Fixing structure of compressor

A technology of fixed structure and compressor, applied in the directions of household heating, lighting and heating equipment, space heating and ventilation, etc., can solve problems such as deformation of anti-vibration components, and achieve the effect of restraining deformation and alleviating stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

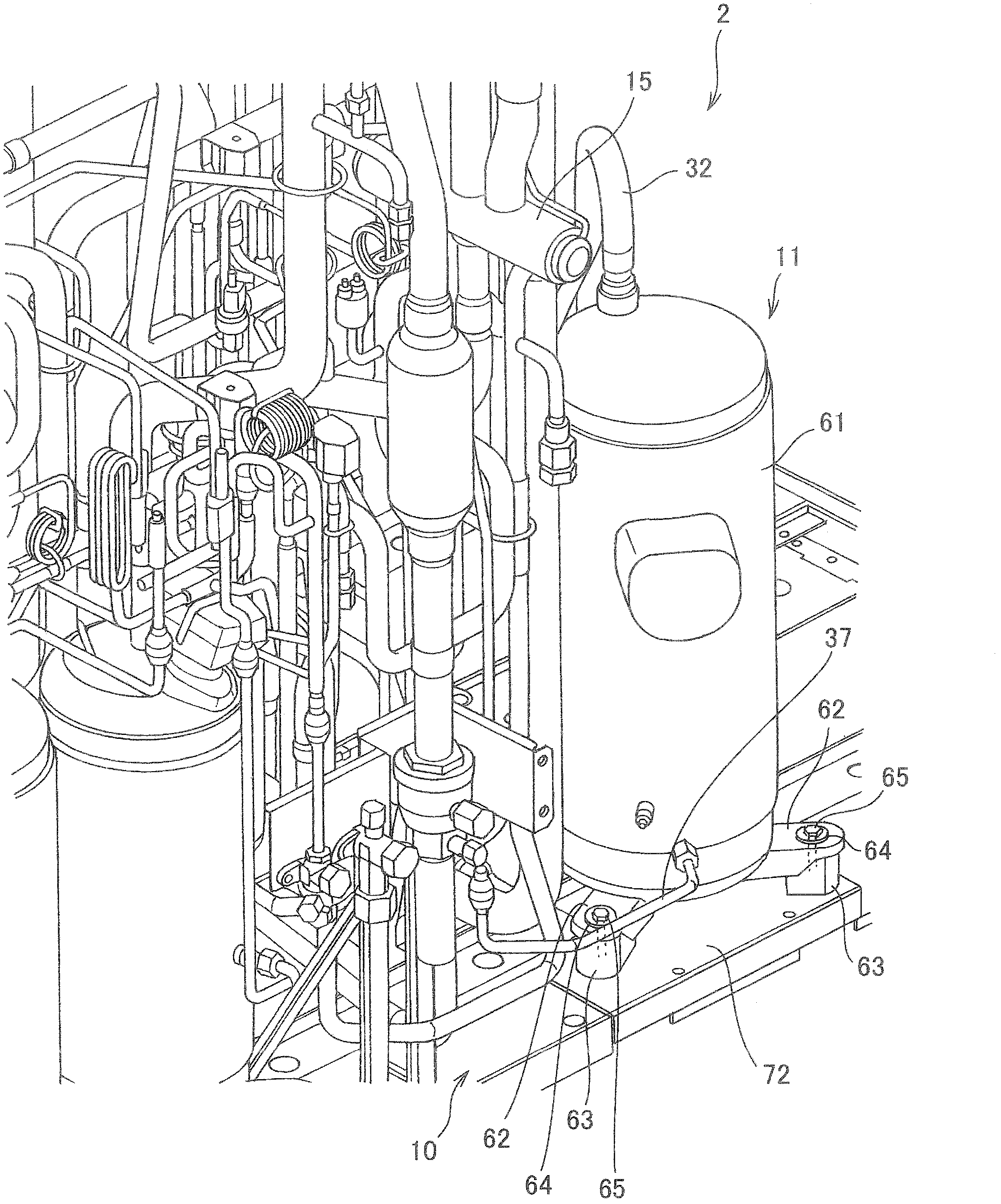

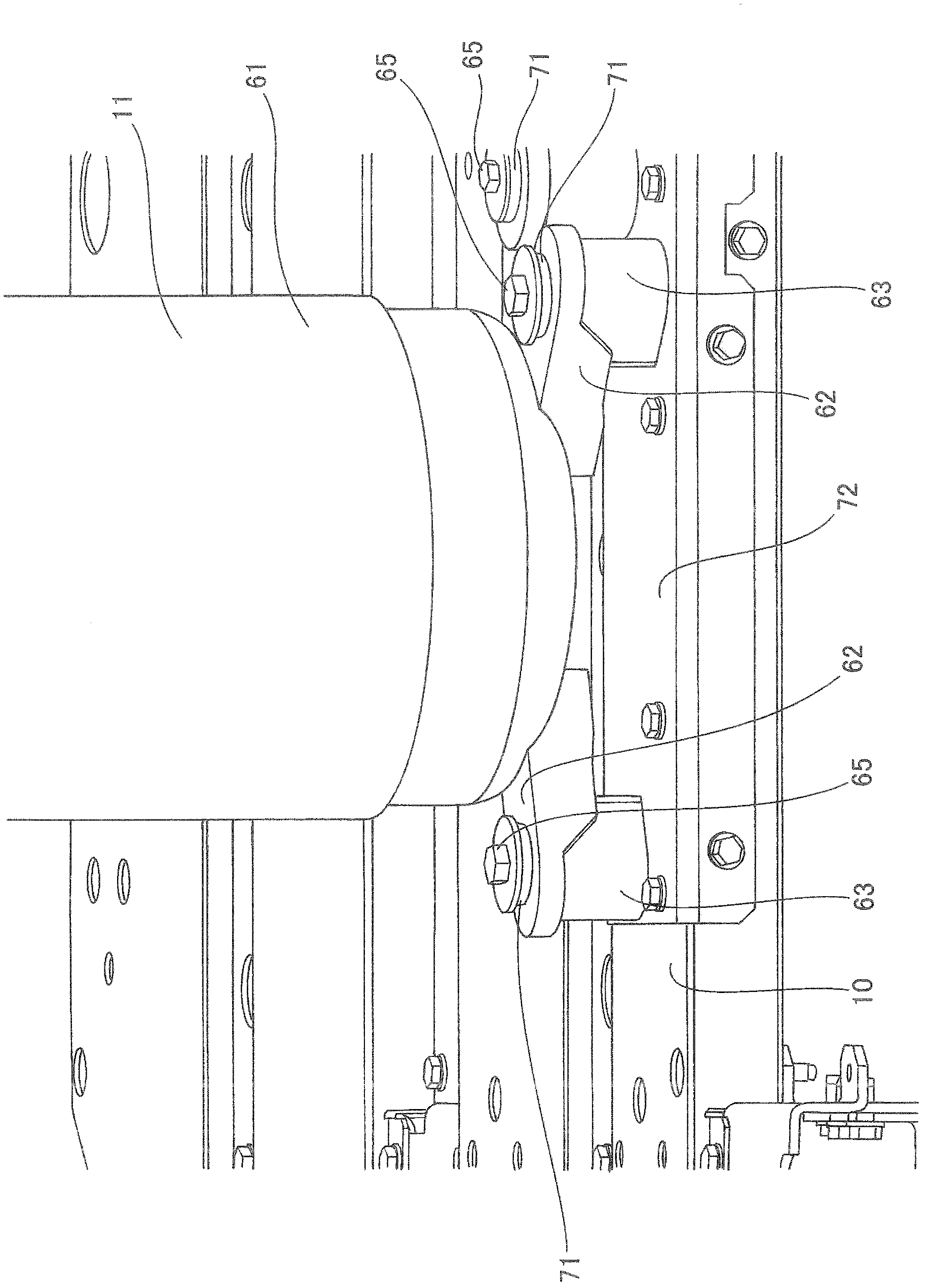

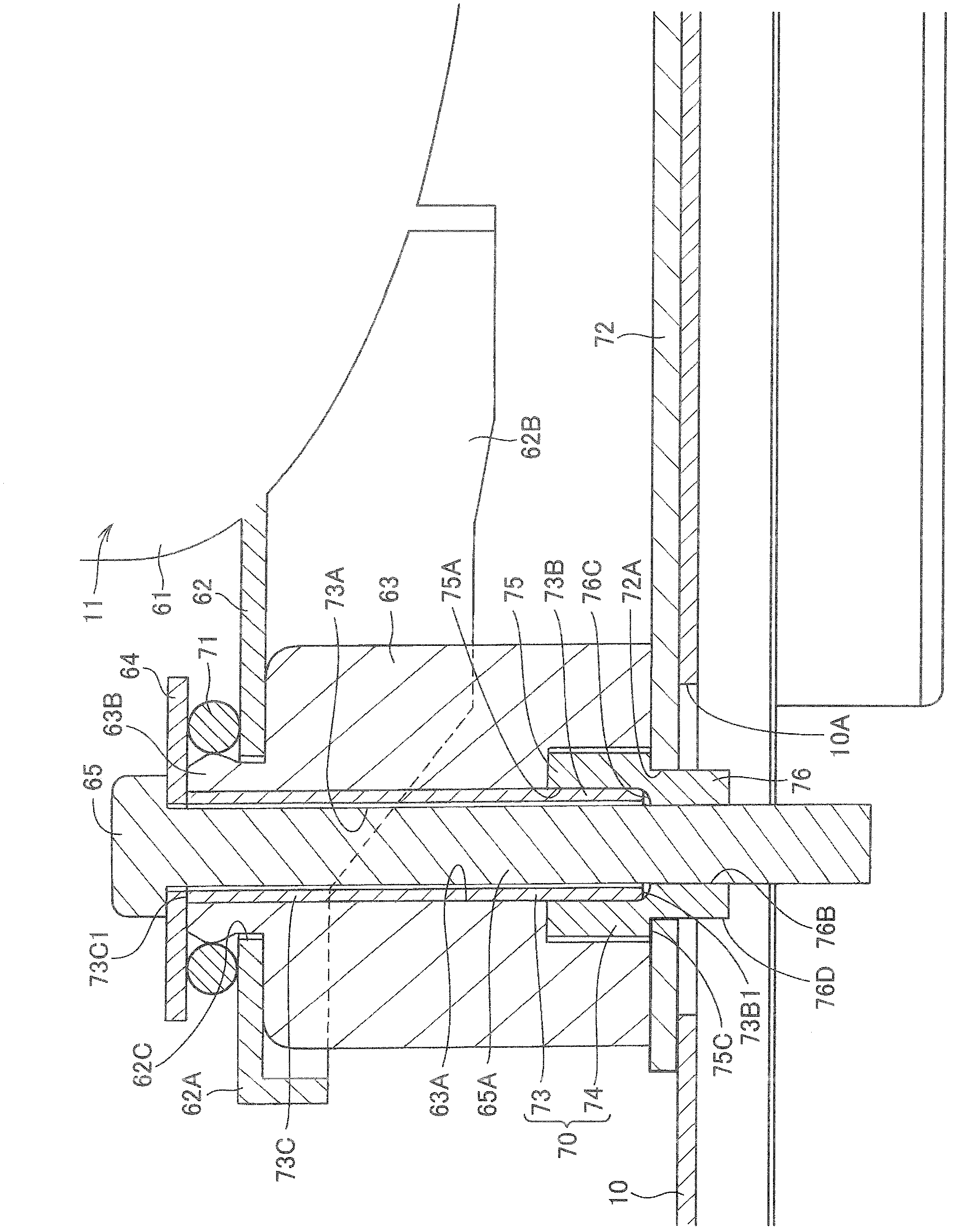

[0034] exist figure 1 In , symbol 2 represents the outdoor unit of the air conditioning device. The outdoor unit 2 is provided with a capacity-fixed (constant speed) compressor 11 and a four-way valve 15 on a base plate 10, and includes an accumulator, an oil separator, an outdoor heat exchanger, an outdoor expansion valve, The outdoor unit 2 is briefly configured by connecting each of the above-mentioned devices with pipes, such as a receiving box. The outdoor unit 2 is connected to the indoor unit through unshown gas pipes and liquid pipes.

[0035] The compressor 11 is a hermetic scroll compressor, and includes: a hermetic container 61; an electric component (not shown) housed in the hermetic container 61 and driven at a substantially constant rotational speed depending on the power supply frequency; A rotary compression element (not shown) that compresses refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com