Wear-resistant rubber belt with lip edge

A wear-resistant rubber and rubber belt technology, which is applied to vehicles, conveyors, transportation and packaging with endless chains/belts. problems, to achieve the effect of high reliability of sealing action, automatic compensation of gap allowance and wear allowance, and reduction of manufacturing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

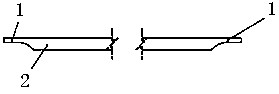

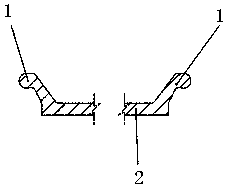

[0021] see Figures 1 to 4 It is a structural view, a cross-sectional view, a cross-sectional view of the replacement rubber belt, and a cross-sectional view of the working state of the present invention. It includes a conveyor belt main body. Two lip structures are respectively connected to both sides of the conveyor belt main body. Composed of rubber, the lip structure is composed of edge-sealing wear-resistant rubber and several aggregate layers. The outer upper and lower ends of some aggregate layers are provided with surface rubber, and the outer edges of both ends of several aggregate layers are edge-sealed. Wear-resistant rubber coating, the surface rubber arranged at the upper end of several aggregate layers is arranged between the edge-sealed wear-resistant rubber on both sides, and the surface rubber arranged at the lower end of several aggregate layers is arranged between the edge-sealed wear-resistant rubber at both sides Between, the adjacent wear-resistant rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com