Automatic labeling equipment

A kind of equipment and automatic technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problem of high scrap rate, low quality of labeling, and it is difficult to ensure the correct position of self-adhesive paper. and other problems, to achieve the effect of improving the quality of labeling and improving the efficiency of labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

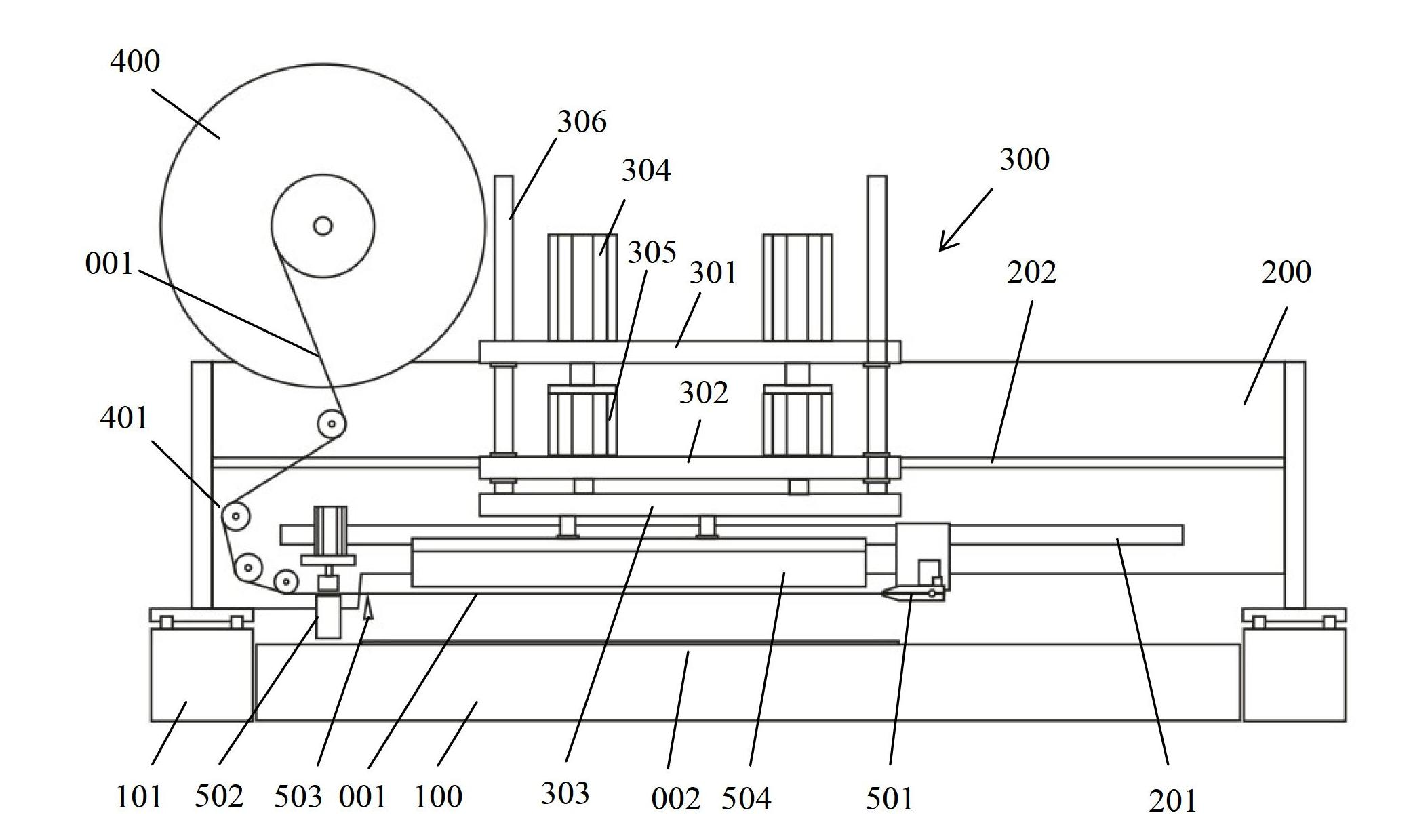

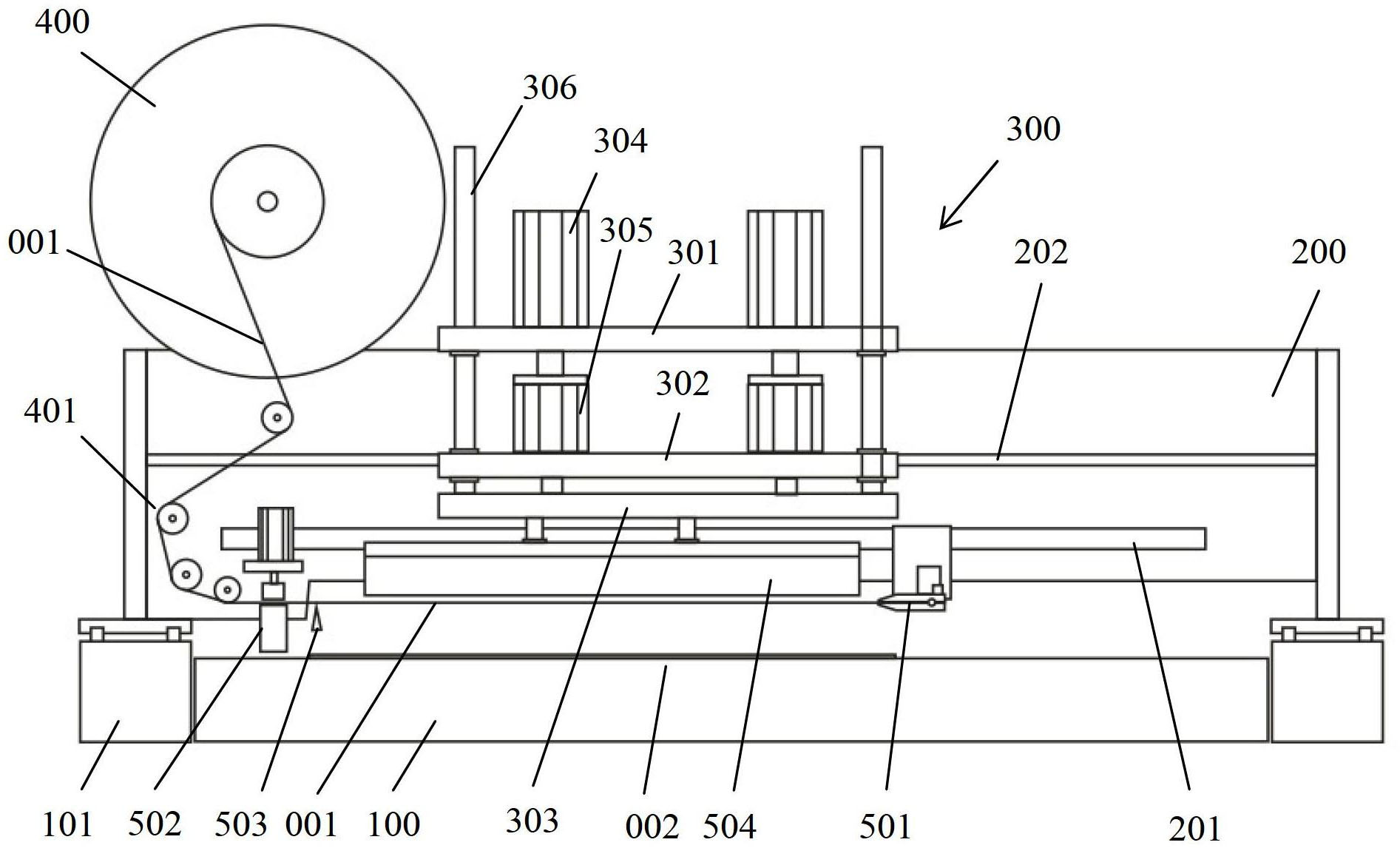

[0015] As shown in the figure, the automatic labeling equipment of the present invention includes a backing paper platform 100, a lateral support beam 200, a vertical pneumatic drive assembly 300, a reel 400, a first chuck 501, a second chuck 502, and a cutter 503 And strip suction plate 504.

[0016] Wherein, there are sliding seats 101 on both sides of the backing paper platform 100, and the transverse support beam 200 is located on the two sliding seats 101, and can slide back and forth along the sliding seats 101, so that the labeling position can be adjusted longitudinally. There is a first transverse slide rail 201 at the lower part of the transverse support beam 200 . A second sliding rail 202 is provided on the upper part of the transverse support beam 200 .

[0017] The vertical pneumatic drive assembly 300 is installed on the second slide rail 202 through the support frame, and can move laterally along the second slide rail 103, so as to adjust the labeling position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com