Chucking type pipe joint fitting

A clamping type and pipe head technology, which is applied in the direction of pipes/pipe joints/pipe fittings, through components, non-detachable pipe connections, etc., can solve the problem of easy damage and fracture of cylindrical connection parts, inconvenient connection, and affecting the normal transportation of pipelines, etc. problems, to achieve the effect of ensuring normal transportation, firm connection parts and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

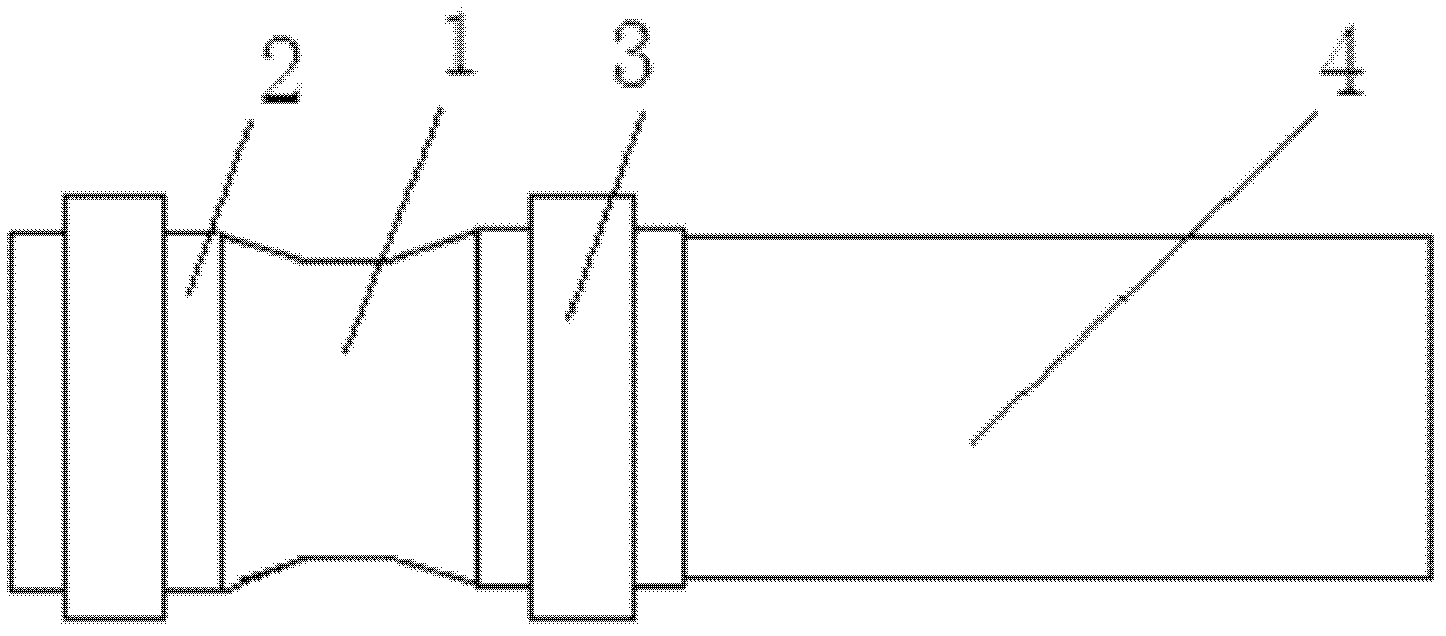

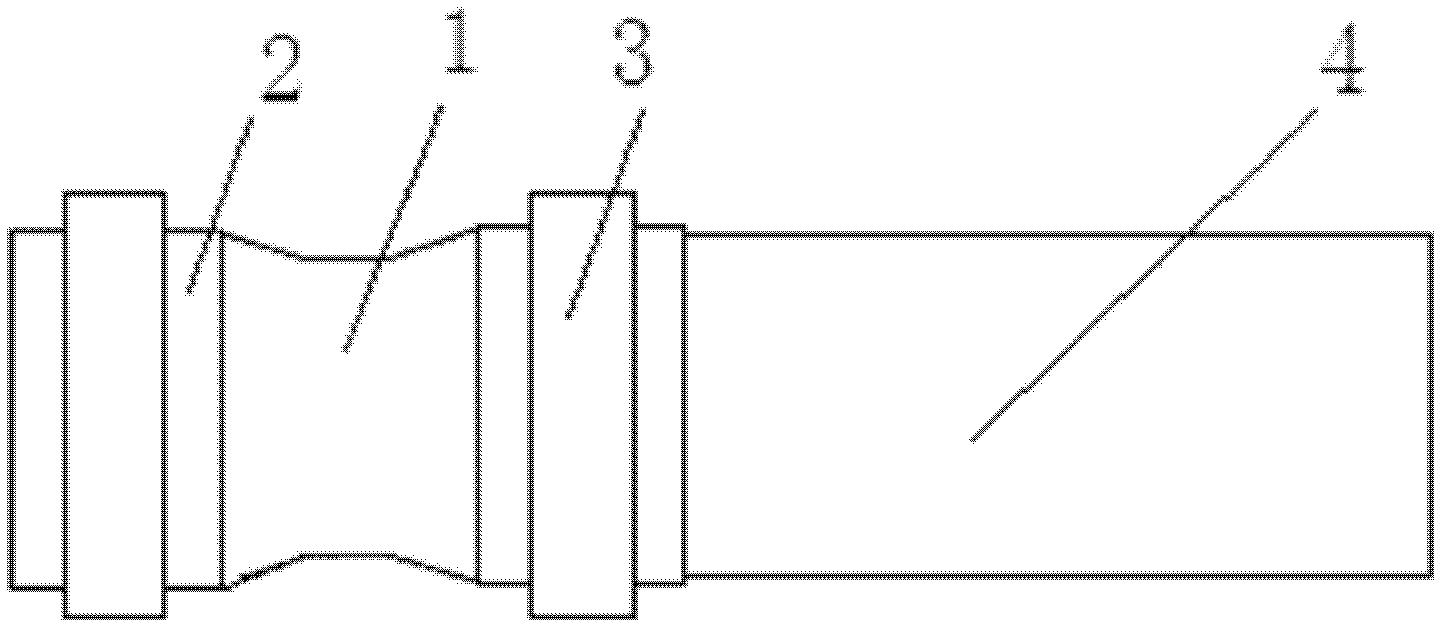

[0011] Such as figure 1 As shown, a clamping type pipe head fitting includes a pipe head body 1, a cylindrical connection part 2 and a clamping sleeve 3, and a cylindrical connection part 2 is provided on both sides of the pipe head body 1, and a cylindrical connection part The radius of 2 is greater than the radius of the pipe head body 1, and the clamping sleeve 3 is sleeved on the outside of the cylindrical connecting part 2. Internal threads are provided on the inner wall of the cylindrical connection part 2 . The cylindrical connection part 2 is made of stainless steel.

[0012] The present invention utilizes a pressing tool to squeeze the clamping sleeve 3, and through the clamping sleeve 3, the cylindrical connection part 2 of the pipe head fitting and the pipeline 4 are compressed and connected. The connection is very convenient, the work efficiency is improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com