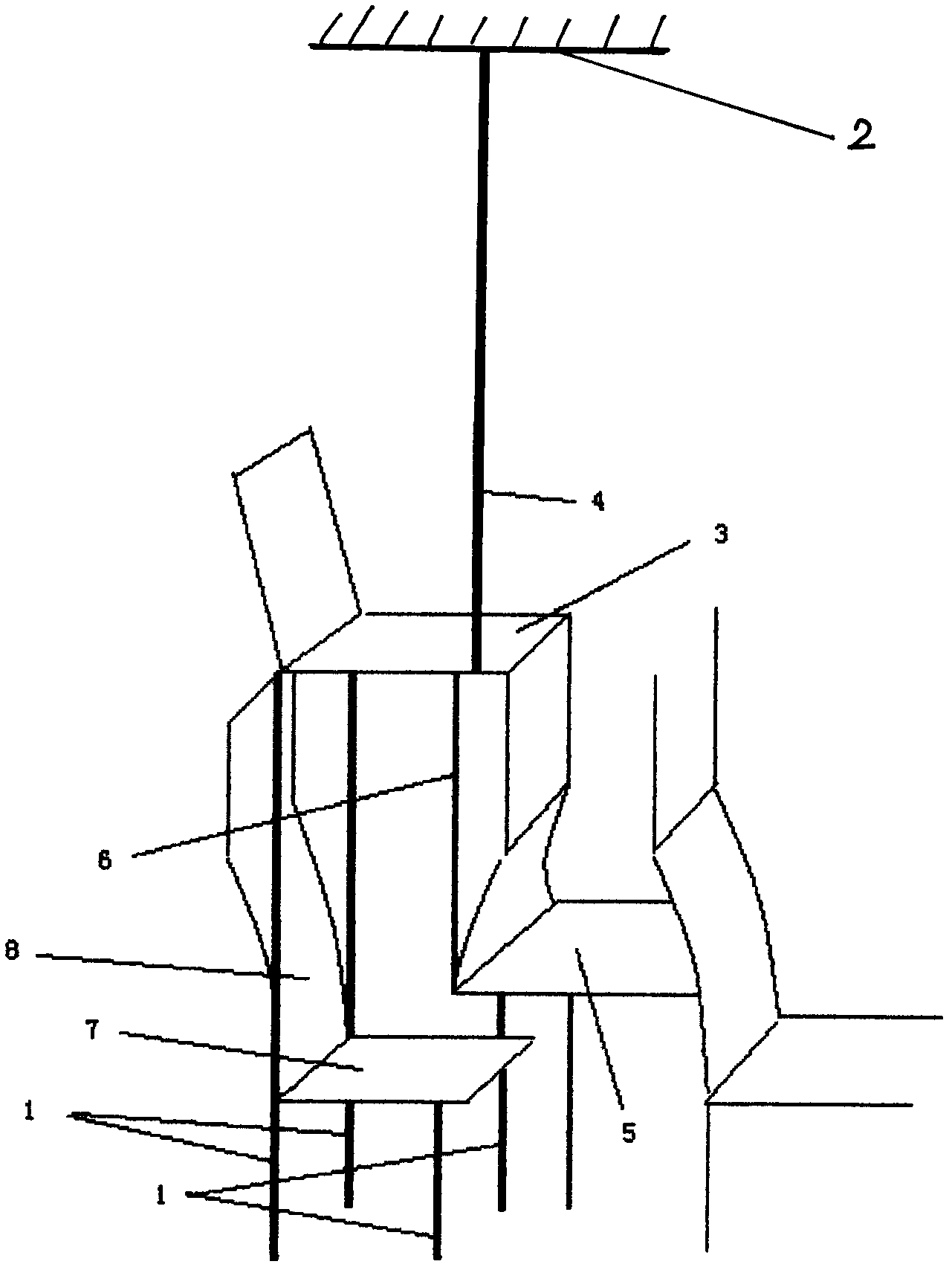

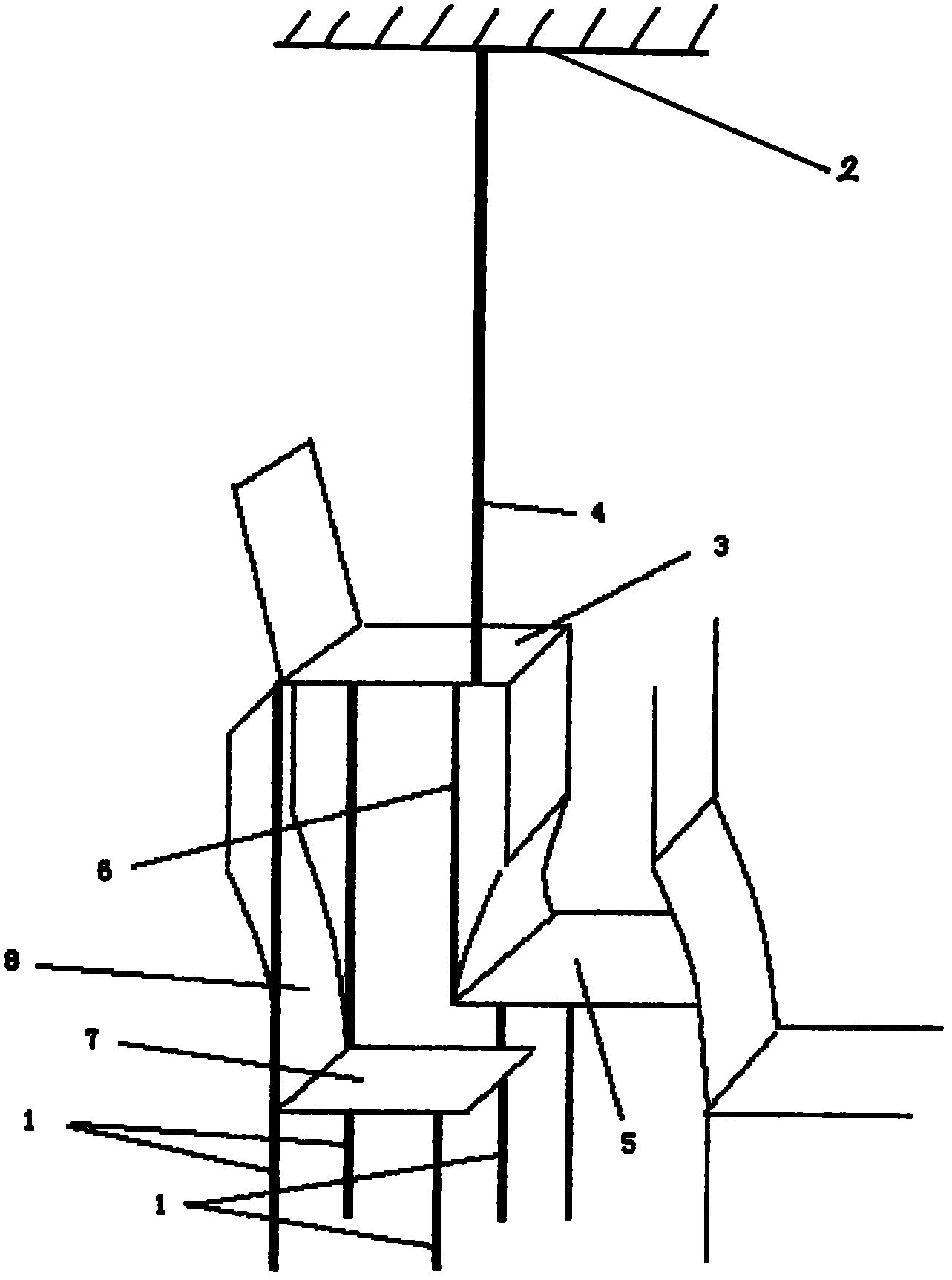

Seat installed in cavity

A seat and cavity technology, which is applied to vehicle seats, transportation and packaging, special positions of vehicles, etc., can solve the problem that the seat space does not play its due role, so as to increase the number of passengers and increase the number of seats Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Choose strong metal materials to make four supporting legs, three long and one short, and fix the four corners of the lower seat seat board on the four supporting legs respectively, so that the shortest supporting leg is under the seat board on the passenger side. In the front position, fix the four supporting legs on the passenger car, and then connect the three corners of the upper seat board with the three longer supporting legs. At the upper line position of the required height, a support leg pointing upwards is fixed at the front position of the passenger seat side of the upper seat seat plate, and its upper end is fixed on the top of the compartment. Finally, install the footboard above the lower seat in front of the upper seat. The surface of the footboard is rectangular. Keep a certain distance between the footboard and the backrest of the lower seat. The upper supporting leg is fixedly connected with the upper seat board at its upper end. The remaining three c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com