Sterile double-pipe plate heat exchanger

A technology of double tube sheet heat exchanger and heat exchanger, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of unable to meet process requirements, lowering product grade, inconvenient production, etc. Achieve the effect of strong sterility, good sealing and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] As a preferred embodiment of the present invention:

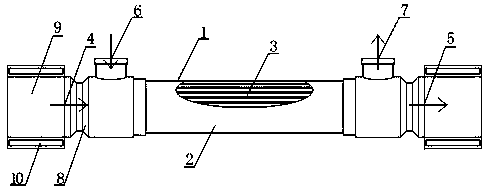

[0017] Such as figure 1 A sterile double-tubesheet heat exchanger is shown, which includes: a heat exchanger body 1; a tube body 2 is provided at the outer end of the heat exchanger body 1, and a heat exchanger is provided at the inner end of the tube body 2. Heat pipe 3, the two ends of the heat exchange tube 3 are respectively connected with a heat medium inlet 4 and a heat medium outlet 5, and the pipe body 2 is respectively connected with a refrigerant inlet 6 and a refrigerant outlet 7. A tube plate 8 is installed on the media inlet 4 and the heat medium outlet 5, and a tube box 9 is installed on the tube plate 8, and a germicidal lamp 10 is arranged in the tube box 9;

[0018] Wherein, the heat exchange tube 3 is provided with a support plate in the tube body 2, and the sealing connection between the heat exchange tube 3 and the tube body 2 is a plane and a circumferential seal, and its plane And the circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com