Printing unit structure capable of replacing adhered and hung printing offset plate under non-stop condition

A technology of printing unit and offset plate, which is applied in the general parts of printing machinery, printing, printing presses, etc., can solve the problems such as the inability to improve the work efficiency, the inability to improve the utilization rate of equipment, and the inability to rotate independently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

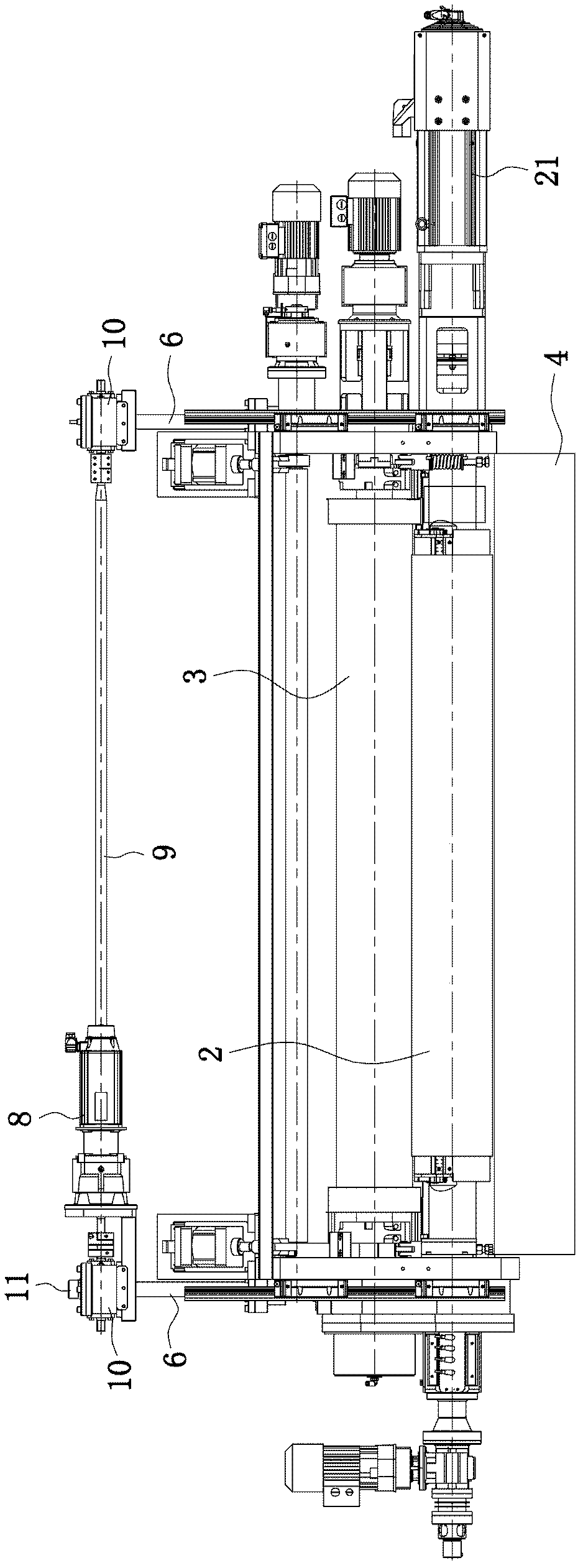

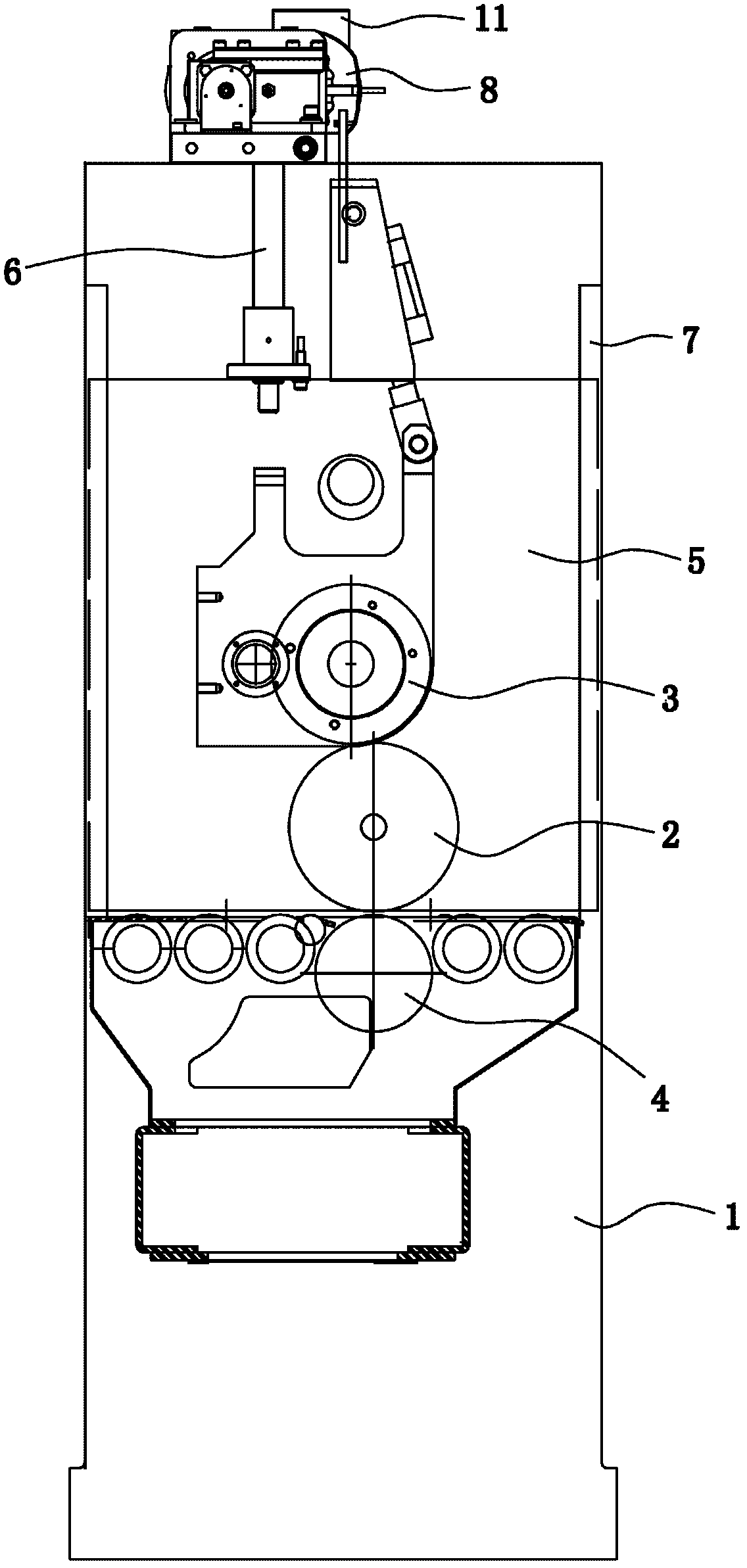

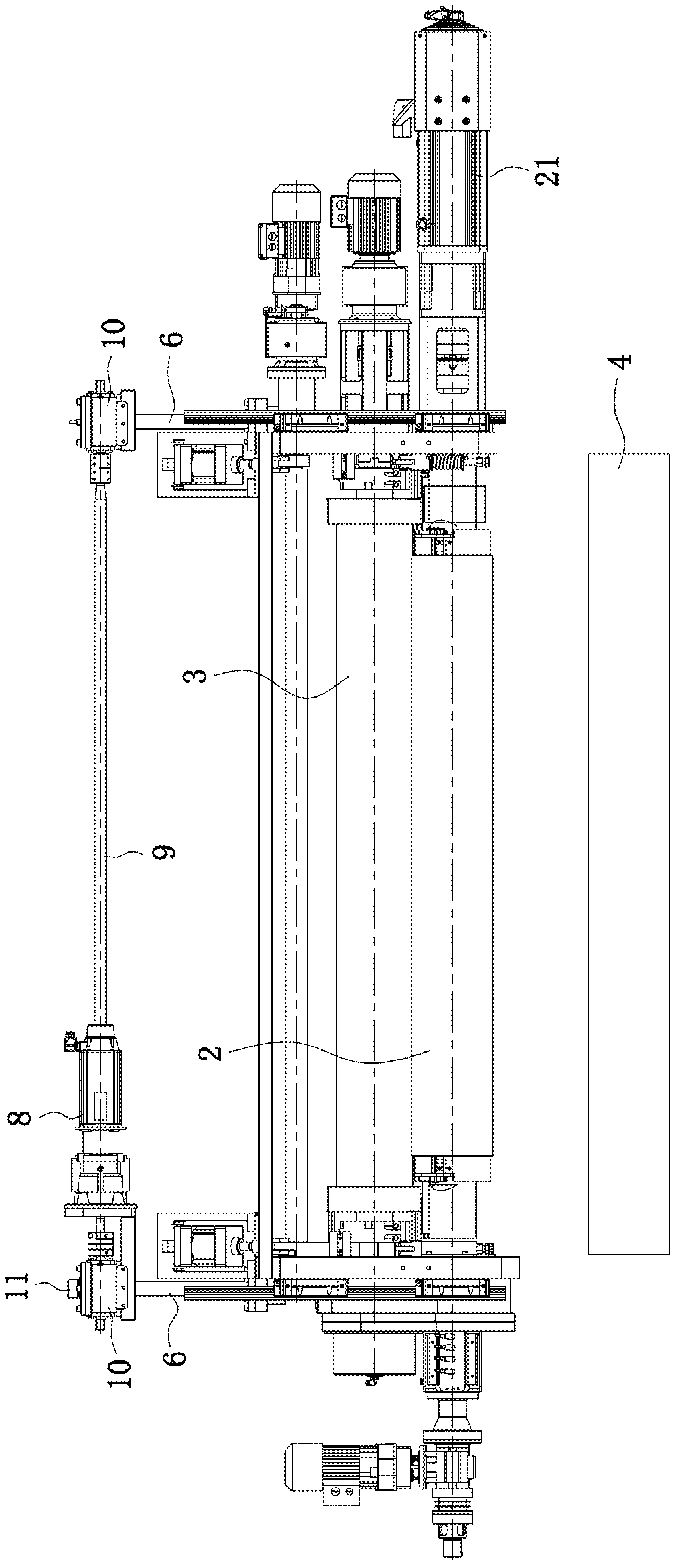

[0013] Below in conjunction with accompanying drawing, the utility patent is further described.

[0014] In this embodiment, the printing unit structure for replacing the stuck printing offset plate without stopping the machine includes a frame 1, a printing roller 2, an inking roller 3 and an embossing roller 4, and the embossing roller 4 is installed on the frame 1 It cannot be moved up and down. The printing roller 2 is respectively pressed with the inking roller 3 and the embossing roller 4. There is a lifting device on the frame 1, and the inking roller 3 and the printing roller 2 are installed on the On the lifting device; the printing registration servo motor 21 is set on the device that drives the printing roller 2 to rotate, so that the printing roller 2 on the embossing unit that is lowered to the printing height rotates and registers the printing position on the cardboard, and the lifting device is controlled by the slide The block 5 and the lead screw 6 are compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com