A deep-sea high-power capacitive load DC contact protector

A capacitive load and contact protection technology, applied in relays, electrical components, circuits, etc., can solve the problems of wasting manpower, material and financial resources, high operating costs of deep-sea equipment, and prone to failure, so as to improve the service life and protect itself Equipment safety, effects of avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

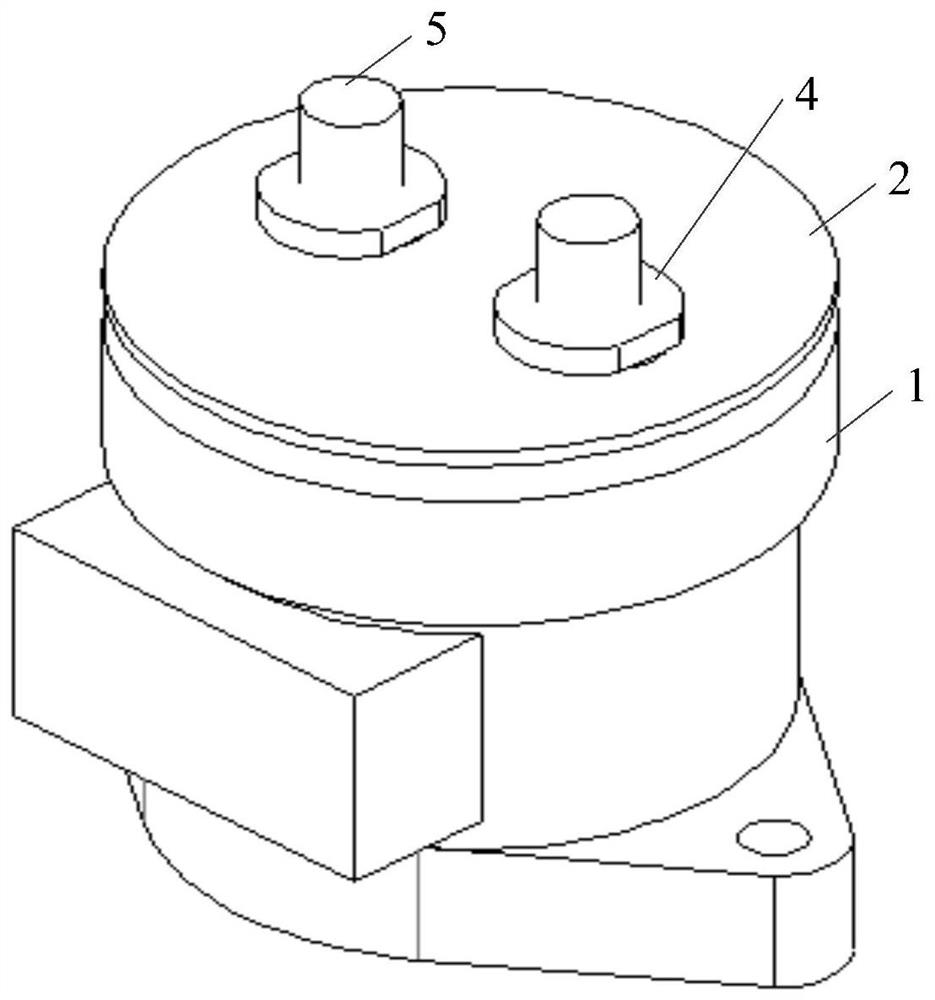

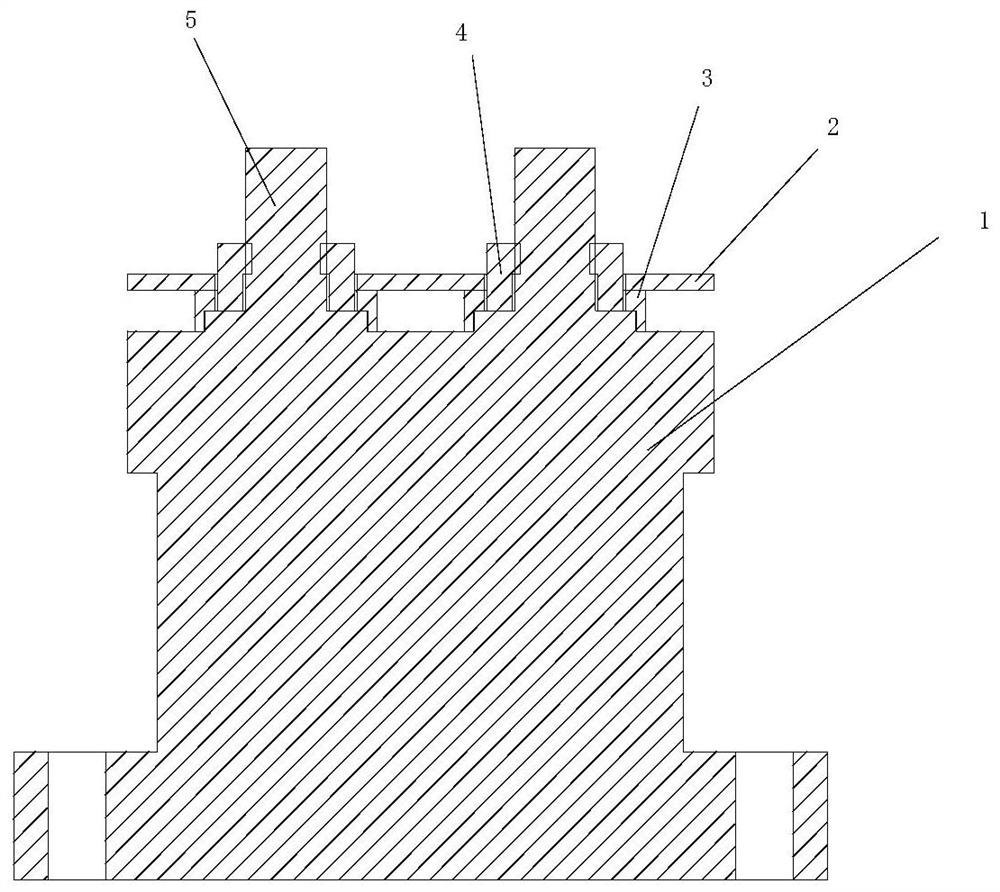

[0022] The embodiment of the present invention provides a deep-sea high-power capacitive load DC contact protector, combined with reference figure 1 with figure 2 , a deep-sea high-power capacitive load DC contact protector, characterized in that it includes: a contactor switch 1, a delay bypass circuit 2, a gasket 3 and a waist-shaped copper sleeve 4; the wiring copper column 5 of the contactor switch 1 passes through the gasket 3 and the waist-shaped copper sleeve 4 are connected and fixed with the delay bypass circuit 2.

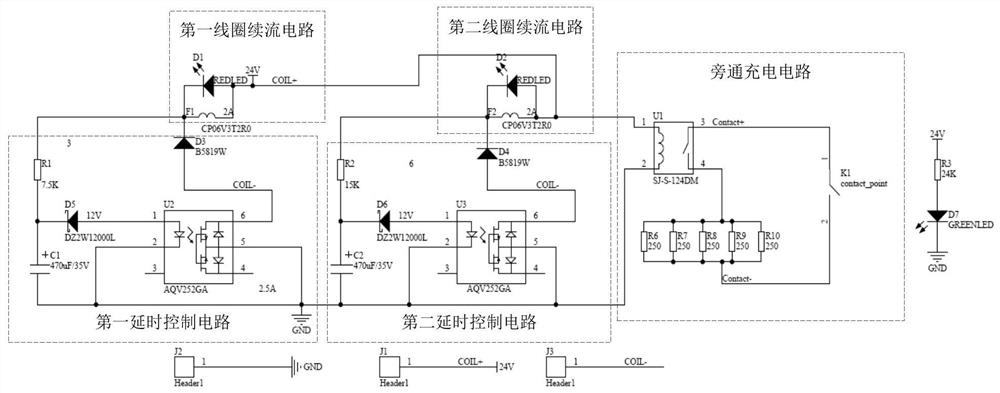

[0023] The delay bypass circuit 2 is used to slowly charge the capacitive load to the power supply voltage within a few seconds before the contact of the contactor switch 1 is turned on; the washer 3 is used to support the delay bypass circuit 2; the waist-shaped copper The sleeve 4 is used to conduct the large curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com