Liquid crystal lens for three-dimensional display and manufacture method thereof

A technology of a liquid crystal lens and a manufacturing method, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems that the display does not meet the light, thin, short, and thick display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

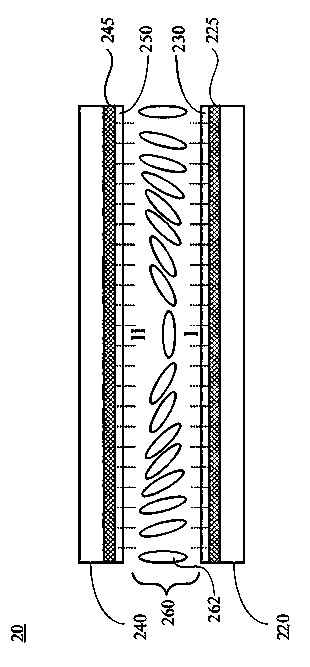

[0026] Please refer to figure 2 , figure 2 A schematic cross-sectional view of a liquid crystal lens for 3D display according to a preferred embodiment of the present invention is shown. The liquid crystal lens 20 in the figure is a schematic partial cross-sectional view of the 2D / 3D switching layer (not shown in the figure). The liquid crystal lens 20 includes a first substrate 220, a second substrate 240, a liquid crystal layer 260, a first electrode layer 225, a first alignment layer (alignment layer) 230, a second electrode layer 245 and a second Alignment layer 250.

[0027] Such as figure 2 As shown, the second substrate 240 is disposed corresponding to the first substrate 220 , and the liquid crystal layer 260 is disposed between the first substrate 220 and the second substrate 240 . The first substrate 220 and the second substrate 240 are glass substrates or flexible substrates. The first electrode layer 225 is disposed on a side of the first substrate 220 faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com