Steam iron comprising a soleplate including at least one first group and one second group of steam outlet holes

A technology of discharge holes and ironing boards, which is applied in the directions of hand irons, household appliances, textiles and papermaking, etc., can solve the problems of large volume and high implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

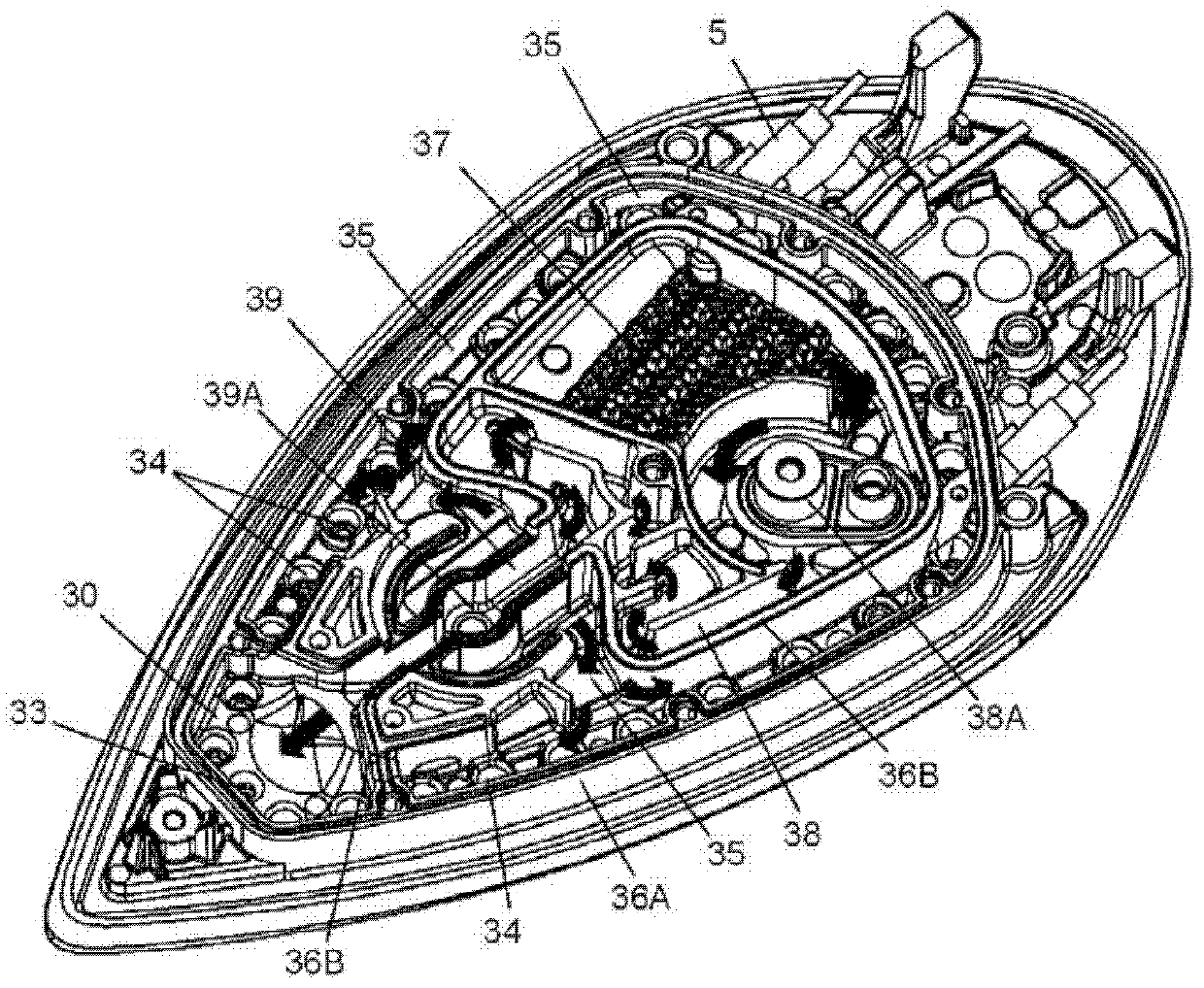

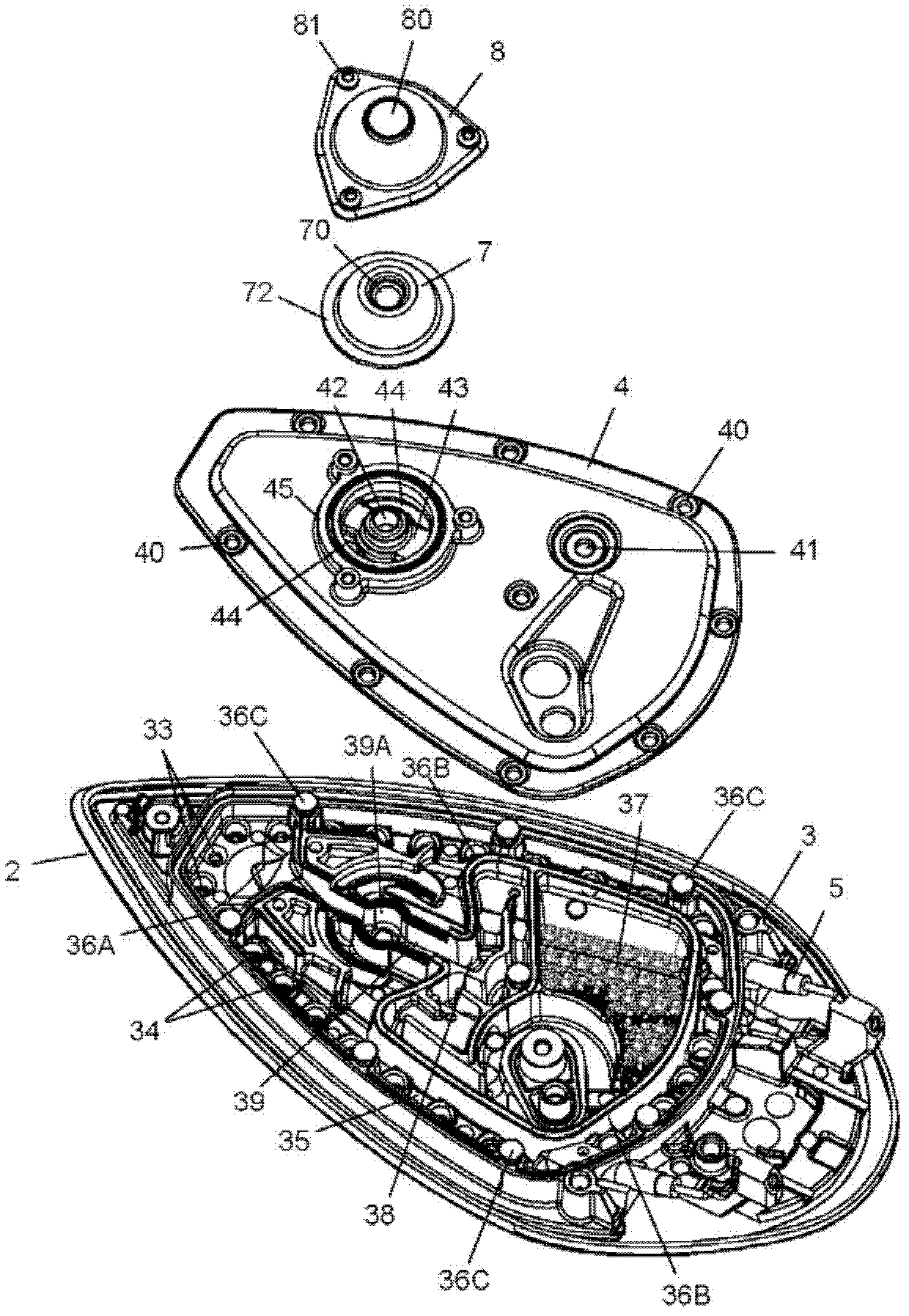

[0026] Only elements necessary for understanding the invention are shown. In order to facilitate reading of the drawings, the same elements in different drawings are marked with the same reference signs.

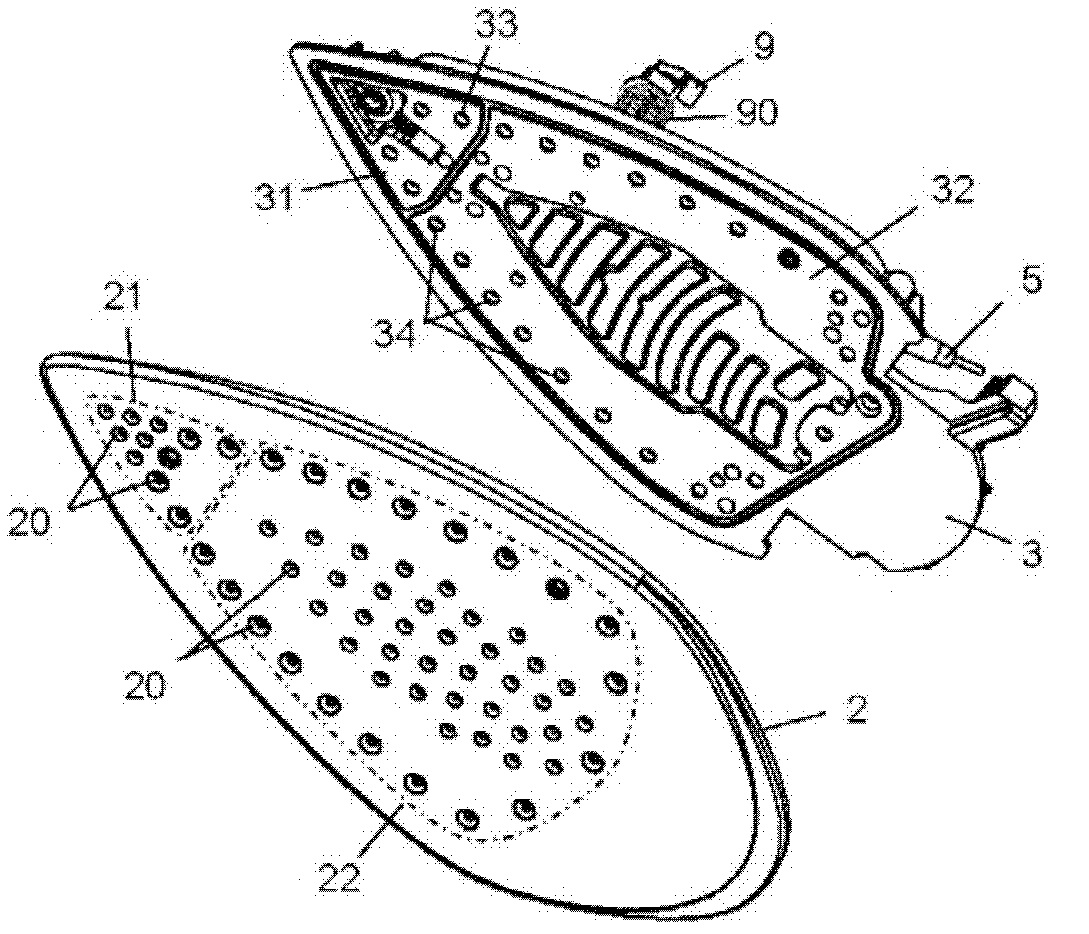

[0027] figure 1 Shown is an ironing appliance comprising a steam iron 1 placed on a sloping base of a steam generator housing 100 which, in a manner known per se, encloses a tank for generating pressurized steam, said The box is connected to the iron by a cable 101 .

[0028] according to figure 2 , said iron 1 comprises an ironing plate 2 in thermal contact with a heating soleplate 3 covered by a main body 10 of plastic material comprising a grip handle 11, the main body 10 of which is screwed (not shown) It is fixed on the sole plate 3 of the iron.

[0029] As an example, the ironing board 2 is made of an aluminum plate whose lower surface is in contact with the clothes to be ironed, the lower surface is covered with enamel, the heating soleplate 3 is realized in alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com