Mechanical sealing structure suitable for compressor

A mechanical seal and compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of large compressor vibration, small installation size, and small space size of the sealing cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

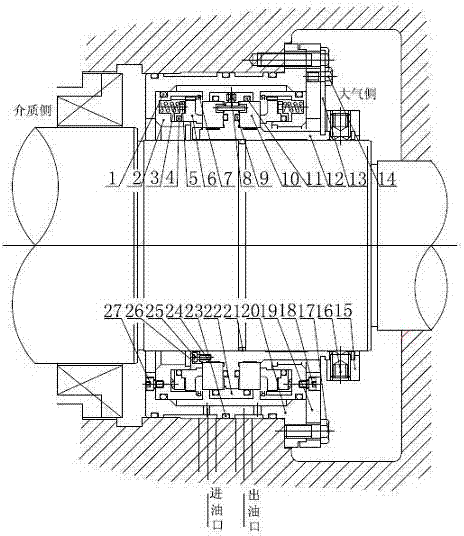

[0010] like figure 1 As shown, it is suitable for the mechanical seal structure of the compressor, the first O-ring 1, the transmission sleeve 2, the spring 3, the second O-ring 4, the push ring 5, the compensation ring 6, the snap ring 7, and the first jacking screw 8 , the third O-ring 9, the rotating ring 10, the fourth O-ring 11, the shaft sleeve 12, the positioning piece 13, the first bolt 14, the driving ring 15, the second jacking screw 16, the second bolt 17, the first inner Hex screw 18, end cover 19, sealing cavity 20, fifth O-ring 21, fastening sleeve 22, sixth O-ring 23, corrugated belt 24, second hexagon socket screw 25, pressure plate 26, third internal hexagon Screws 27, the first O-ring 1 and spring 3 are put into the drive sleeve 2, the second O-ring 4 is put into the push ring 5, after assembly, put into the drive sleeve 2, and then into the compensation ring 6 and snap ring 7, above The compensation mechanism on the medium side is assembled, and the compens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com