Method and equipment for obtaining base plates

A technology of substrates and equipment, applied in the field of obtaining substrates, can solve the problems of long movement distance, lower production efficiency, and increase the time loss of obtaining substrates, etc., to achieve the effects of shortening the movement distance, improving production efficiency, and reducing time loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

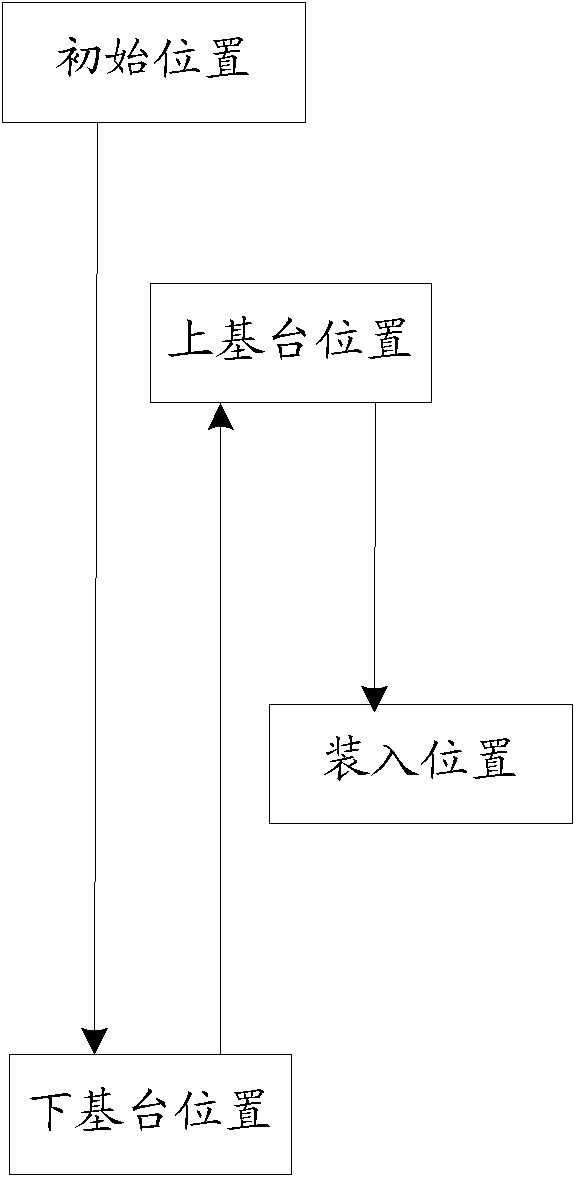

[0054] In this embodiment, the control device controls the specific actions of the grabbing device according to time detection, such as Figure 5 shown, including the following steps:

[0055] S501: The grasping device moves from the initial position to the position of the upper base according to the first control instruction sent by the control device, and acquires the upper substrate on the upper base;

[0056] S502: After the interval between sending the first control instruction reaches the preset first time, the control device sends a second control instruction to the grabbing device, and the grabbing device starts from the base station according to the second control instruction The position is moved to the position of the lower abutment, and the lower substrate on the lower abutment is obtained;

[0057] S503: After the interval between sending the second control instruction reaches the second preset time, the control device sends a third control instruction to the gra...

Embodiment 2

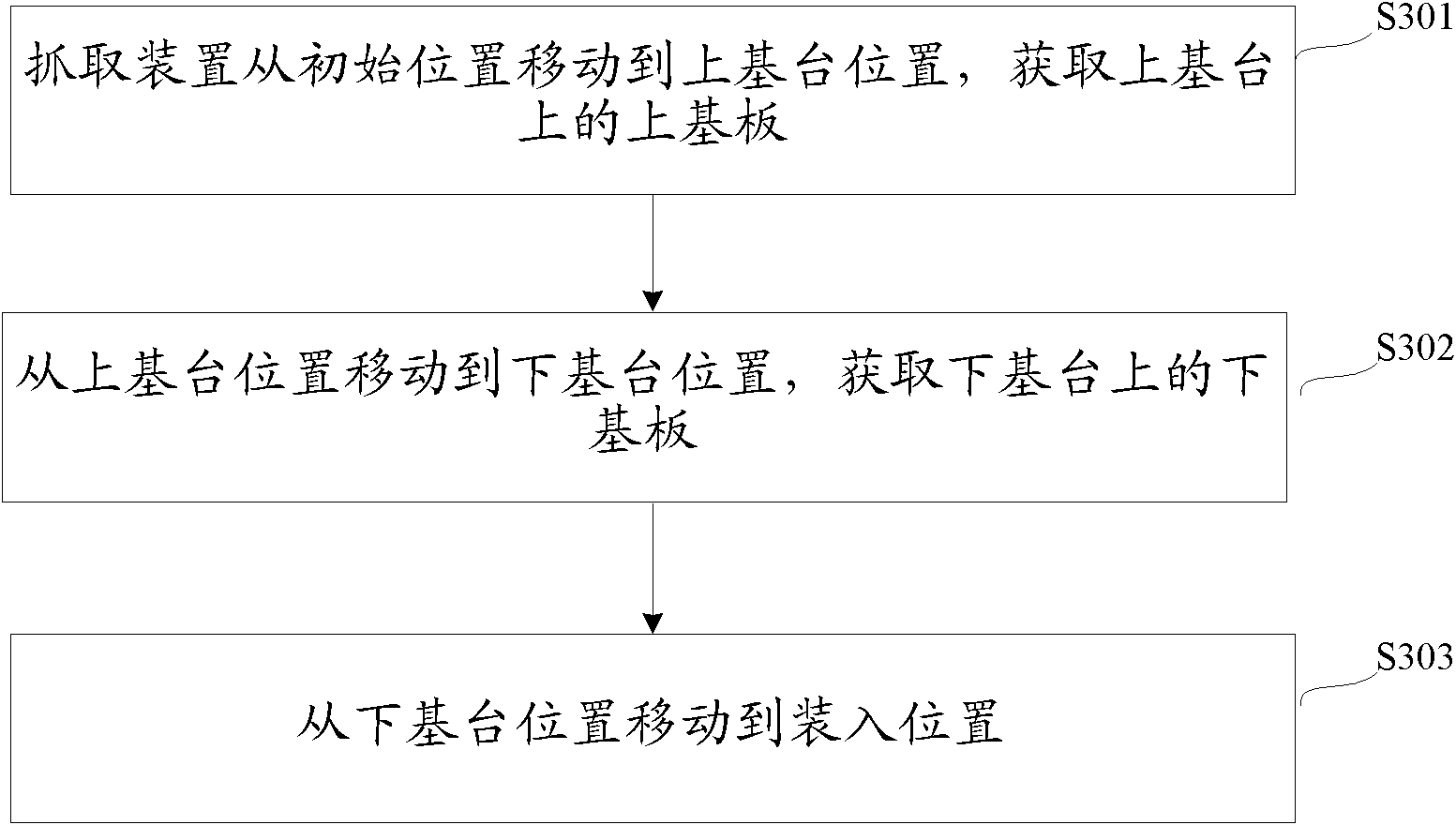

[0060] In this embodiment, the control device controls the specific actions of the grasping device according to the motion detection, such as Figure 6 shown, including the following steps:

[0061] S601: The grabbing device moves from the initial position to the position of the upper base according to the first control instruction sent by the control device, and acquires the upper substrate on the upper base;

[0062] S602: After the control device detects that the grasping device has acquired the upper substrate, it sends a second control instruction to the grasping device, and the grasping device moves from the position of the upper base to the position of the lower base according to the second control command, obtaining the lower substrate on the lower abutment;

[0063] S603: After detecting that the grabbing device has acquired the lower substrate, the control device sends a third control command to the grabbing device, and the grabbing device moves from the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com