Composite material explosion-proof box

A composite material and explosion-proof box technology is applied in the field of explosion-proof containers and high-strength composite material explosion-proof boxes, which can solve the problems of large volume and weight, explosion hazards in the upper and lower directions, and achieve the effects of small size, light weight and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

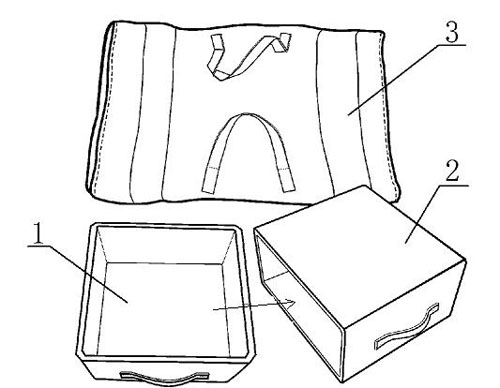

[0038] Example 1: A composite material explosion-proof box is composed of three parts: inner box 1, outer box 2 and parcel bag 3, see figure 1 shown.

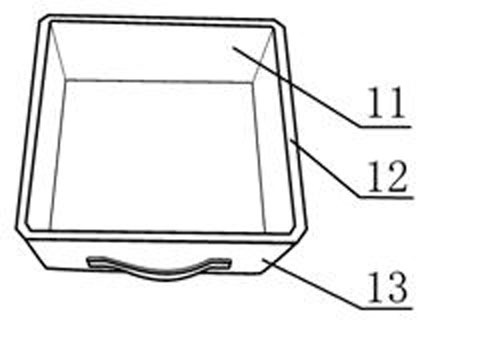

[0039] Wherein, the inner box 1 is a drawer-like structure, which adopts a box-shaped structure with an open upper end, and each wall of the inner box 1 is composed of three-layer structure, which are respectively the inner box flame-retardant layer 11 and the inner box main protective layer 12 from the inside to the outside. And inner box waterproof layer 13, refer to figure 2 shown.

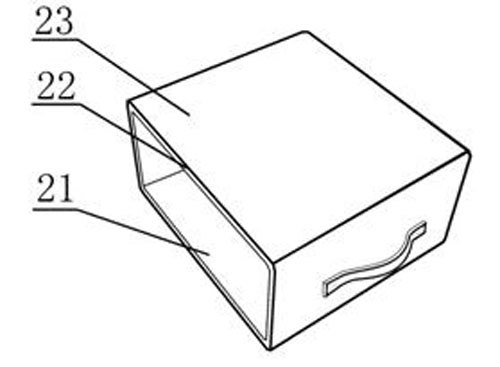

[0040] Wherein, the outer box 2 is a drawer-like structure, adopting a hexahedral box-shaped structure with side openings, and from the inside to the outside are the outer box flame-retardant layer 21, the outer box main protective layer 22, and the outer box waterproof layer 23, see image 3 shown.

[0041] Wherein, the wrapping bag 3 is a flexible cylindrical structure, which respectively includes a wrapping bag flame-retardant layer 31...

Embodiment 2

[0048] Example 2: The package bag 3 in the implementation example 1 is not changed, and the explosion impact bearing surfaces of the inner box 1 and the outer box 2 in the implementation example are strengthened. Specifically, the following measures are adopted: the bottom of the inner box 1 (not shown in the figure) is padded with a high-strength fiber board with the same shape and size as the bottom of the inner box 1, and the surface density of the high-strength fiber board is 8~10kg / m 2 ; On the inner wall (not shown) of the outer box 2 corresponding to the opening surface of the inner box 1, the high-strength fiber composite board with the same shape and size as the inner wall of the outer box 2 is compositely produced, and the surface density of the high-strength fiber composite board is 8~10kg / m 2 .

[0049] In this implementation example, 200g standard TNT explosives are placed in the geometric center of the inner case 1, then the inner case 1 is received into the...

Embodiment 3

[0051] Example 3: The inner box 1 in the implementation example 1 is not changed, and an electromagnetic shielding layer (not shown in the figure) is added to the exposed surfaces of the wrapping bag 3 and the outer box 2 in the implementation example. The electromagnetic shielding layer can use materials such as surface-coated film shielding materials, filled composite shielding materials, conductive coating-type shielding materials, or nanometer shielding materials.

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com