Ultrahigh pressure mercury lamp and ultrahigh pressure mercury lamp lighting apparatus

A technology for lighting devices and mercury lamps, which is applied to high-pressure discharge lamps, lighting devices, discharge lamps, etc., can solve the problems of reduced illuminance and deformation of electrodes 90, and achieve the effects of suppressing deformation and maintaining high illuminance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

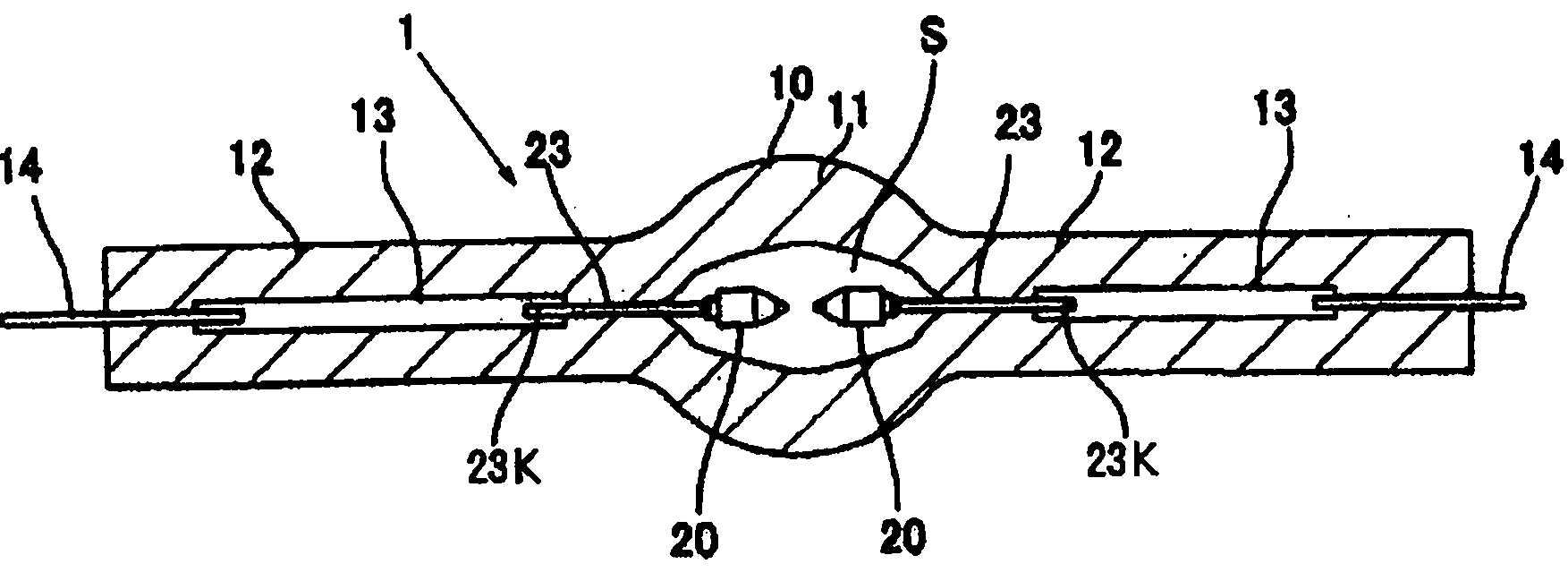

[0104] according to Figure 1 ~ Figure 4 With the configuration shown, AC lighting type lamps (A) to lamps (F) having the following specifications were produced. In addition, in the following specifications, the arc tube, the distance between electrodes, the material of the enclosure, and the electrodes are common specifications for all lamps.

[0105] The luminous tube is made of quartz glass, and the inner volume of the luminous part is 0.0825cm 3 .

[0106] The distance between electrodes was 1.1 mm.

[0107] Mercury, rare gas, and bromine as a halogen are enclosed in the luminous tube, and the amount of mercury enclosed is 0.29mg / mm 3 , the halogen filling amount is 3×10 -3 μmol / mm 3 .

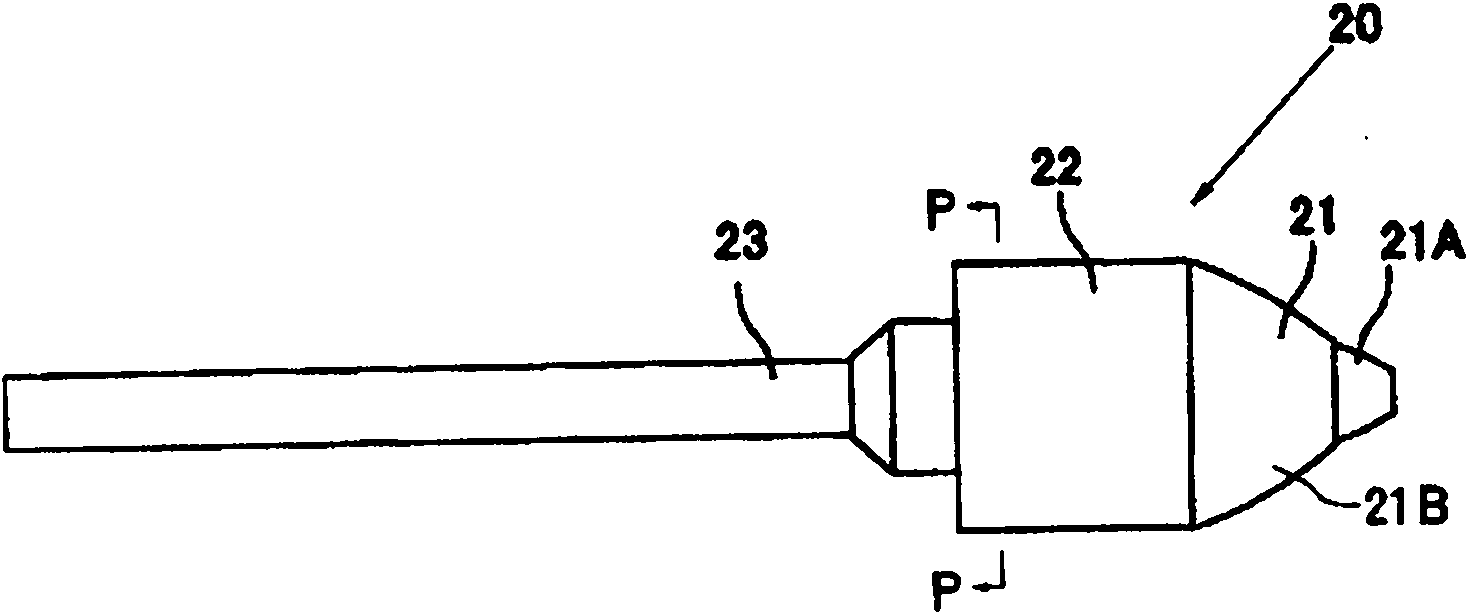

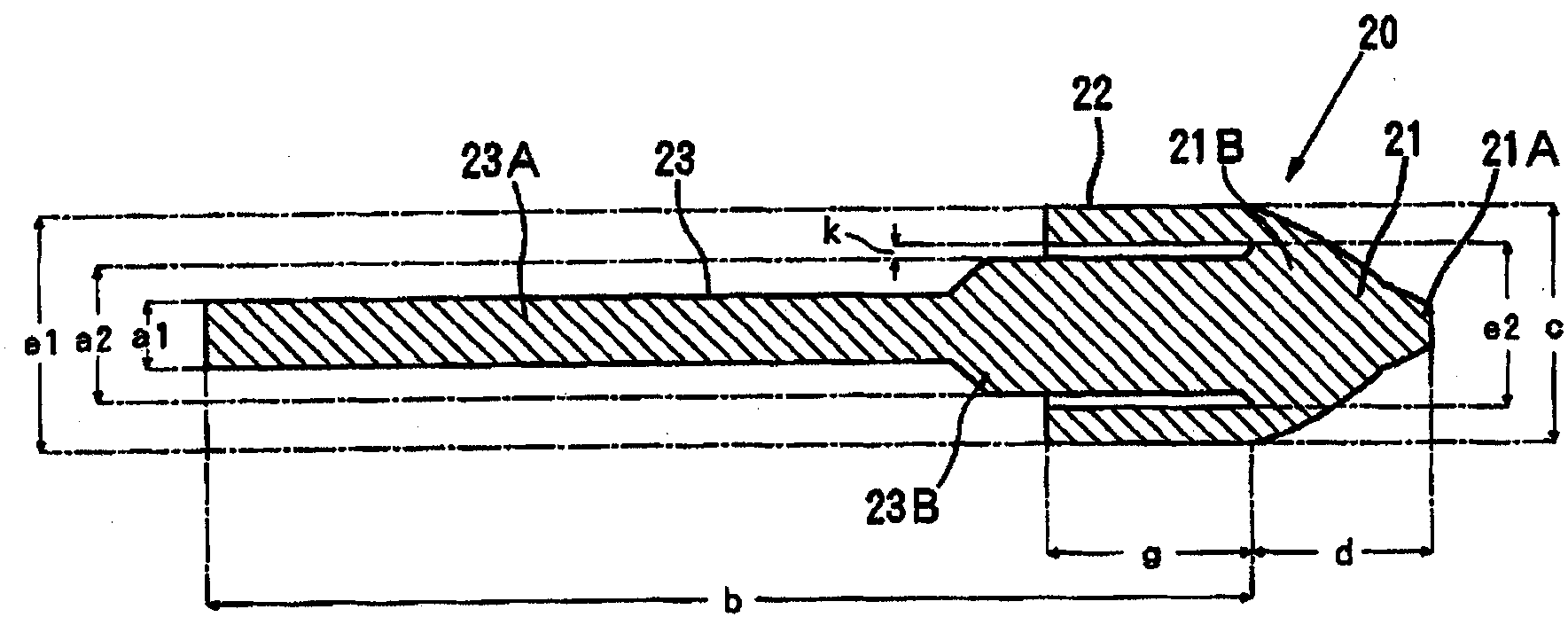

[0108] The electrodes are made of tungsten with a purity of 5N, and other specifications are shown in Table 1 below.

[0109] The input power is 275W.

[0110] Table 1

[0111]

[0112] For the lamps (A) to (F), an alternating current with a stable lighting frequency of 370 Hz ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com