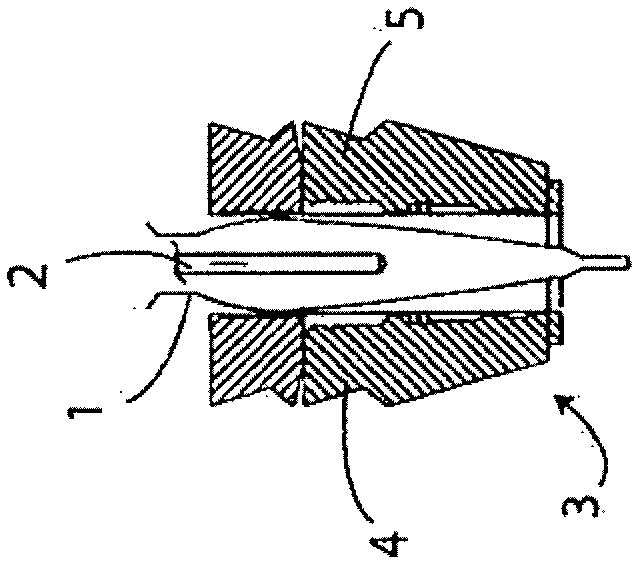

[0038] Methods of extrusion and blow molding of plastic materials for the manufacture of the medical device of the invention are in Figures 1 to 6 Indicated.

[0039] This method includes the following actions:

[0040] - extruding the plastic material in order to obtain a heated tubular element 1 (also called "parison") manufactured from the plastic material in an at least partially molten state, this operation being performed in figure 1 in said;

[0041] - Blow molding on such a tubular element in order to obtain a plurality of medical containers 6 each substantially provided with a neck or local constriction through which liquid or organic substances pass; the operating in Figure 4 summarized in.

[0042] According to the invention, the method comprises the operation of calibrating the entire inner surface 6a of the medical container 6 (see image 3 with 4 ), this operation is carried out after the operation of extruding the plastic material, suitable for making t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com