Intelligent verification system of main transformer oil temperature and winding temperature controller

A temperature controller and winding technology, applied in the field of main transformer oil temperature and winding temperature controller intelligent verification system, can solve the problems of low efficiency of verification process, human health hazards, high labor intensity of personnel, etc., and achieve convenient pre-test maintenance and use , The effect of high protection level and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

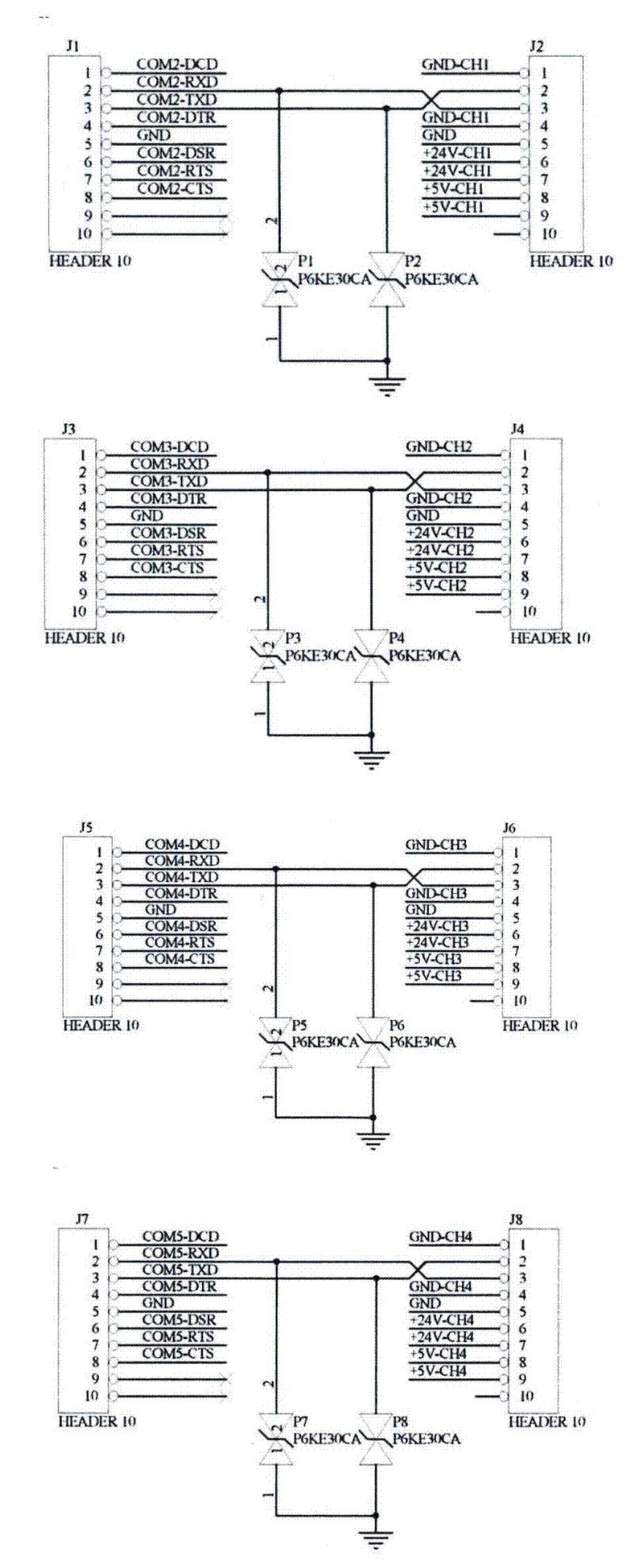

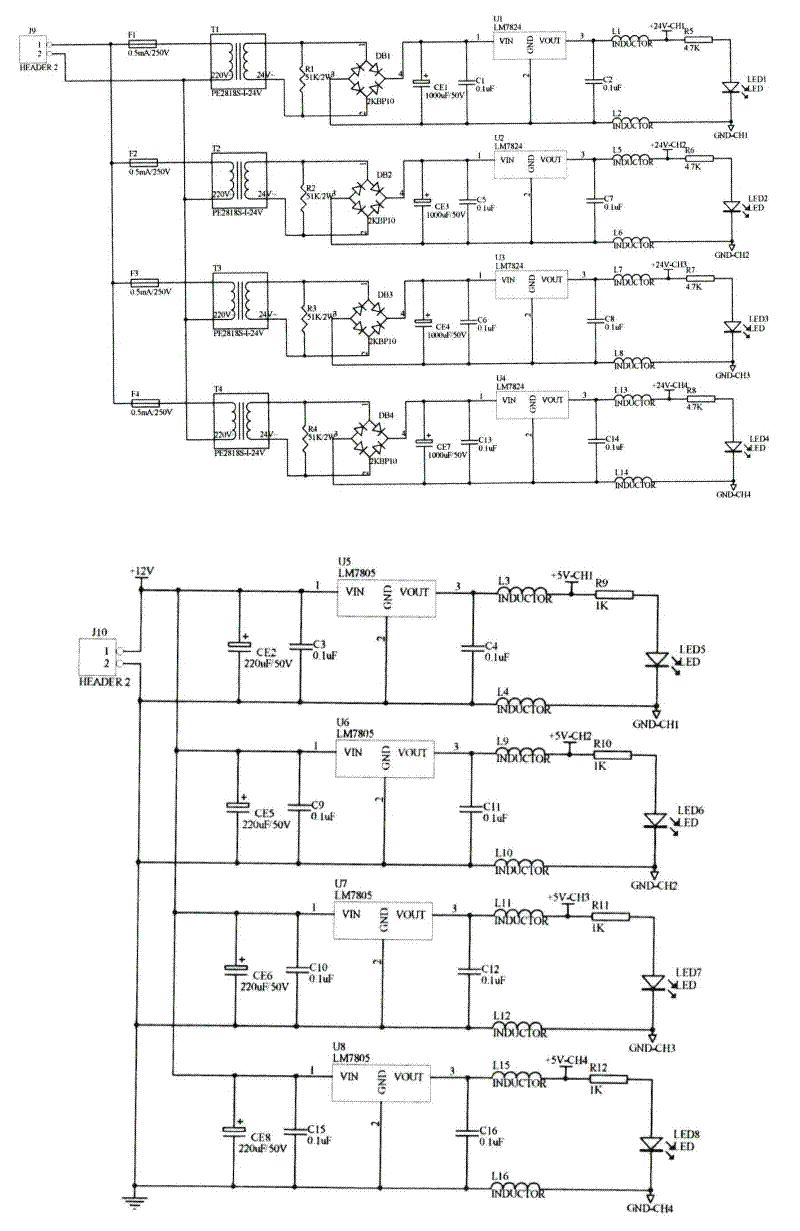

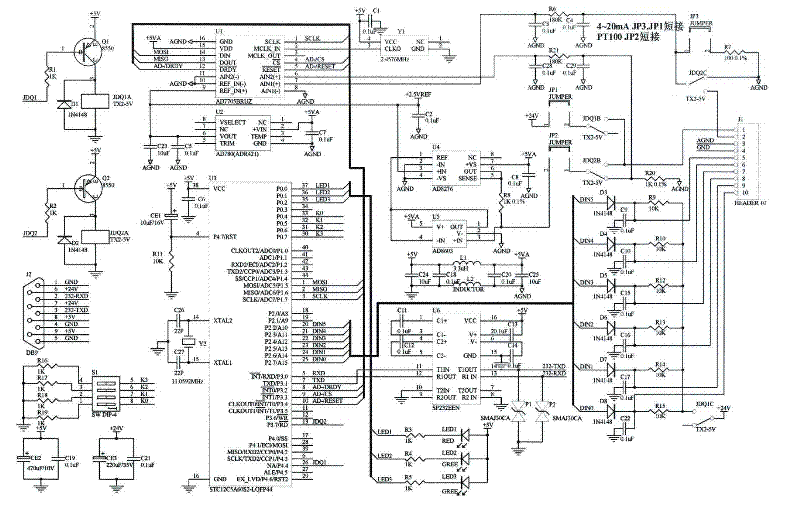

[0019] see figure 1 , figure 2 It can be seen that the present invention includes an industrial control host 1 , a data acquisition head 2 , a standard temperature bath 3 , and a temperature controller 4 to be tested. The industrial control host 1 is a dedicated development platform using an open instrument platform. The external equipment includes the data acquisition head 2, and the standard temperature tank 3 adopts the American standard temperature tank FLUKE9171. Each detection channel is composed of a data acquisition head 2, a standard temperature tank 3 and a temperature controller 4 to be detected, forming independent detection channels CH1, CH2, CH3, CH4. One end of the data acquisition head 2 is connected to the industrial control host 1 through the RS232 interface, and the other end is connected to the temperature controller 4 under test; the sensor 4-1 of the temperature controller 4 under test is inserted into the standard temperature tank 3 .

[0020] The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com