Self-locking type shutter device with high impact resistance

A high-impact, shutter technology, which is applied in shutters, optics, cameras, etc., can solve problems such as the expansion of the outer diameter of the imaging system, unsatisfactory opening and closing time, etc., to achieve reasonable space utilization, control trial production costs, and improve consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

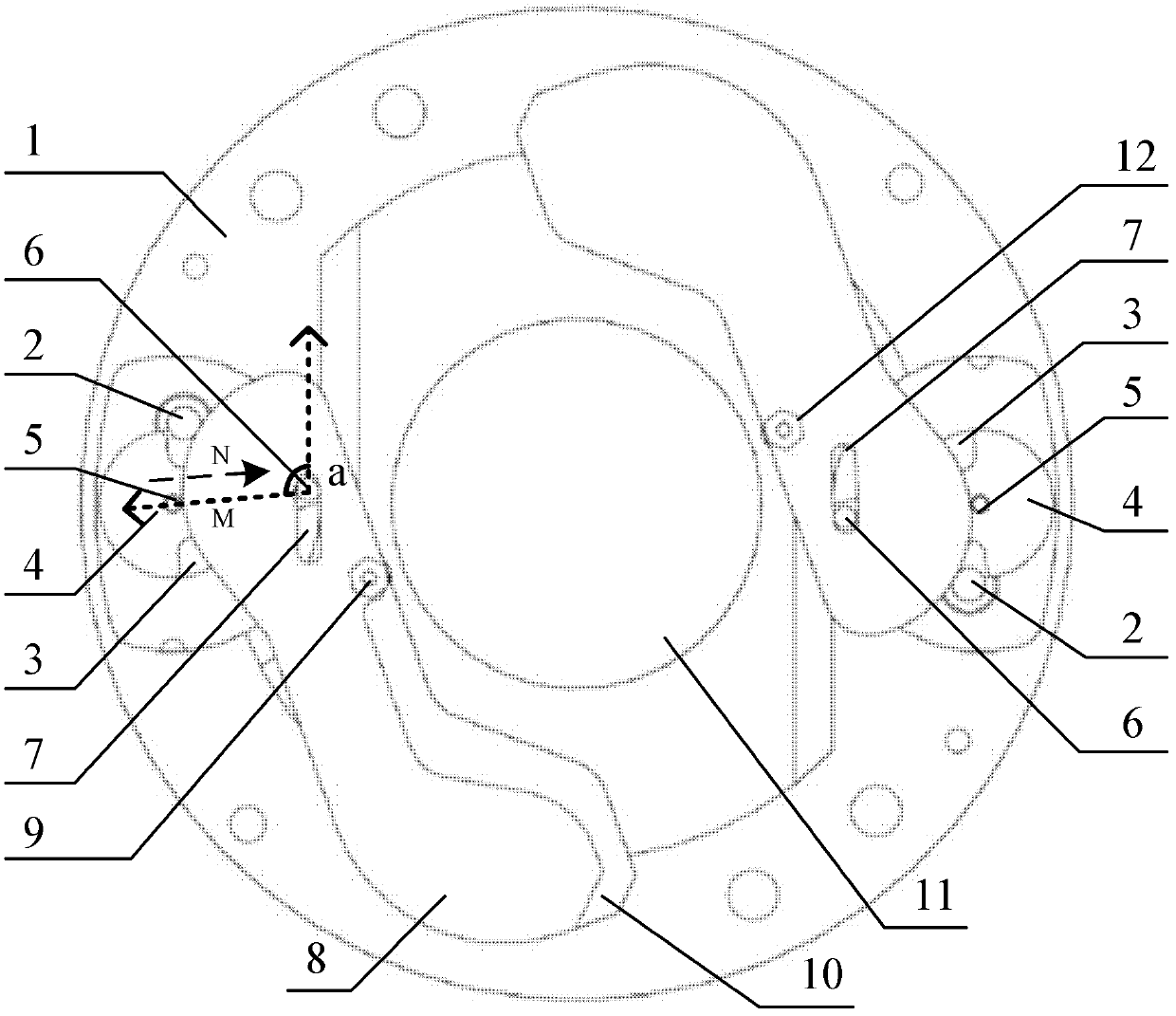

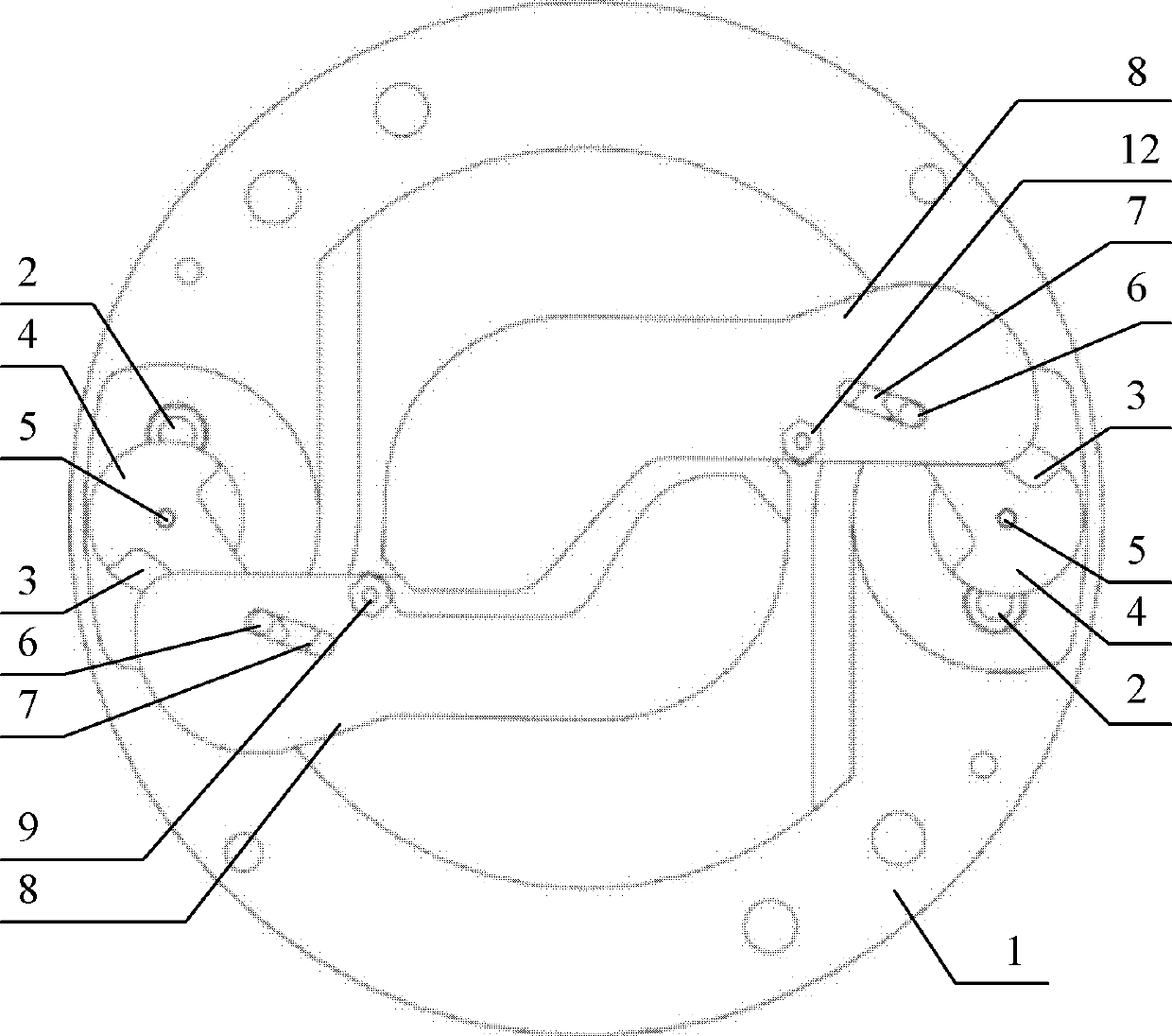

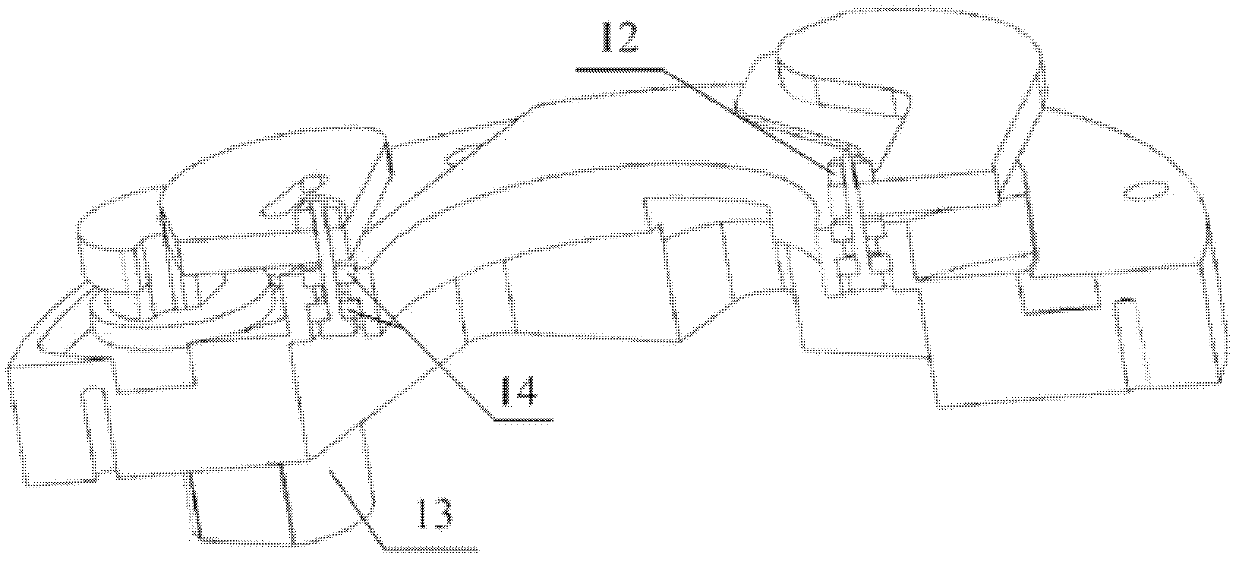

[0033] see Figure 1-3 As shown, a self-locking anti-high impact shutter device of the present invention mainly includes an image sensor bracket 1 , a blocking piece 8 , an actuating arm 4 and a driving motor 13 .

[0034] Wherein, a photosensitive window 11 is provided in the middle of the image sensor support 1 .

[0035] The shutter 8 is provided with a sliding groove 7, and is rotatably installed on the image sensor bracket 1 through the shutter shaft 9, completely covers the photosensitive window 11 when closed, and is located on both sides of the photosensitive window 11 and does not exceed the image sensor bracket when it is normally open. 1 range.

[0036] Preferably, the blocking plate 8 is approximately spoon-shaped as a whole, and can be specially designed according to the shape and size of the photosensitive window 11 and the sensor bracket 1 in actual use, and the sliding groove 7 is arranged at the proximal end of the spoon handle. A pair of micro-ball bearings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com