Corner pad and its panel

A technology of cover corners and plates, applied in flexible coverings, closures, packaging, etc., can solve problems such as the decrease in the strength of the cover corner structure, the inability to exert the effect of the clamping structure, and the damage of the cover corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

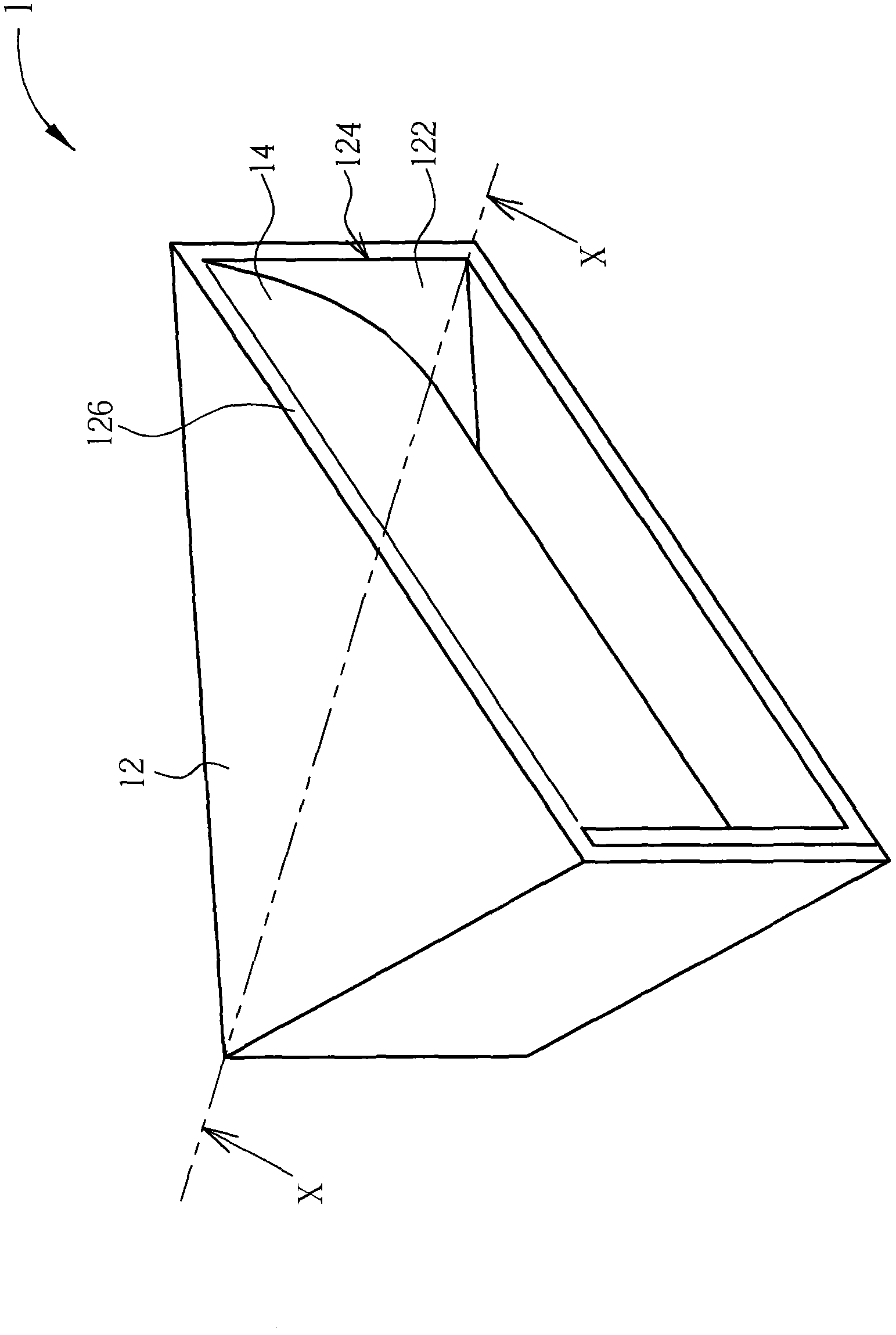

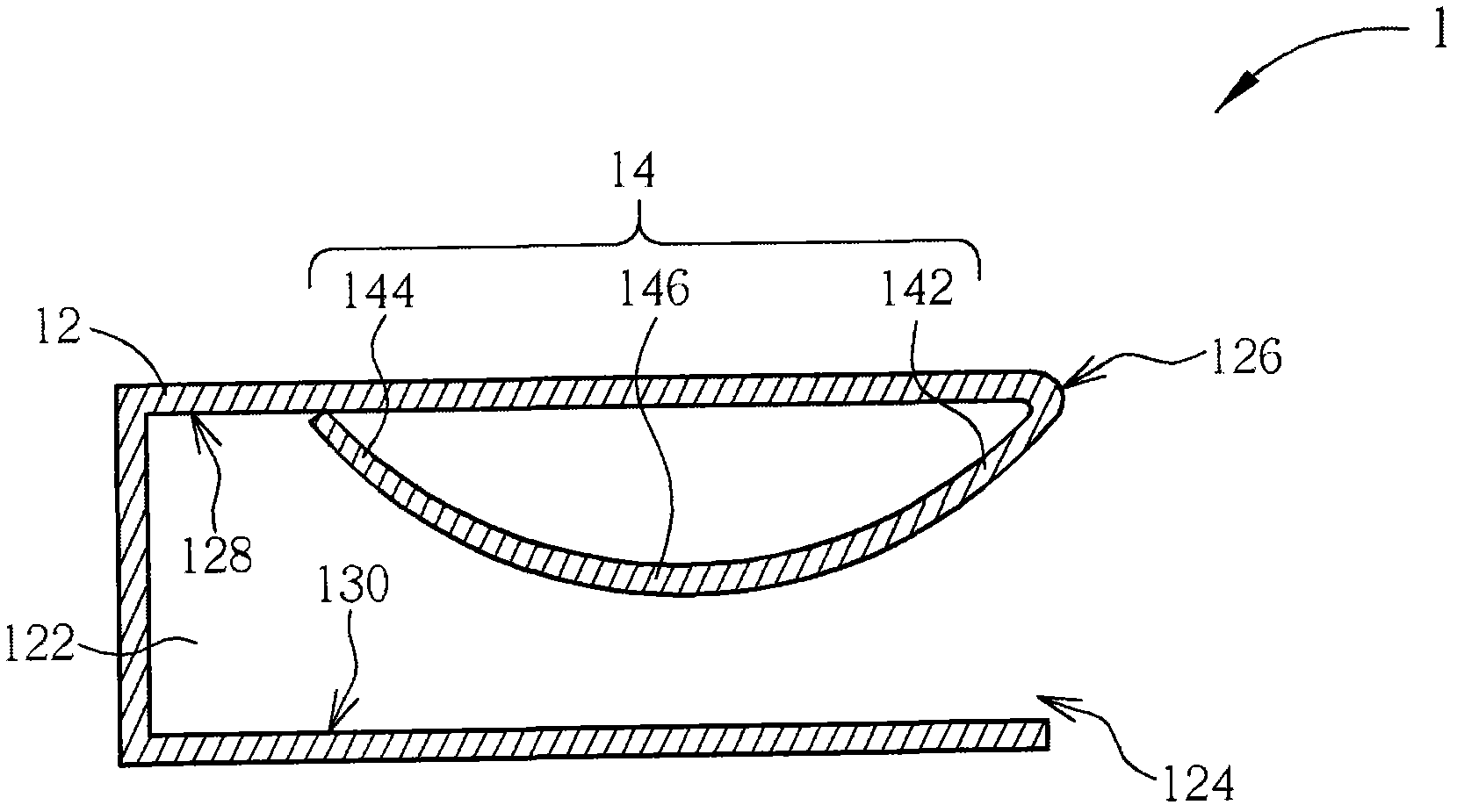

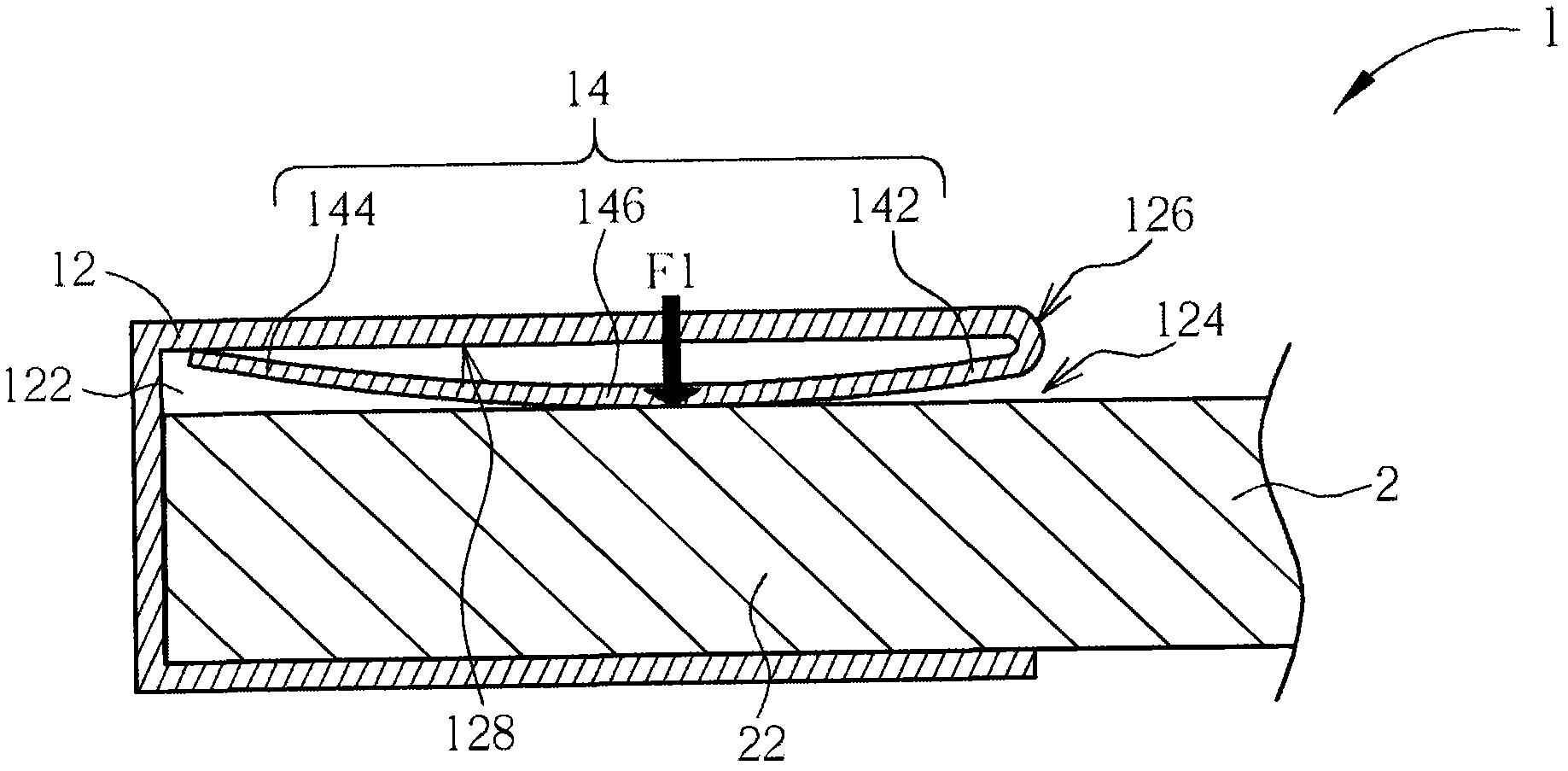

[0038] see figure 1 and figure 2 , figure 1 It is a schematic diagram of a set of corners 1 according to a preferred embodiment of the present invention, figure 2 is set angle 1 edge figure 1 Sectional view of midline X-X. The sleeve angle 1 includes a body 12 and a first curved elastic structure 14 . The main body 12 can have an accommodating space 122 , an opening 124 communicating with the accommodating space 122 , and an edge 126 at the opening 124 . The first curved elastic piece structure 14 has a first fixed end portion 142 and a first free end portion 144, the first curved elastic piece structure 14 is arranged in the accommodation space 122, the first fixed end portion 142 is fixed on the body 12, and In this embodiment, the first curved elastic structure 14 is formed by extending from the edge 126 ; in practice, the first curved elastic structure 14 can also be an independent object, which is fixed on the body 12 by another adhesive method. The first free end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap