Method for producing liquid crystal display element, liquid crystal display element, and polymer composition

A technology for liquid crystal display elements and manufacturing methods, applied in the directions of liquid crystal materials, chemical instruments and methods, coatings, etc., can solve problems such as hindering the use of resinous substrates, adverse effects on voltage retention, and producing display spots, etc., to reduce the amount of light, Displays excellent quality and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

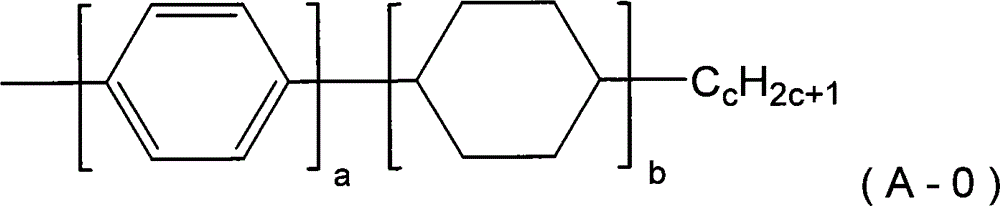

Synthetic example A-1

[0261] In a 2000mL three-necked flask, 83.07g (0.50mol) of terephthalic acid as dibasic carboxylic acid, 54.07g (0.40mol) of p-phenylenediamine as diamine and (0.10mol) 3,5- Diaminobenzoic acid-3-cholestanyl ester is mixed with 310.0g (0.50mol) triphenyl phosphite, 42.4g (1.00mol) lithium chloride, 250ml pyridine and 500ml N-methyl-2-pyrrolidone , stirred at 100° C. for 3 hours to react. After the reaction, the reaction mixture was poured into a large amount of ethanol to precipitate again, and 90 g of the polymer (A-1) (polyamide) was recovered by filtration.

[0262] A small amount of the obtained polymer (A-1) was dissolved in N-methyl-2-pyrrolidone to form a solution having a polymer concentration of 10% by weight, and the measured solution viscosity was 60 mPa·s.

Synthetic example A-2

[0264] (1) Synthesis of vinyl monomers with pretilt angle display sites

[0265] According to the following synthetic scheme 1, compound (a-2) was synthesized.

[0266]

[0267] Synthetic route 1

[0268] In a 2000mL three-necked flask, 384.64g (1.00mol) of 7-dehydrocholesterol represented by formula (a-2-0), 338.56g (1.20mol) of trifluoromethanesulfonic anhydride and 202.2g (2.0mol) of trifluoromethanesulfonic anhydride Ethylamine was dissolved in 840 mL of dichloromethane, and reacted with stirring at -30° C. for 1 hour in a nitrogen atmosphere. Next, distilled water was added to the reaction mixture in small amounts each time, and after the reaction was stopped, 300 mL of ethyl acetate was added, followed by washing with dilute hydrochloric acid and distilled water. After dehydrating the organic layer over magnesium sulfate, the solvent was removed to obtain a solid.

[0269] In a 500mL three-necked flask, in a nitrogen atmosphere, the above solid, 0.112g (0.0005mol...

Synthetic example A-3

[0275] In a 300mL four-necked flask equipped with a stirring rod, a three-way valve and a thermometer, add 15g (0.033mol) cholestanyl methacrylate, 13g (0.090mol) glycidyl methacrylate, 7.2g ( 0.084mol) methacrylic acid, 7.2g (0.069mol) styrene and 7.2g (0.044mol) N-cyclohexylmaleimide, then add 53g as solvent ethanol, 2.2g as polymerization initiator 2,2 '-Azobis(2,4-dimethylvaleronitrile) and 0.96 g of α-methylstyrene dimer as a molecular weight regulator. This was boiled in a nitrogen stream for about 10 minutes, and the system was replaced with nitrogen, and reacted at 70° C. for 5 hours under a nitrogen atmosphere to obtain a solution containing 48% by weight of a polymer (A-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com