Preparation device of coating for organic photo conductor drum coating

A photosensitive drum and coating technology, which is applied in the field of preparation equipment for organic photosensitive drum coating coatings, can solve the problems of low dispersion strength and achieve a stable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

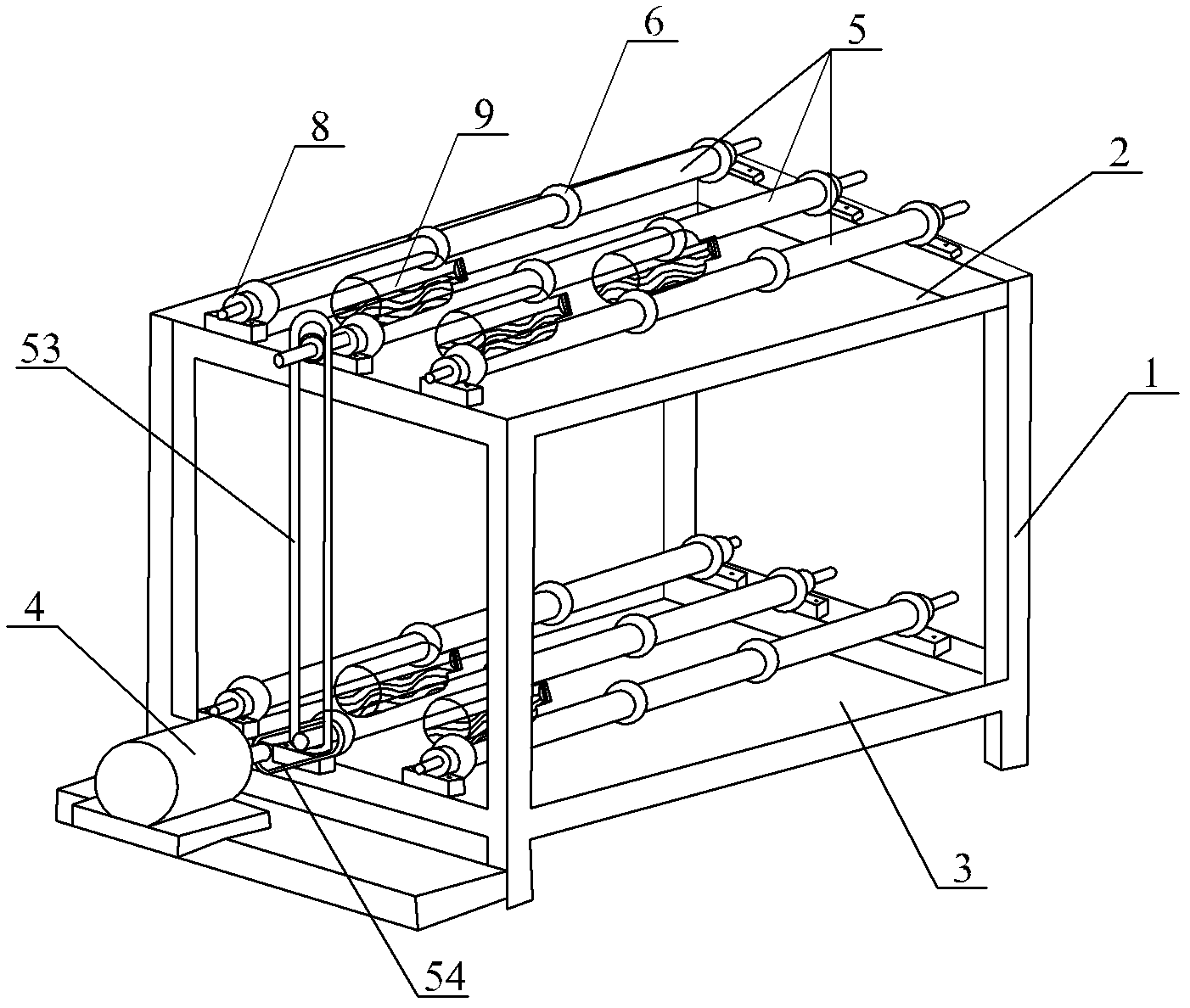

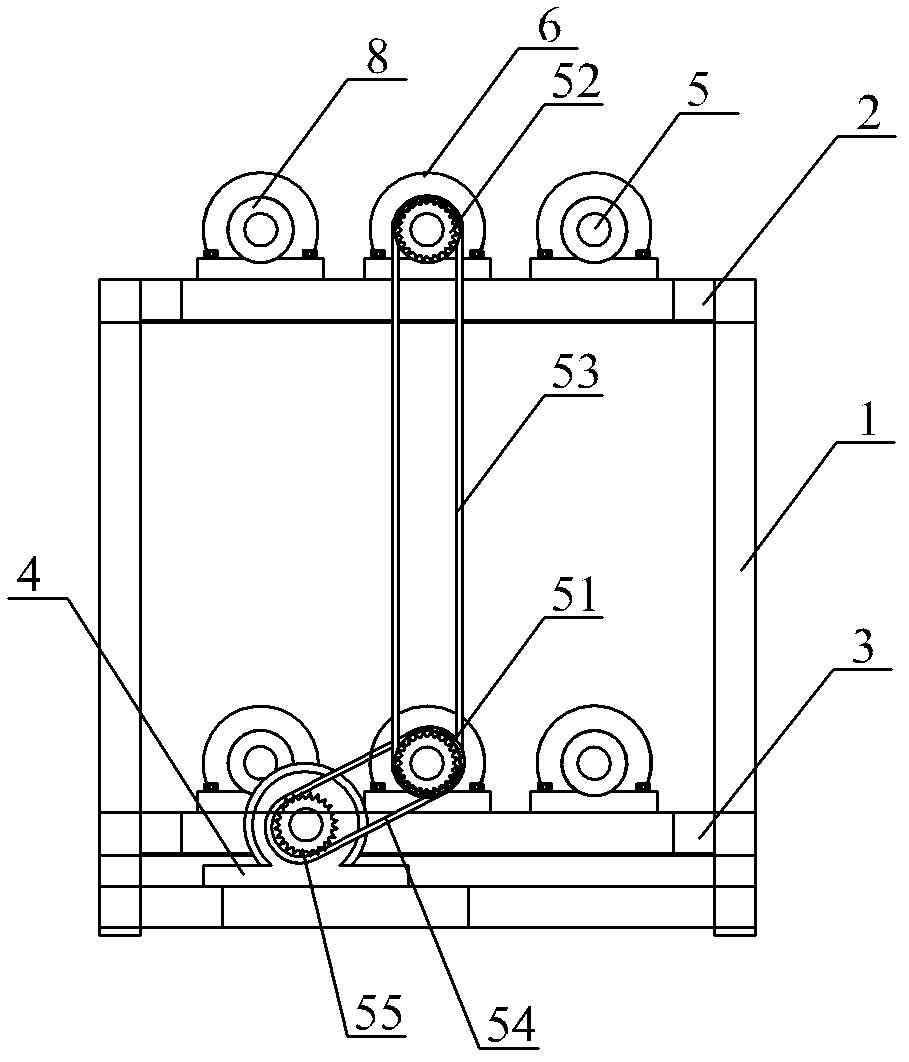

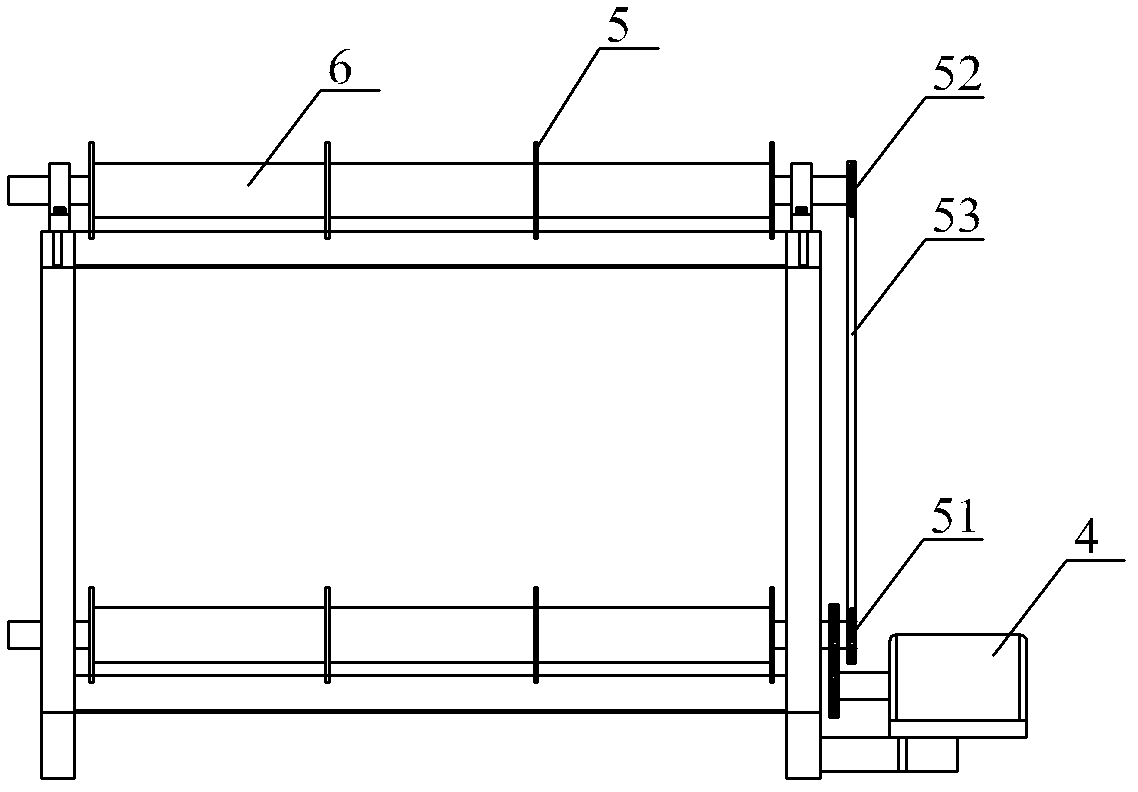

[0022] The paint preparation equipment for organic photosensitive drum coating as shown in the figure is composed of a ball mill and a filter system for paint filtration. Such as Figure 1-4 The ball mill shown is composed of a frame 1 and upper and lower worktables 2 and 3 located on the frame. The speed regulating motor 4 is installed on the frame 1, and 3 motors are installed on the upper and lower worktables 2 and 3 Roller shafts 5 arranged in parallel, and a plurality of sheaths 6 are sheathed on the roller shafts 5 . Both ends of the upper and lower workbenches 2 and 3 are respectively provided with a horizontal adjustment groove 7, and the end of the roller is covered with a bearing 8, and the bearing 8 is connected with the workbench by a fixing bolt 18 running through the horizontal adjustment groove 7. The intermediate roller on the lower workbench 3 is equipped with gears 51, 56, the output shaft of the speed regulating motor is equipped with a gear 55, the interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com