Folded shed of transitional portion between two mutually hinged vehicles or folded shed of airplane passenger gangway ladder or airplane passenger boarding bridge

A technology for aircraft passengers and transition parts, which is applied in the direction of connecting vehicles, vehicle parts, aircraft parts, etc., can solve the problems of expensive materials and increased cost of folding materials, achieve high inherent stability and save folding materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

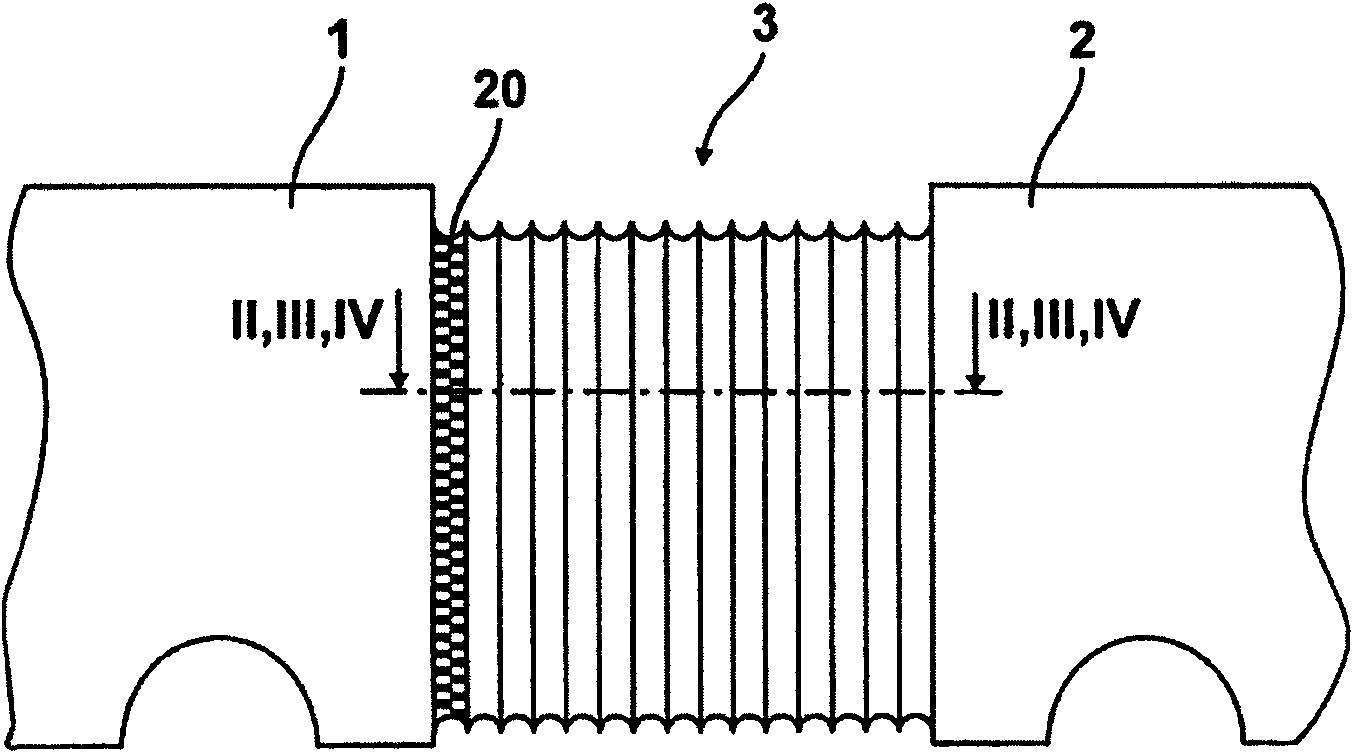

[0025] figure 1 Two vehicle components 1 and 2 are shown, which are connected to one another via a bellows 3 .

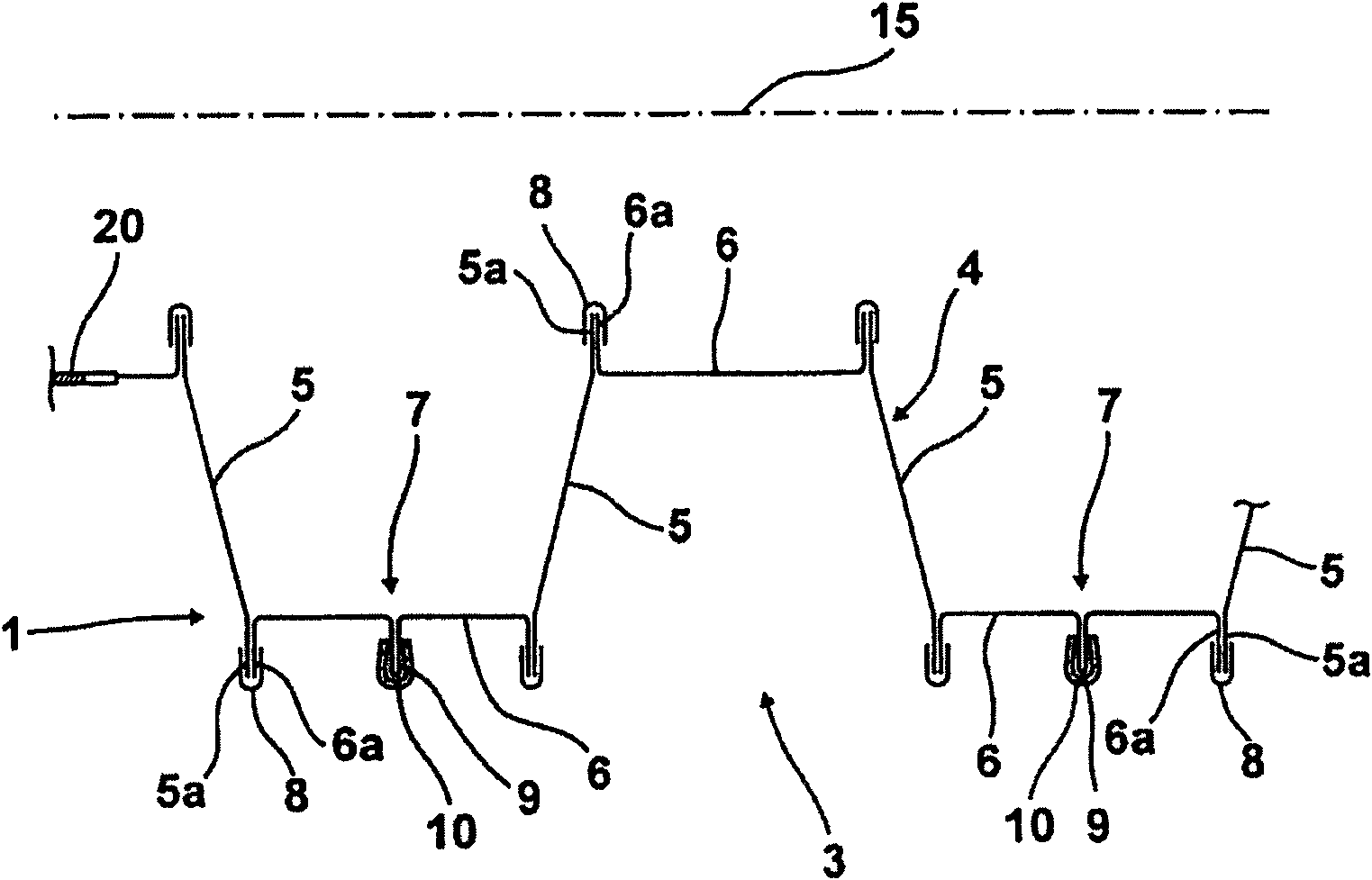

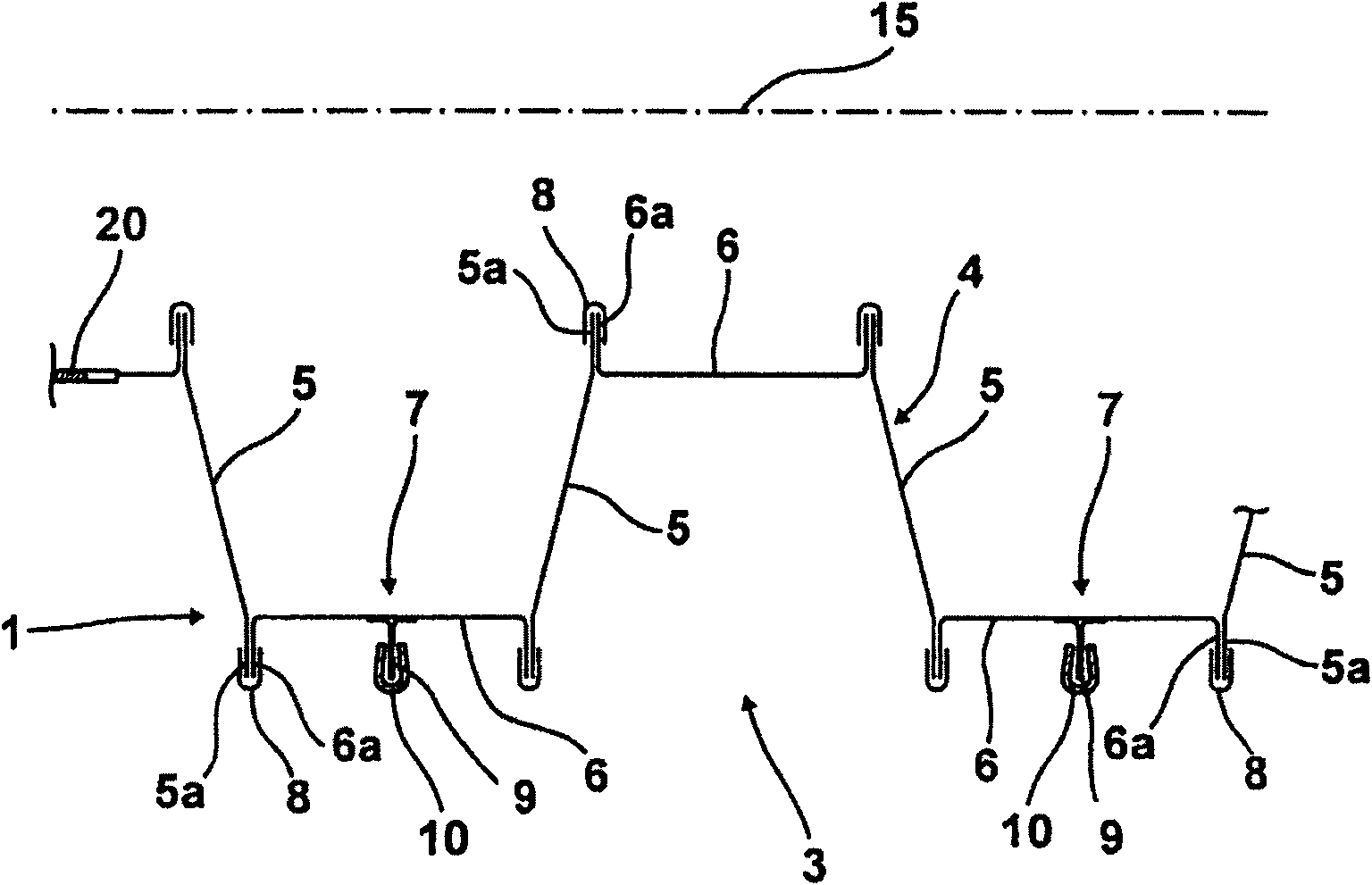

[0026] exist figure 2 and image 3 The bellows 3 shown in sectional view in , has pleats with the reference numeral 4 , wherein each pleat has two pleat legs 5 , wherein in the area of the pleat top 7 the two pleats The legs 5 are connected by connecting pieces 6 . The longitudinal center axis is referenced 15 .

[0027] The legs 5 and webs 6 of the folds each have a flange 5a, 6a on their sides facing each other, wherein in the region of the flanges a web 8 is arranged, which is U-shaped. Grab the two flanges 5a, 6a. The two flanges 5 a , 6 a are first glued and then sewn to the web 8 . The connecting web 6 , which is made of the same material as the folds, has a connecting element 9 approximately in the middle, the strip-shaped connecting element 9 being gripped in a clamping manner by the bellows frame denoted by reference numeral 10 . On the one hand, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap