Continuous wire feed tube constrained wire explosion spraying device

A technology of wire feeding tube and conveyor belt, which is applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of limited application, electrode ablation, and cumbersome operation process, so as to improve efficiency and avoid electrode burning Corrosion, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

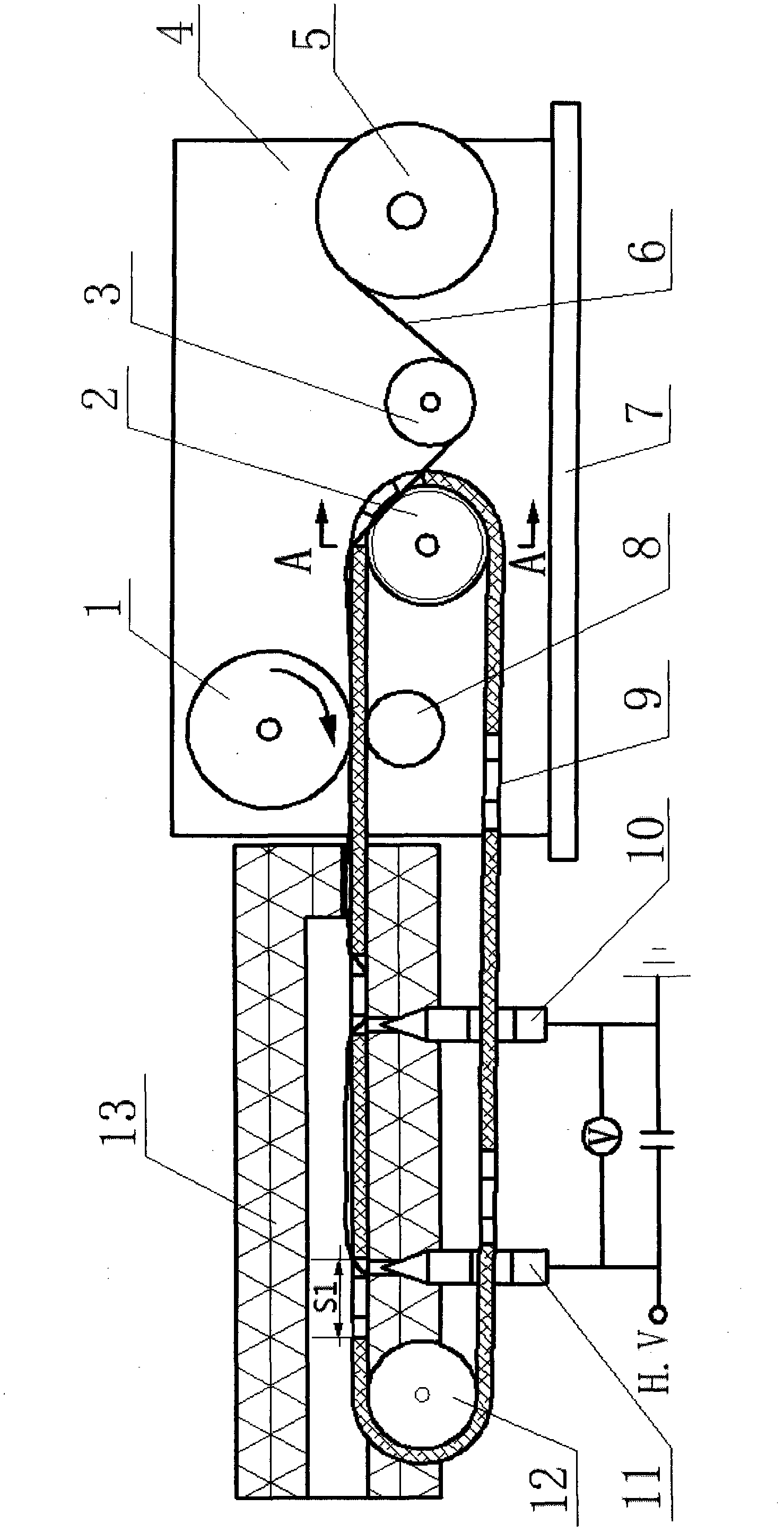

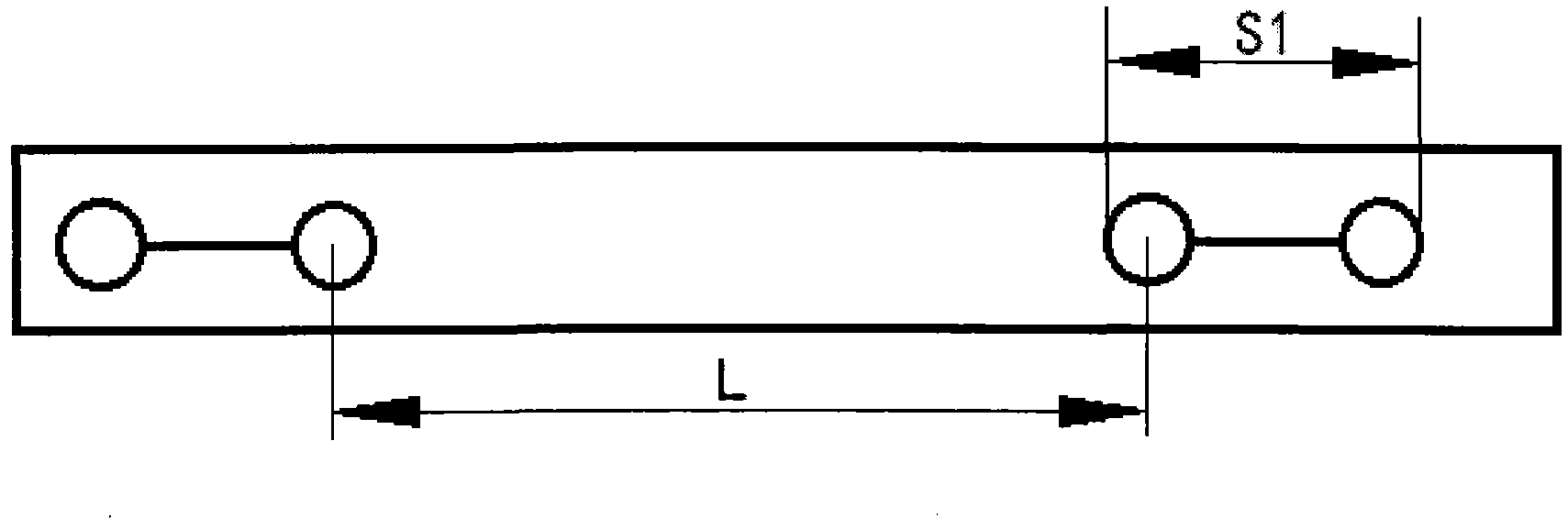

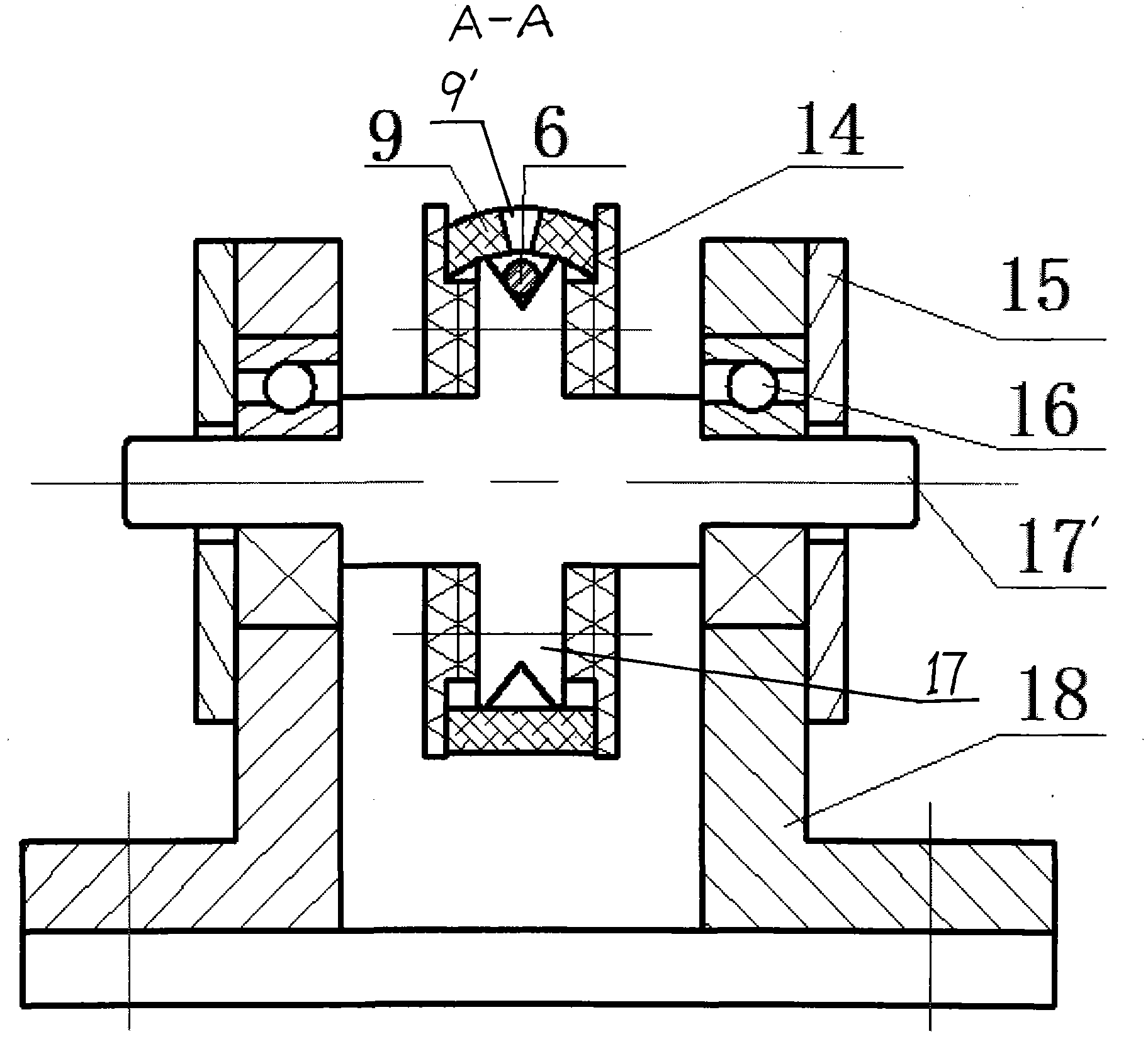

[0009] Such as figure 1 , image 3 As shown, the present invention is a continuous wire feeding tube constrained electric explosion spraying device. The conveyor belt 9 is driven by a drive wheel 1 and a pinch wheel 8. It is driven by a top belt mechanism 2 and a driven wheel 12. The spray chamber is a U-shaped structure. , the high-voltage electrode 11 and the low-voltage electrode 10 are set on the same straight line in the lower semicircle of the spray gun 13, the low-voltage electrode 10 is connected with the low-voltage end of the capacitor, the high-voltage electrode 11 is connected with the high-voltage end of the capacitor, and the two poles of the capacitor are connected with the high-voltage generator H.V. Top belt mechanism 2 is made up of two stoppers 14 and top pulley 17, and two stoppers 14 and top pulley 17 are coaxial, symmetrical to top pulley 17 and are installed on the rotating shaft 17 ' of top pulley, and rotating shaft 17' is fixed on the bearing 16, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com