Novel dustproof rubber mat adopting splicing technology

A kind of rubber pad and technology, which is applied in the field of peripheral accessories of display modules of electronic products to achieve the effect of reducing waste and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

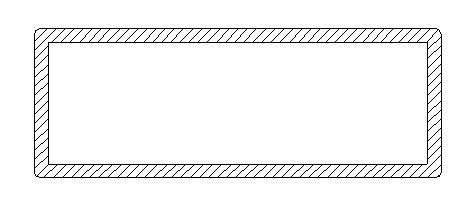

[0015] attached figure 1 It is a schematic diagram of the structure of the rubber pad in the prior art.

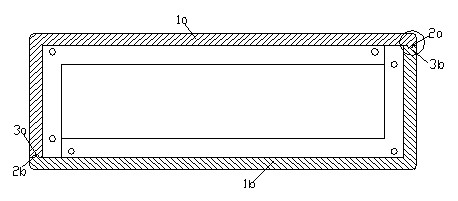

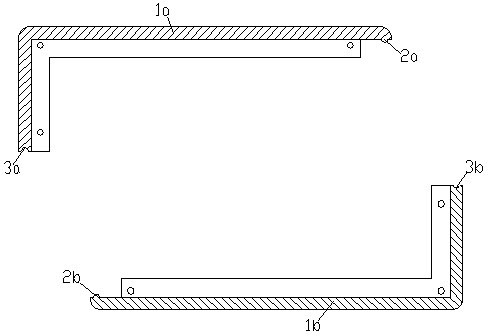

[0016] attached Figure 2-4 It is a dust-proof rubber pad of a new type of splicing technology according to the present invention, including a rubber pad body, which is made of polyurethane foam material; the rubber pad body is composed of two identical L-shaped unit blocks ; The two identical L-shaped unit blocks are the first L-shaped unit block 1a and the second L-shaped unit block 1b; the long end of the L-shaped unit block is provided with arc-shaped protrusions; the L-shaped unit block The short end is provided with a groove matching the arc-shaped protrusion; the arc-shaped protrusion 2a at the long end of the first L-shaped unit block is connected with the groove 3b at the short end of the second L-shaped unit block The groove 3a at the short end of the first L-shaped uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com